Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Private US aerospace firm Launcher has raised $11.7 million in a Series A funding round as it seeks to ramp up the development of its first orbital launch vehicle, the “Launcher Light” rocket.

The company is looking to grow significantly in the lead-up to the rocket’s 2024 launch date, and reportedly plans to more than double its number of employees by the end of this year.

As part of the announcement, Launcher also unveiled its new logo that is designed to symbolize the firm’s orbital rockets, high-performance engines, and the Earth.

Optimizing rocket engine performance with AM

Since its establishment in 2017, Launcher has continually leveraged 3D printing to upgrade the performance of its rocket engines. The company’s goal is to create efficient, optimal cost rockets capable of delivering small satellites to space.

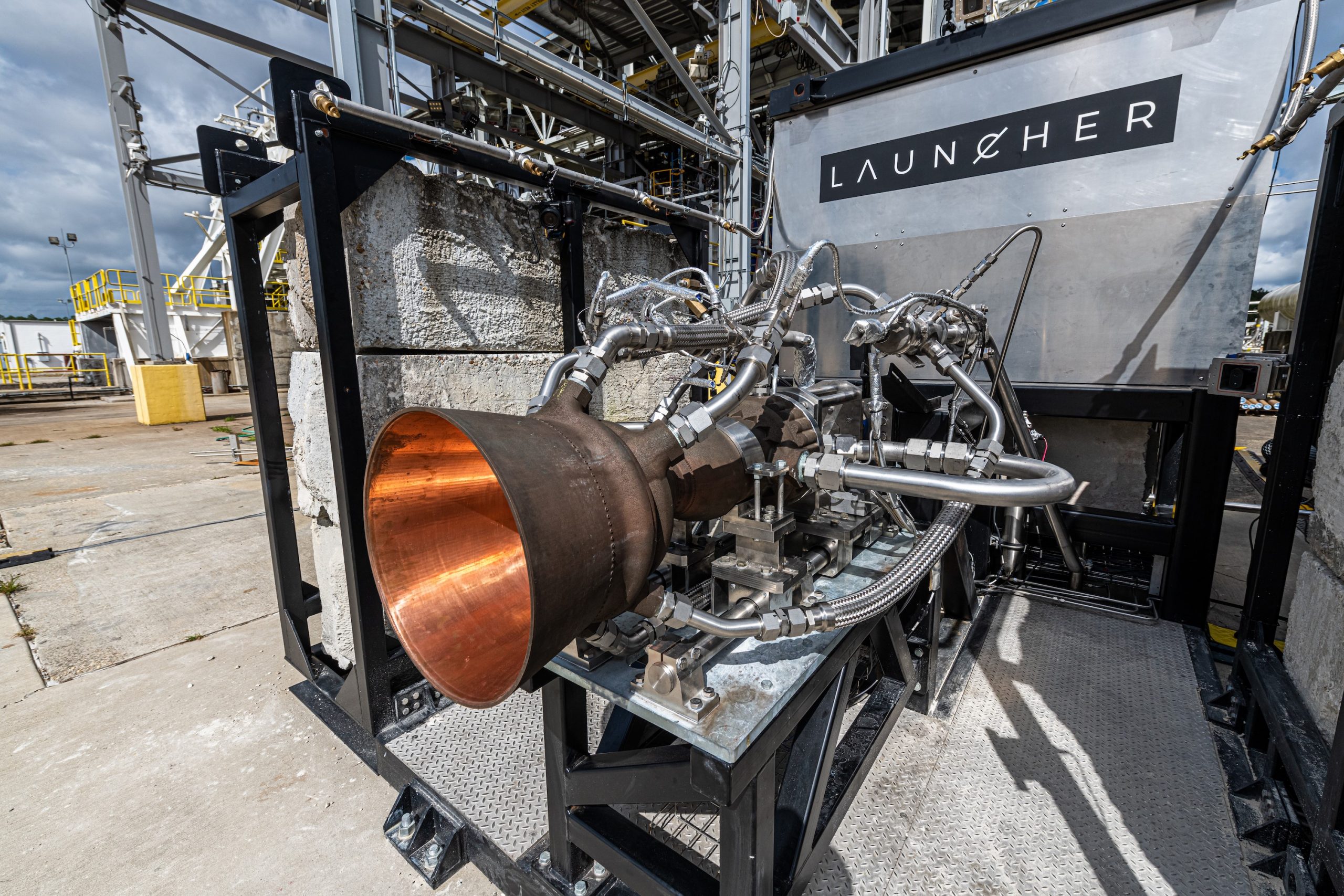

After being awarded a $1.5 million Space Force contract in 2019, the firm embarked upon developing 3D printed components for its E-2 engines, producing a rocket combustion chamber that was reportedly the largest part of its kind, measuring 860mm tall and featuring a 410mm exit nozzle. The combustion chamber was 3D printed in a single piece using an M 4K 3D printer provided by EOS subsidiary AMCM.

Launcher’s E-2 engines are 3D printed in high-performance copper alloy and purportedly require less propellant to get to orbit, in theory allowing the company to deliver more satellite cargo per rocket and subsequently offer a lower price than its competitors.

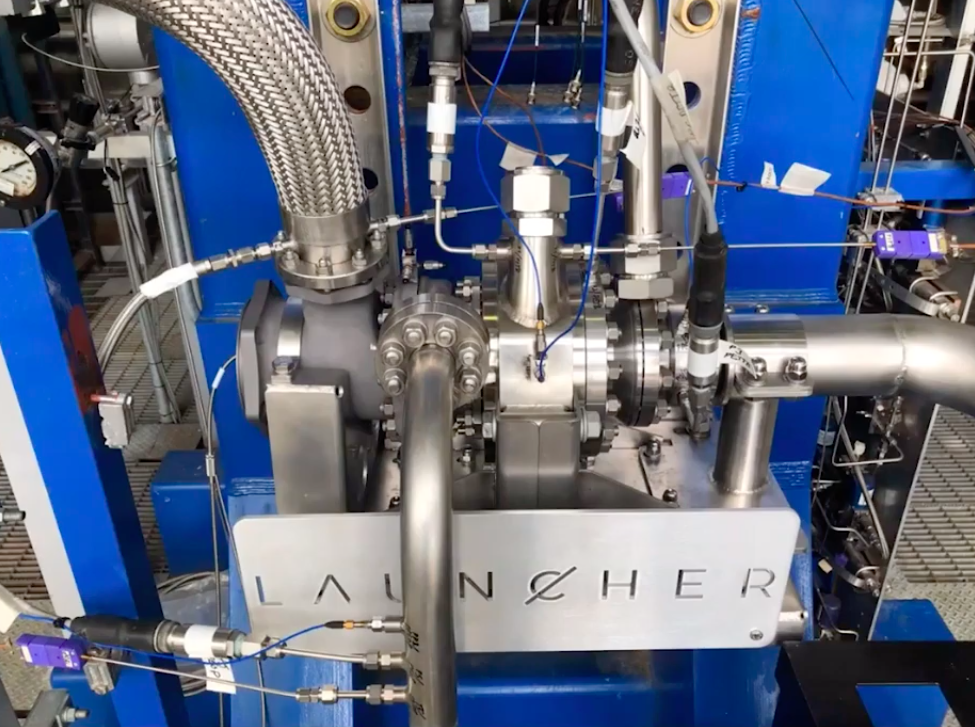

Just last month, Launcher teamed up with 3D printer manufacturer VELO3D and simulation software firm Ansys to optimize the design of another performance-critical component in its E-2 rocket engine, a heritage liquid oxygen (LOX) turbopump. Having undergone extensive engine tests at NASA’s Stennis Space Center, the turbopump will be integrated into the “Launcher Light” rocket prior to launch.

Accelerating rocket development

In its first few years, Launcher prided itself on being a lean company with few employees and low overhead costs, expending around $1.5 million per year.

However, in an interview with Ars Technica, Launcher founder Max Haot said the company will need to up this spending to some $10 million a year in order to reach orbit by 2024 with its “Launcher Light” rocket. He also revealed the company will need to scale up to around 150 employees by its first orbital flight, with plans to increase employee numbers from around 30 to 70 by the end of 2021.

Taking into account the $11.7 million Series A funding announced this week, Haot will attempt to achieve this scale up with a budget of $50 million and an additional round of funding expected to be completed by early 2022. As part of the Series A funding, Haot has invested $5 million of his own money from the sale of his Mevo camera business to software and peripheral manufacturer Logitech.

Launcher’s growth ambitions also saw the company move headquarters from New York to a 24,000 square foot facility in the aerospace hub of Hawthorne, California, earlier this year.

The race to space

The race to space is continually hotting up between private aerospace firms using 3D printing to develop rocket engines with enhanced in-flight capabilities, and this year alone has already seen several notable developments.

In February, British aerospace firm Orbex tasked AMCM with building the largest industrial 3D printer in Europe to enable the company to rapidly print rocket engines in-house. Once complete, the printer is expected to enable the printing of more than 35 large-scale rocket engine and main stage turbopump systems each year.

Orbex is looking to commence its first orbital launch in 2022 after receiving planning permission for its spaceport in the Scottish Highlands in August 2020, the first in the UK to be granted the permission.

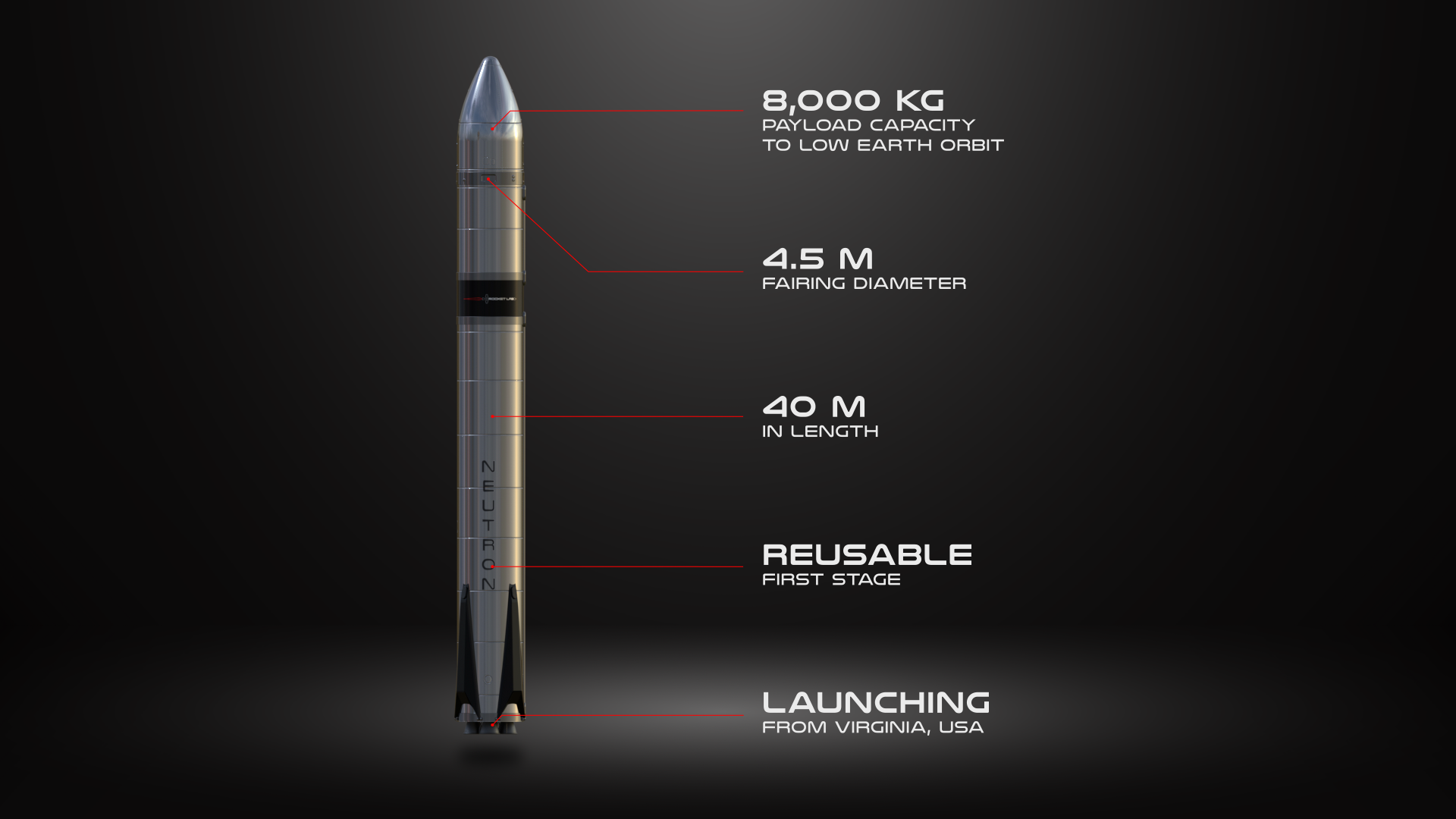

Meanwhile, in March California-based aerospace firm Rocket Lab announced plans to go public on the Nasdaq stock exchange in a move that saw the company valued at $4.1 billion. The company also lifted the lid on its newest innovation in development, the reusable Neutron launch vehicle, which will be equipped with an eight-ton payload and the capacity to lift more than 90 percent of all satellites forecast to launch through to the end of the decade, the company claims.

Elsewhere, NASA awarded a $3 million contract to 3D printed rocket manufacturer Relativity Space to launch small satellites into orbit, and US propulsion system manufacturer Aerojet Rocketdyne announced its upgraded RL10 rocket engine had successfully passed NASA hot-fire tests. The engine is equipped with a 3D printed injector and combustion chamber and will power the company’s Vulcan Centaur launch vehicle as part of upcoming exploratory space missions.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Launcher’s AMCM-3D printed combustion chamber. Photo via AMCM.