LightForce Orthodontics, a provider of custom 3D printed orthodontic brackets, has raised $14M in its latest round of Series B funding. The round was led by Tyche Partners, with additional investments from Matrix Partners and AM Ventures.

LightForce’s 3D printing technology is commonly used by orthodontists to produce custom individualized braces for patients, resulting in a reduced number of follow-on visits for bracket adjustments. The capital will be used to further develop this technology while scaling LightForce’s operations to meet the increasing demand for orthodontic procedures.

Dr. Alfred Griffin, CEO, and co-founder of LightForce, states: “In the last year our business has doubled every quarter, and that tells me that LightForce has pinpointed a true need within the orthodontic space. We look forward to growing with our investors, partners and the orthodontic community to provide the best experience and outcomes for our patients.”

Weiji Yun, Managing Partner at Tyche Partners, adds: “Alfred and Lou’s inspirational vision offered us an opportunity to expand our 3D-printing investment portfolio and the company’s rapid growth is proof that the industry is primed for a solution that improves the orthodontic experience for patients and doctors alike.”

One size fits all

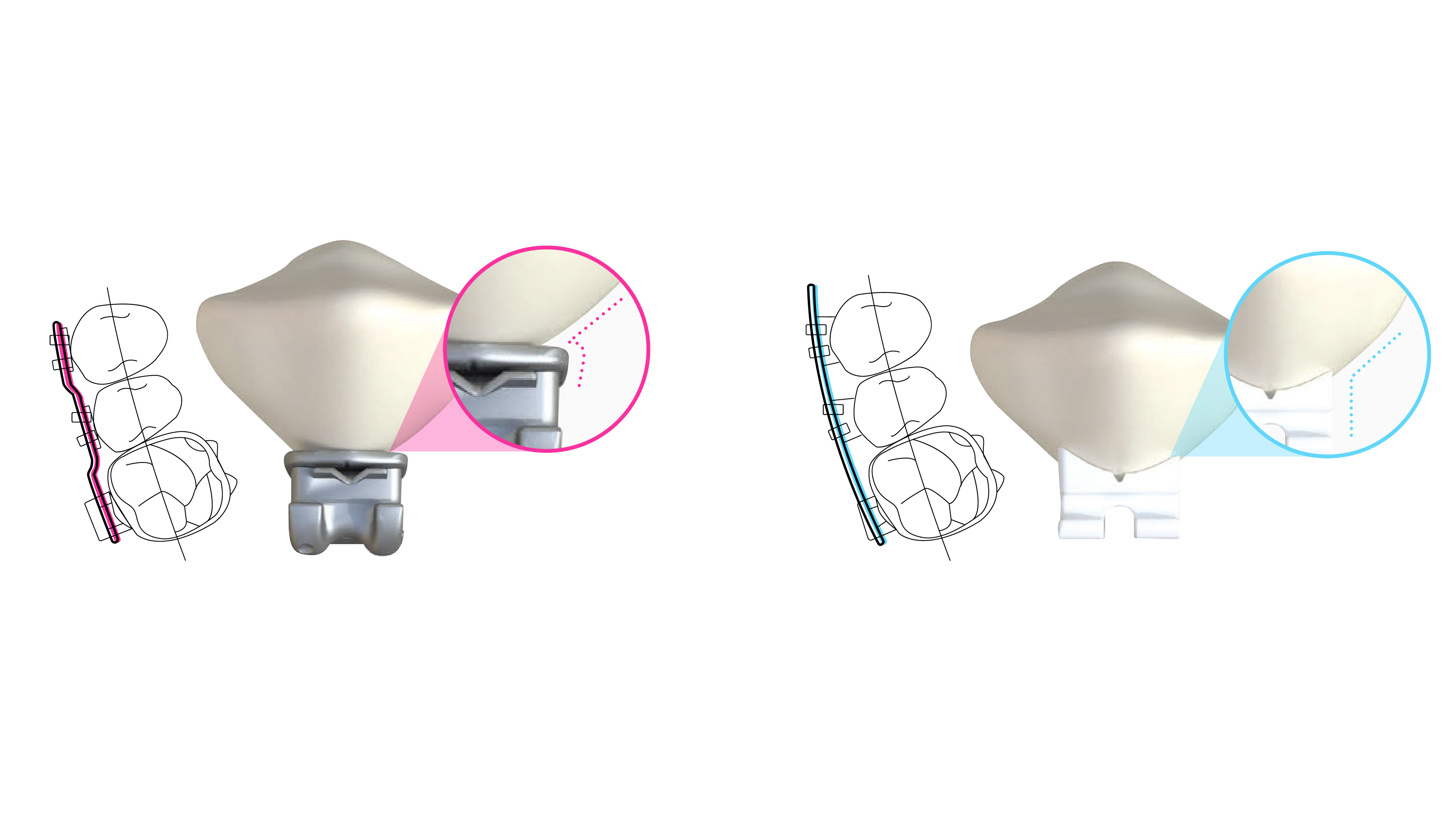

Despite everyone’s faces, jaws, and teeth being very unique, many of the braces used today follow the age-old ‘one size fits all’ philosophy. The LightForce ethos goes against this, instead enabling mass customization and personalization with patient-specific bracket systems.

Orthodontists who opt for the LightForce service will begin by sending the company a 3D scan of a patient’s teeth along with their treatment plan. LightForce will then print the corresponding brackets and trays in-house before sending them directly to the practice. The parts are made of a 3D printing dental ceramic with mechanical properties almost identical to those of traditional injection-molded brackets. The LightForce treatment reportedly results in shorter lead times, fewer appointments, and an overall more efficient experience.

Griffin adds: “Braces haven’t changed in fifty years yet are by far the most common treatment tool; aligners are esthetic and patient-specific, but because of patient compliance and biomechanical limitations, they only serve a small fraction of our patients today. This opportunity to help patients and orthodontists was why we applied modern 3D software and mass-customization to what we know today as braces.”

3D printing in the dental sector

The dental industry has benefited greatly from advancements in 3D printing technology, with implants and restorations becoming more common year-on-year. To facilitate this rising demand, specialist dental resins are required.

Earlier, in July, SLA 3D printer manufacturer Formlabs announced the release of six new resins, three of which were specifically aimed at dental professionals. The first resin, Dental LT Clear V2, is great for long-term splints and occlusal guards while the second resin, Custom Tray Resin, is designed for custom impression trays. The final resin, Temporary CB Resin, is specifically for the production of durable seven-unit bridges and other smaller temporary restorations lasting up to 12 months.

Elsewhere, in Switzerland, Saremco Dental AG previously released a proprietary photopolymer resin for 3D printed permanent restorations such as crowns, inlays, onlays, and veneers. Prior to its release, the CROWNTEC resin was subjected to extensive testing at the University of Zurich, which revealed a Young’s modulus of 4.5GPa and a mean loading force of 1479N.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D printed LightForce bonding tray. Photo via LightForce.