Researchers from Seoul National University of Science and Technology in Korea have published the schematics for an open source 3D bioprinter.

The authors of the paper explain that 3D printing, “is considered to be a major driving innovation in tissue engineering, since custom-made manufacturing for patients is essential for tissue and organ generation.”

3D bioprinters have been used to create human skin and also to develop a patch that may help treat heart disease in the future.

In the new research details are given for the, “design and integration of a multi-channel 3D bio-printing system at an affordable price based on open source hardware and software.”

The hardware and software components of the 3D bio-printing system and the process of finding optimal printing conditions are described in the paper. Fabrication of the hybrid scaffold of synthetic polymer and cell loaded hydrogel are presented to validate the performance of the system.

Reducing costs and advancing knowledge with open source hardware

Crediting the RepRap project as playing a significant role in the development of the 3D printing industry, the scientists describe four desirable materials properties for 3D bio-printing. These are viscosity, mechanical properties, biocompatibility and biodegradability.

The study was conducted with the aim of, “developing a low cost 3D bio-printing system with pneumatic and piston extrusion and needle valve jet methods.”

The resulting 3D bio-printer consists of, “positioning stages, biomaterial dispensers and a control system.” The researchers note that by making use of open-source hardware and software costs of production were reduced.

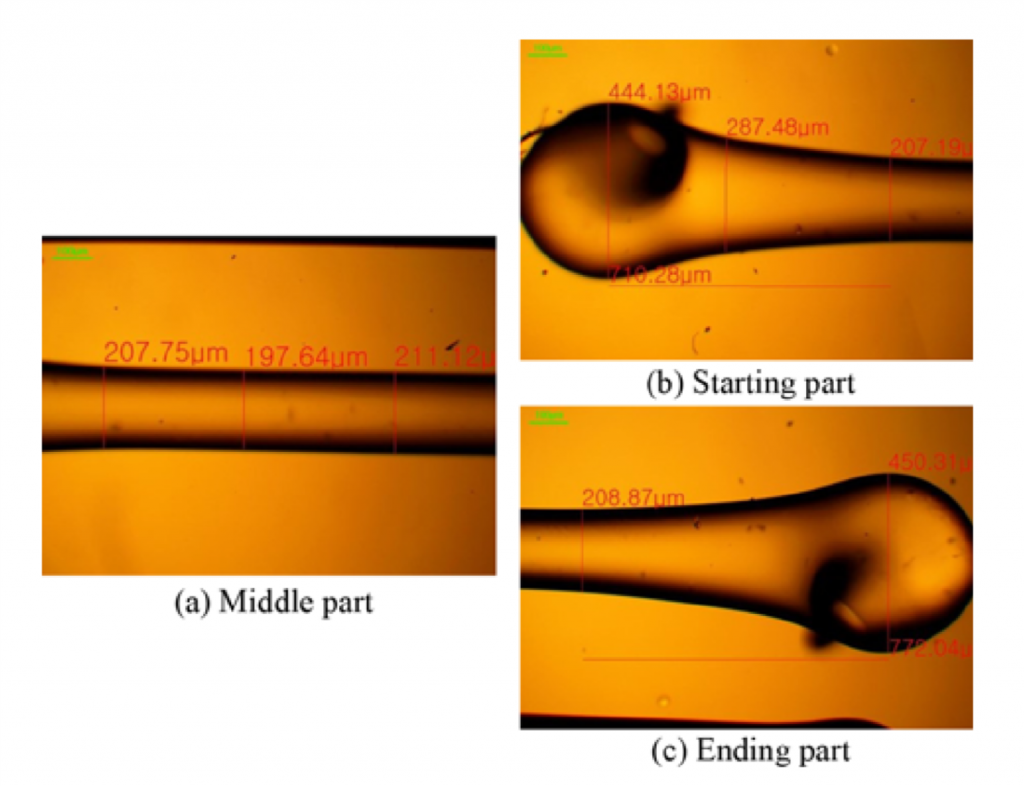

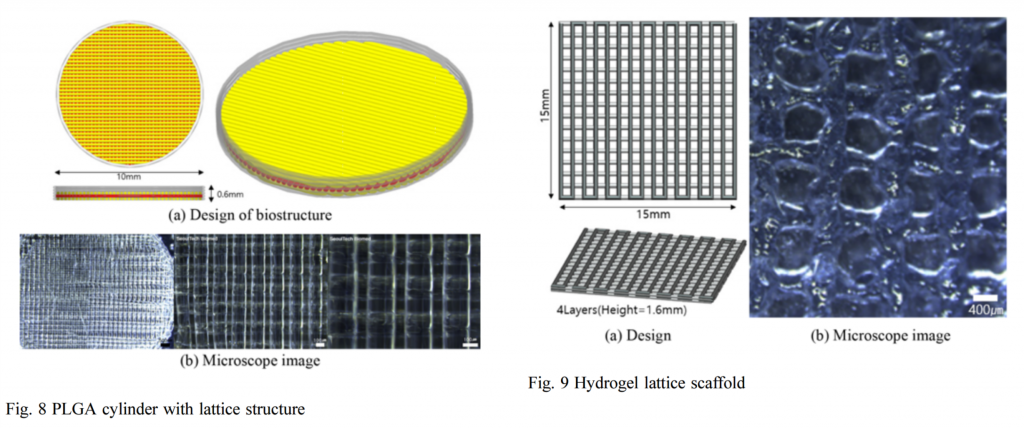

In 3D bioprinting a scaffold can be made of biocompatible and biodegradable materials. Frequently poly(lactic–co-glycolic acid) (PLGA) is used as scaffold material. Experiments to determine the optimum conditions for printing PLGA were conducted and 3D biostructures with multi-materials as well as single materials were fabricated.

Among the successful 3D prints, the researchers made a cylinder with lattice structure, a hydrogel lattice, a scaffold with 2 materials and a 3D cylinder scaffold of PLGA and cell laden hydrogel.

The authors of the research are Jaehoo Lee, Kyu Eon Kim, Sumi Bang, Insup Noh and Chibum Lee.

The paper, A Desktop Multi-Material 3D Bio-Printing System with Open-Source Hardware and Software, is published in the April edition of the International Journal of Precision Engineering and Manufacturing and available online here.

For all the latest 3D printing news, subscribe to our free newsletter here and follow our active social media accounts.

Also, don’t forget that 3D Printing Industry readers can vote now in the 1st Annual 3D Printing Industry Awards.

Featured image shows the Schematics of the 3D bioprinting system. Image by Korean Society for Precision Engineering and Springer-Verlag Berlin Heidelberg.