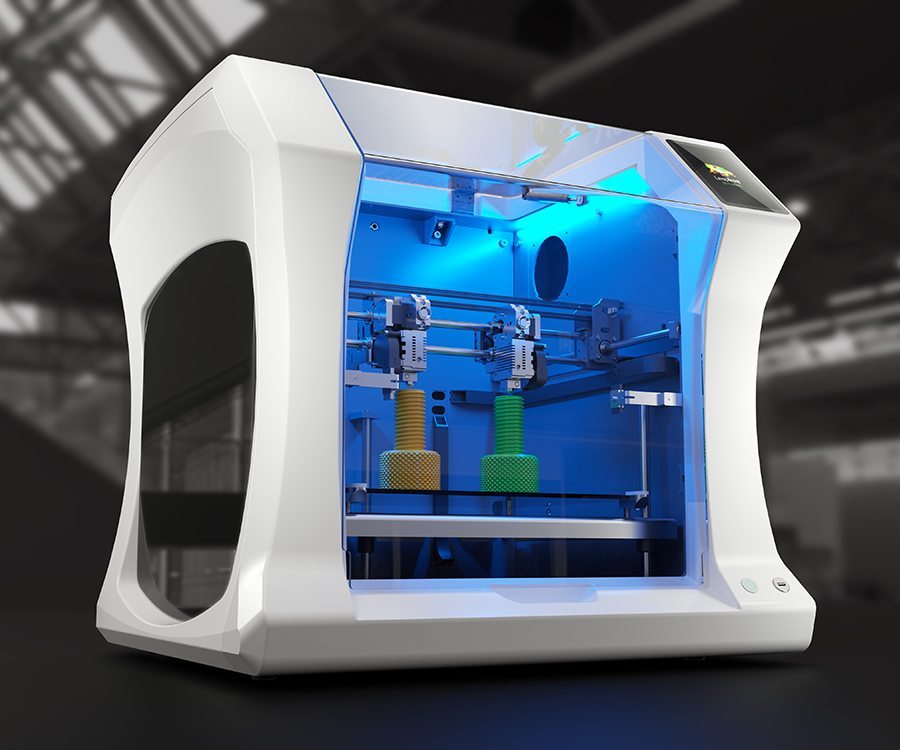

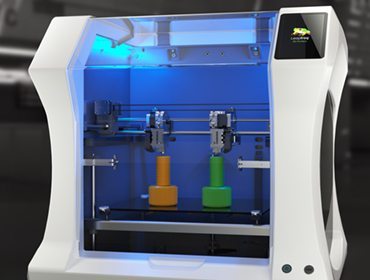

Leapfrog, a company that is well established in the world of 3D printing, have released a new dual head printer dubbed the Bolt. It has all the bells and whistles, including Leapfrog’s latest software (which is marketed as simple, but powerful), and high grade hardware and technology developed by the company. It even has an inbuilt webcam so you can watch the printing progress remotely. The goal of the Bolt is to make 3D printing easier, faster and more reliable. So lets see what’s under the hood.

Dual head

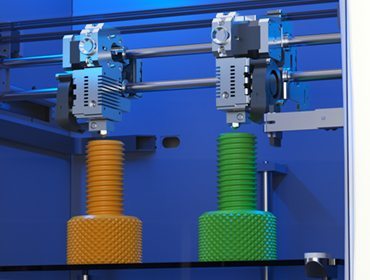

Dual extrusion 3D printers open printing to a wide range of possibilities. The opportunity to mix materials to create unique parts and using two different colors simultaneously are just the tip of the iceberg. The main advantages are straight forward; no cross-filament oozing, more control per filament and doubling the print speed with replicator mode and mirror mode on the large build platform this 3D printer. This leads to cleaner dual prints and 2 times the print speed.

Multiplatform Software

The Bolt software can be accessed on the large touchscreen or by any device with a browser like your PC, phone and tablet using WiFi. It is not necessary to use a thumb drive anymore, just transfer your file to the Bolt storage from your PC, and start that print from any of your devices.

With the ease of different user interfaces, settings can be blocked or full control can be given per user. The integrated webcam provides for a remote view and the software gives you live information on the time and filament left as well as active control on your current print job keeping you in charge at any given moment.

Replicator and Mirror modes

Leapfrog’s latest technology provides this 3D printer with two separate heads which opens up new capabilities. When starting a print, the dual heads can automatically mirror, or copy your part with the push of a button. Both features actively double the production speed of the Bolt.

Replicator mode: This creates an exact replica of the printed piece, so if you need multiples of your print this will cut the printing time in half.

Mirror mode: This creates a mirrored copy on the bed of your print. This is useful for making moulds, orbs, left-right parts, without creating its counter part.

Material capabilities

Dual extrusion 3D printers are best used combining different materials. Through the direct drive mechanism, the material flow is exactly controlled, even in the case of flexible materials. The high temperature hot-end allows temperatures of up to 360°C and the heated bed provides for better adhering between bed and filament. Together these characteristics allow the Bolt to print with a wide variety of materials.

Other features

The closed environment of the printer means the climate is better for hotter materials, reducing the warping and splitting between layers. Also, with the addition of the activated HEPA carbon filter, no pesky toxic vapours will be released, making it much safer to be around.

The Bolt also boasts a large 7″ touchscreen, making the software a bit easier to navigate on the printer.

At £4,299.00 (excluding VAT), it is pretty pricey, but this isn’t intended for the individual. With education and professionals in mind, Leapfrog have created a relatively inexpensive machine that is capable of a great deal. You can see the full specifications here.

About Leapfrog

Leapfrog 3D Printers aims to make high tech 3D printing techniques and materials easy to use and affordable for a broad user base. Adding value for business and educational customers is the core of their existence. Leapfrog forms partnerships with different types of professionals who use their desktop 3D printers and learn from their experience. This way they can help them and other potential users to capture all the benefits of 3D printing for their application. Whether it is engineering, product design, medical purposes, architectural design or education, together with them, Leapfrog Creates the Future.

Leapfrog 3D Printers was founded in 2012 when AV Flexologic, a Dutch manufacturer of machines for the flexographic industry, was in need of producing prototypes and unavailable spare parts for their machines. After evaluating the poor or expensive options available in 3D printing at that time, the decision was made to develop the ultimate easy to use, sturdy and versatile 3D printer. This is how the classic Creatr was born.