A mysterious YouTube video and Twitter feed appeared recently that demonstrated a great mix of augmented reality, simplified CAD software and 3D printing called Lego X. The program let’s users create 3D printable models by simply building the basic shape out of Lego bricks and then converting them into 3D models.

For the average consumer, CAD design programs – even the “easy” ones – are still pretty complicated for someone with little to no experience using them. There are a few newer options that have simplified the process so much that models can be designed on touchscreen devices, but even those can be difficult to manage for someone incapable of conceptualizing 3D objects designed in a 2D space. The technology and software in Lego X solves this problem in a rather interesting and innovative way.

All of us can build using Lego bricks. Even those of us who may not have a knack for design, we can all stick multi-colored blocks – Lego X uses Duplos in their demo video – together in order to build something. For most kids, Lego sets and building blocks are some of the first toys that we ever play with.

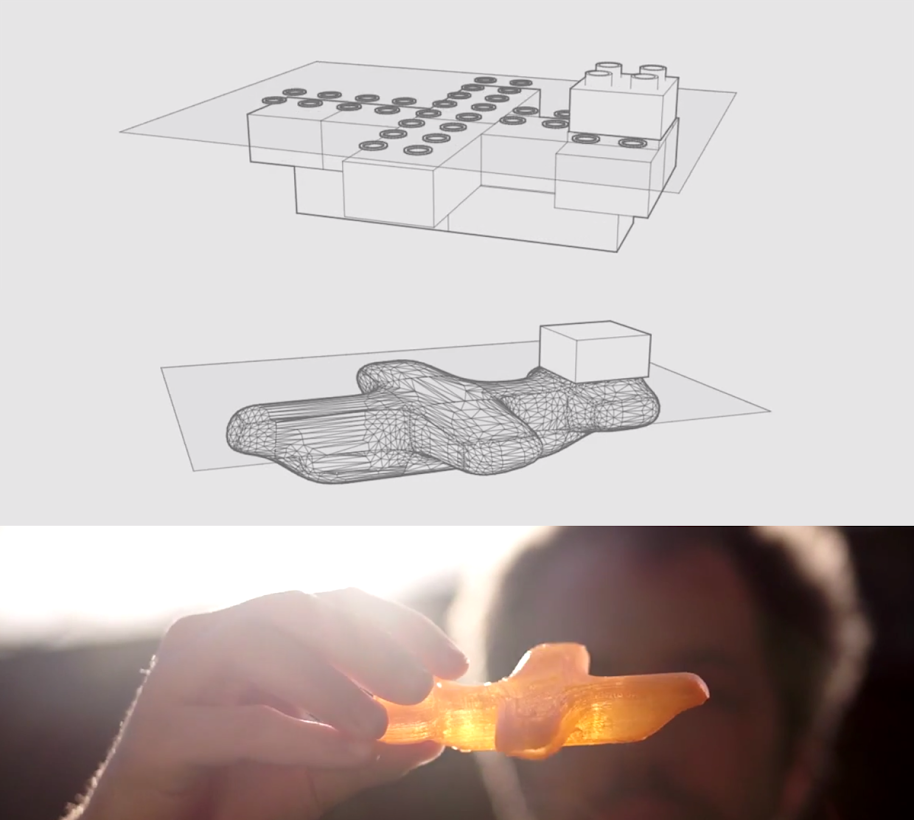

A group called Gravity Research Club has inserted small sensors into a collection of building bricks and matched them to corresponding virtual versions that can be viewed on a tablet. Cleverly using augmented reality to see the blocks being moved and connected in real time, Lego X can create virtual duplicates of whatever is built with the bricks. The blocks can be manipulated and rotated in real life, and the virtual models will match their movements. Once you attach two parts, the virtual models will snap together.

When a model has been built with the Legos in the real world, the software will use an algorithm to smooth out the edges and corners of the virtual Lego blocks. The new model will maintain the general shape of the object, but remove any sign that the original design was made from Legos. This smoothed out file can then be converted to a 3D printable model that can be scaled to any size.

Take a look at the demonstration video here:

I’m sure most professionals who use CAD software would love to spend their day prototyping with Lego bricks, and I can’t blame them. But beyond being fun, I can definitely see the appeal of building some rudimentary models in the physical world first. If you change your mind or have a wild idea, the only thing that needs to be done to reverse your steps is to pull the bricks apart.

Now, it should be said that, from what I can tell Lego X is not actually associated with Lego. But it has obvious applications for STEM education, especially for students who may not think they are capable of using or are intimidated by the complexity of the software. I’m certainly going to be keeping an eye on this mysterious group of Lego hackers, because what they’ve done so far it’s pretty cool.