Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

Materials specialist LEHVOSS Group is heading up a new Innovate UK project to identify, develop, and optimize materials and processes for overprinting organic sheets and other components.

Throughout the project, the company will lead a consortium made up of the University of Exeter, polymer specialist Victrex, 3D printing service provider FDM Digital Solutions, wiring loom specialist Q5D Technology, and topology optimization software firm GRM Consulting.

The goal of the project is to produce new material combinations and improved processes for overprinting within industries such as automotive, aerospace, medical, and defense, as well as to develop new applications, hardware, and software for the technology.

“Additive manufacturing is already established in serial applications today,” said Dr. Thiago Medeiros Araujo, Global Product Management of LEHVOSS Group’s LUVOCOM 3F filaments and head of the project. “This project aims to expand its application providing a suitable alternative to overmolding, which can be very cost intensive and time consuming.

“We are very pleased to lead this project together with our extremely capable and experienced consortium partners.”

Overprinting with high-performance polymers (OverHIPP)

Overprinting is a technique for designing multi-material parts when different materials are needed in various components of a part. Typically, a print is started and then paused midway whereby components can be embedded into the 3D print job. Then, the print process is resumed and allowed to 3D print over the components that have been embedded.

Overprinting can be used to develop more integrated products, such as embedding electronic components within a 3D printed part, or when two materials are required for the same component for their respective material properties.

Innovate UK’s OverHIPP project is seeking to expand upon the capabilities of overprinting by developing new material combinations and improved processes, as well as discovering new applications for the technology, specifically electronic components, sensors, structural components, and medical instruments and aids.

During the project, which is set to run until May 2023, LEHVOSS Group will lead the consortium in advancing unique hardware for printing high-performance polymers onto non-planar surfaces, and developing new software to drive the optimal positioning and orientation of materials and parts during the overprinting process.

The partners will focus on developing and optimizing these materials and processes for overprinting organic sheets and other components, and will produce demonstrator components suited to targeted industries including the automotive, aerospace, medical, and defense sectors.

Developing printing materials for OverHIPP

LEHVOSS Group comprises a group of companies in the chemicals sector that develops, produces and markets chemical and mineral specialties for various clients.

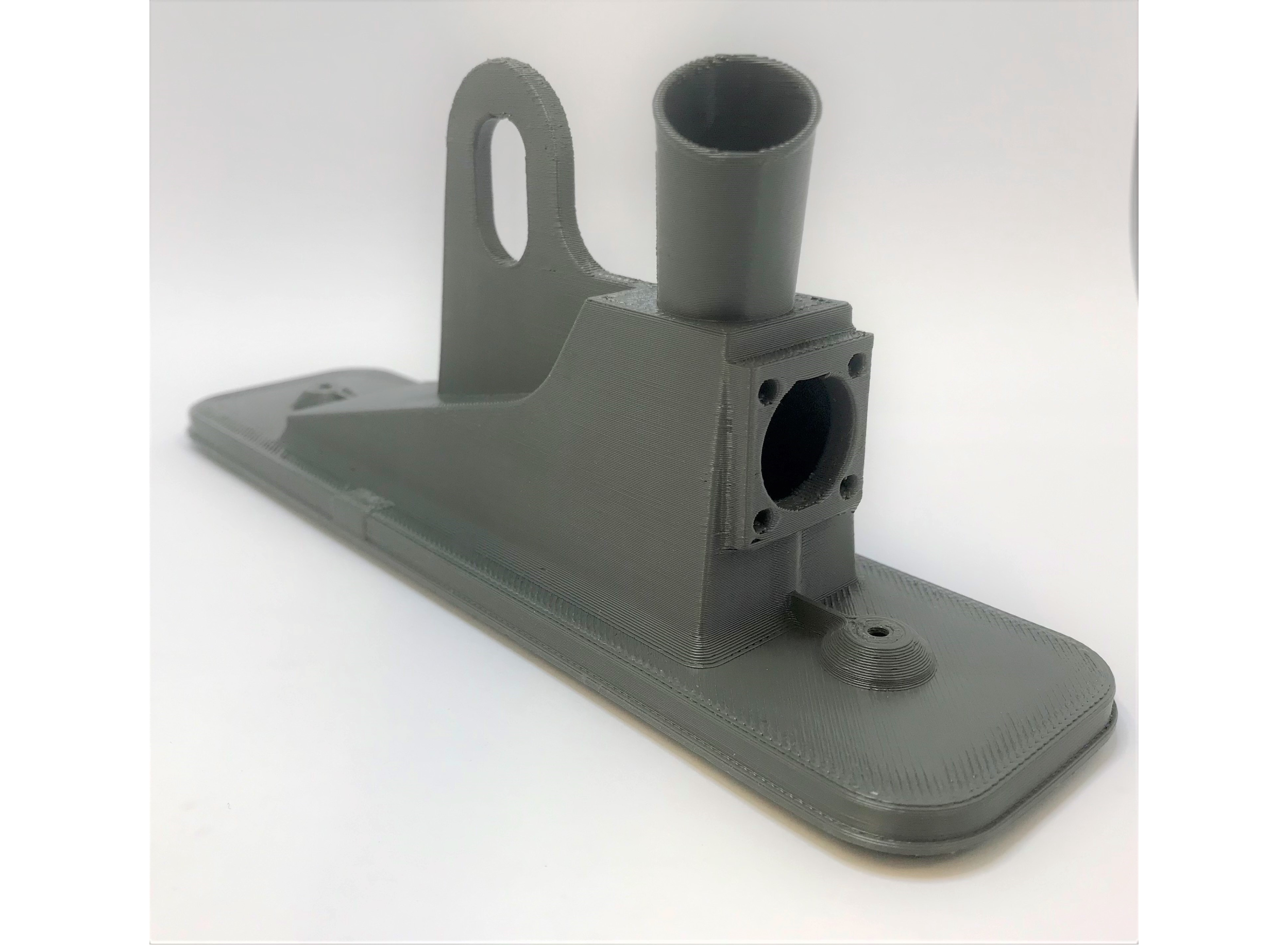

Alongside spearheading the consortium, the LEHVOSS Group will develop and provide the polymeric printing materials for the Innovate UK project, specifically high-performance polymers such as PPS, PEI, and PAEK. Based on these and other polymers, the company offers a range of customized materials for Fused Filament Fabrication (FFF) and Fused Granulate Fabrication (FGF) 3D printing processes.

In March last year, LEHVOSS Group announced a partnership with High Speed Extrusion (HSE) 3D printer manufacturer Essentium, to develop a line of high-performance materials for 3D printing consisting of PEEK and High-Temperature Nylon (HTN). The materials were specifically engineered to meet the standards of high-performance applications in the aerospace, automotive, oil and gas, biomedical, and electronic manufacturing industries.

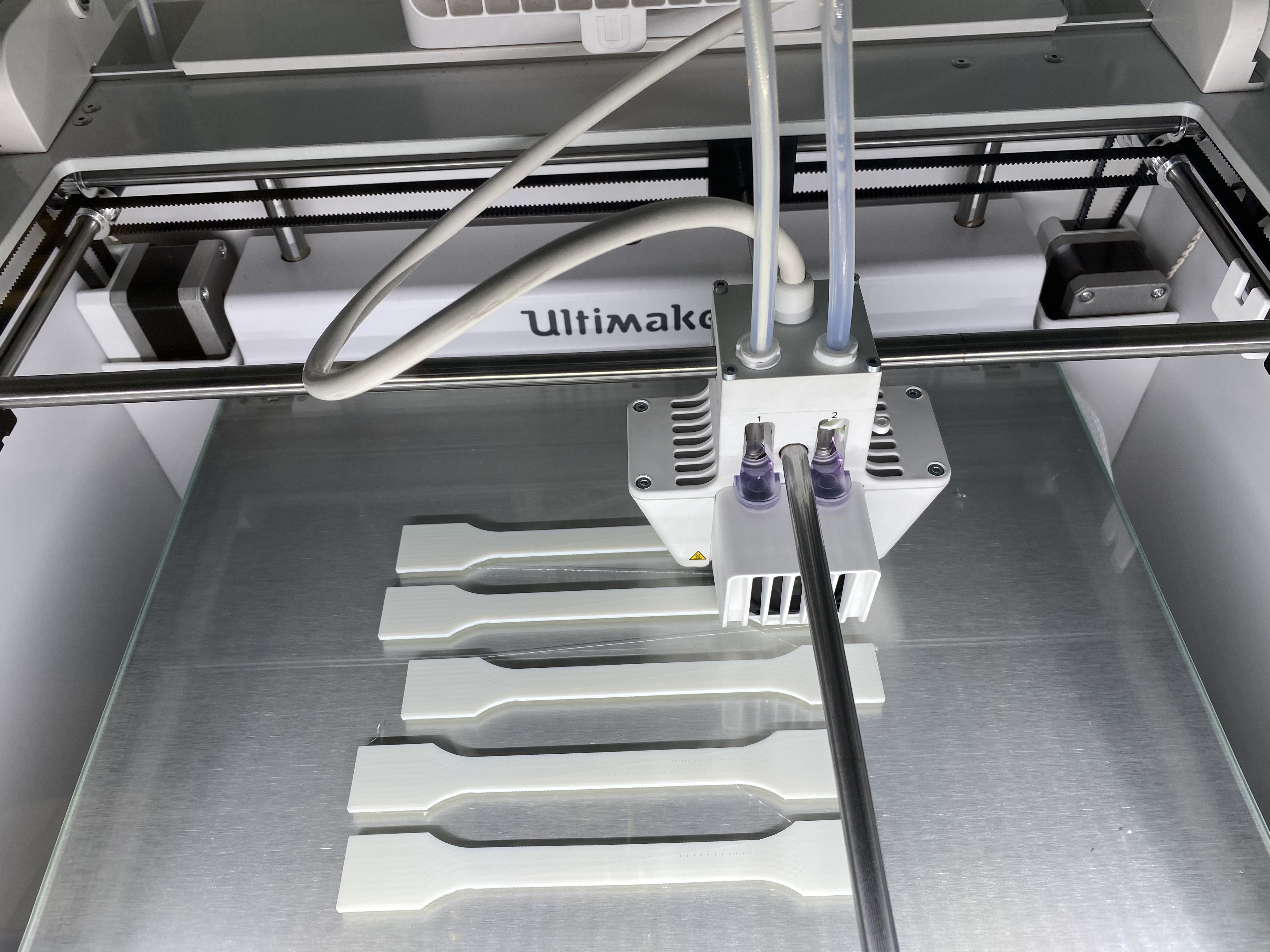

Towards the end of the year, LEHVOSS Group and 3D printer manufacturer Ultimaker jointly received a first-of-its-kind printing process certification from TÜV SÜD for the 3D printing process combining LEHVOSS’ LUVOCOM 3F filaments on Ultimaker’s S5 Pro Bundle. The LUVOCOM 3F filament series comprises four different materials, two of which are carbon-fiber reinforced. They are based on either PA or PET, and are specially formulated for high-performance applications.

Advancing 3D printing materials and processes

Established as an advisory body in 2004 by the British government, Innovate UK became an independent body in 2007 with the goal of accelerating the development of advanced technologies. In the past year alone, the organization has provided funding to multiple 3D printing-based projects to accelerate the technology’s progress.

In November 2020, the organization awarded Fixie, a 3D printing service for built environment professionals, and Enable Manufacturing, a metal 3D printing service provider, grants to expand their 3D printing activities within their respective sectors as part of its Sustainable Innovation Fund.

The following month, Innovate UK awarded Smart Grants to social enterprise and University of Cambridge spin-out Blue Tap to support the technical development of its 3D printing-based water purification technology, and to University of Liverpool spin-out Meta Additive to further advance its proprietary binder jetting technology.

At the beginning of this year, Innovate UK backed FastWireAM, a new R&D program spearheaded by hybrid systems specialist Hybrid Manufacturing Technologies (HMT). The project aims to fast-track the development of a new compact wire-feed system for laser-based 3D printing.

Most recently, post-processing specialist Additive Manufacturing Technologies (AMT) received an Innovate UK grant worth £97,000 to develop a new organic solvent for the post-processing of thermoplastic elastomer materials, such as TPU.

Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows LUVOCOM 3F filament. Photo via LEHVOSS.