From a 3D printing perspective, this year was an interesting one for me, in that we now have in-yhghouse 3D printing. The U Print has been chugging away in the corner of the office producing our latest and greatest design iterations, which has seen the rest of the office slowly filling up with ABS+ parts of varying shapes and sizes. As a result of this in house capability, I have, if I am totally honest, lost some interest in the day to day shenanigans of the 3D printing industry as running a machine tends to demonstrate just how truly ridiculous this industry has become. Yet, if you look beyond the hype, 2014 has certainly seen some significant changes and genuine innovations too. So without further ado, in reverse order, these are my Top 5 stories from 2014:

5. Whatever happened to….all those machines announced at CES in January? Yes, 3D Systems, I am talking to you. Avi was there in Vegas, the lights were shining, and all in the 3D printing world was shiny and new. We were promised new $5000 colour machines, and Ceramic machines and food machines. I had intended to buy all three so I could print all my own Christmas presents this year. My loved ones would have revelled in powdery mini me figurines, while munching on 3D printed sugar delicacies and finally sipping some mulled wine from my own specially created 3D printed cups. Alas, it was not to be, and these mystical machines are still to be commercially released. Maybe next year.

4. Whatever happened to…the Bot? After all the hype, the claims of careful marketing strategies, the online abuse (I received for daring to question the claims) and the drip fed videos, BotObjects’ marketing seems to have gone quiet. Are they still around? I do not know and I do not care. Maybe when they saw the 3D Systems colour machines at CES they retreated to their Bot Cave?

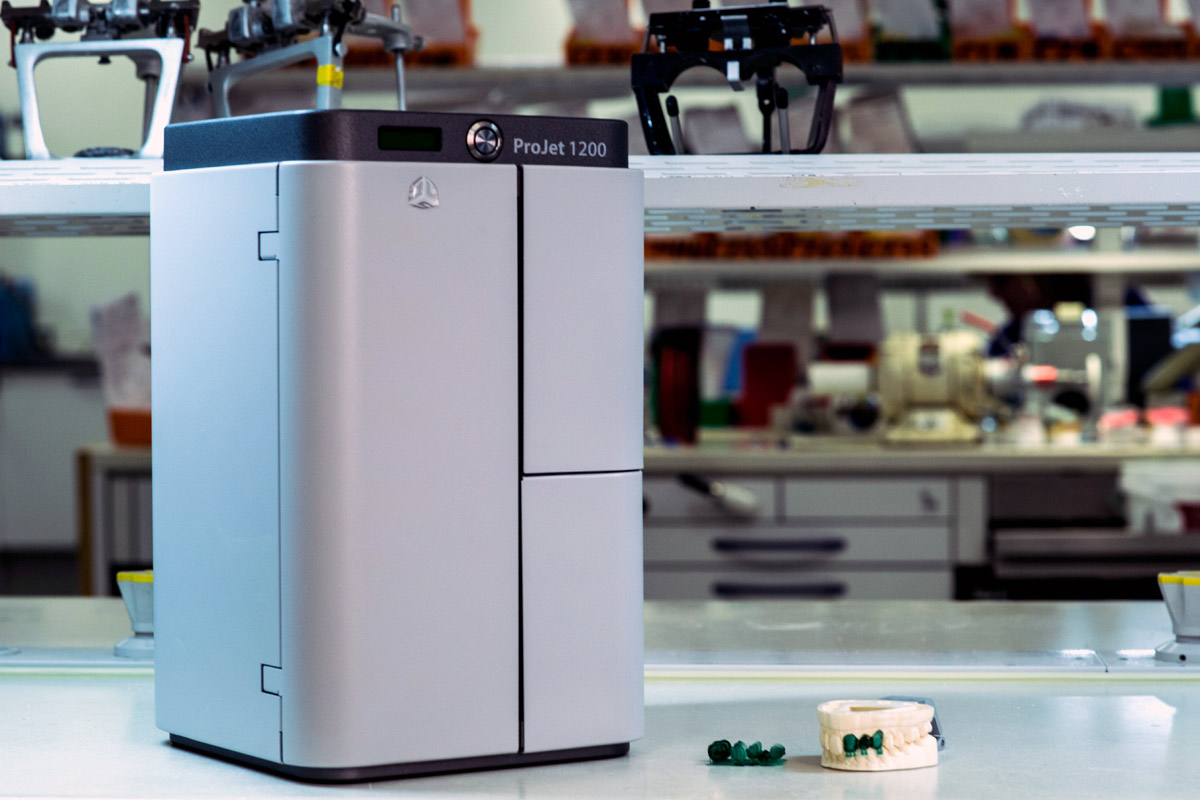

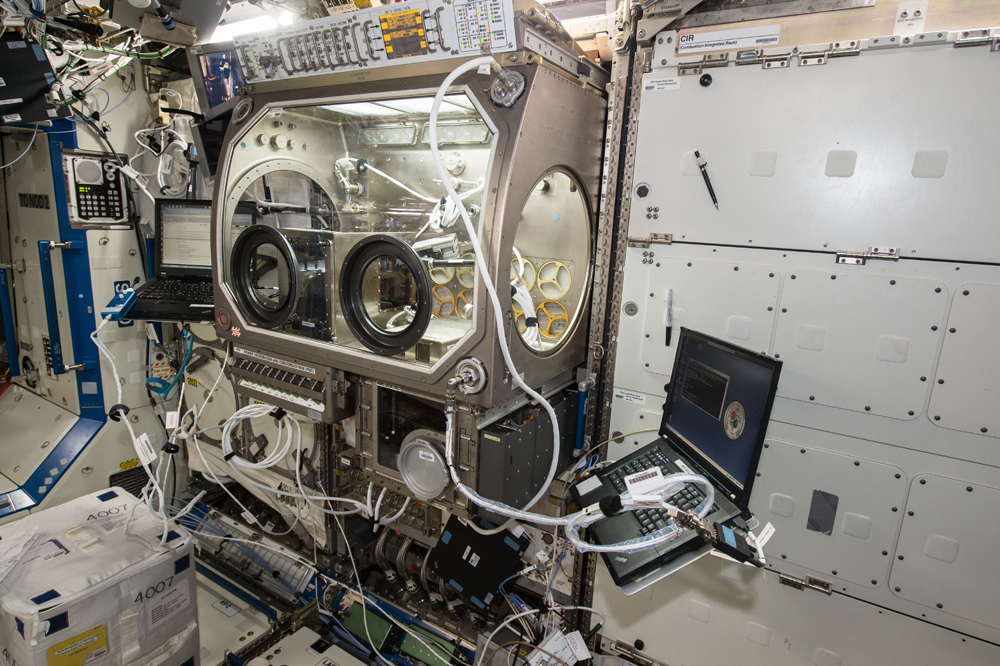

3. Interstellar Hype…Made In Space meets Neri Oxman. Towards the end of the year we had one genuine 3D printing story and one that was, well, ridiculous beyond belief. Recently we had the first ever off-world manufactured parts via the Made In Space programme operating on the International Space Station. This in itself generated copious amounts of PR and hype, following on as it did from the film Interstellar (which was very good – go and see it). We had the mainstream media sucking it all up saying “now we can make our spacecraft in space.”

I can see that this is a start and, as such, an important step but let’s be honest here —parts currently made in space are still little bits of plastic with limited uses. I am just thankful the first off world part was not a twirly vase.

Around the same time, Stratasys (never one to miss a trick) announced its annual “let’s see what Neri can do with a Connex” art show. This year it was (surprise, surprise) space related, with a future organic space suit thingy that looked more someone had run amok in the paint section of B+Q with brocolli and cauliflower. Frankly this is getting embarrassing. Stratasys make these great machines yet we are all starting to associate them with nonsense PR pseudo science. As I said, stick it in the Tate Modern, call it art, and that is fine. Just don’t dress it up as science.

Joint 1st. I couldn’t decide which to make 1 or 2 so I will cheat and award a joint number 1 to HP and Picsima.

HP, as anyone following this sector will know, made a big announcement this year, that sparked off lots of “we are not worried” PR from everyone else. Oh yes? Then Autodesk at the recent Autodesk University announced HP is using its open source Spark platform with this new HP system. 2016 is going to be a very interesting year! I have made my views on this clear enough – I think this is a big issue for the industry. Possibly the biggest, if the machine does everything it claims to (which it seems to). You can say what you like, but HP make good pro level hardware, and make no mistake this will be pro level hardware. None of this consumer 3D printing rubbish for HP. I mean, I have an A1 HP plotter in my office, currently 5 years old, still going strong, which is more than can be said about some of the hardware I use! Ask yourself this. If I were a bureau, in the market for buying a £100k machine, knowing the HP machine was coming, would I buy or lease anything else right now (unless it was replacing an existing system at end of lease)? That is the issue Stratasys and 3D Systems is facing for the next 12 months. I know what my answer would be. I predict 2015 will see a drip feed of HP PR based around “look what’s coming folks!”

One final thought on HP that I haven’t seen anyone mention yet is the link between faster printing and materials. If they can print (part for part) 10x faster, that directly translates to 10x more revenue for HP on material sales. Think about that for a minute.

My other Joint number 1 is at the other end of the scale but in its own way I believe it is just as disruptive for certain markets. Earlier this year I visited Fripp Design in Sheffield to see its mysterious Picsima 3D printer prototype. I have signed an NDA so my lips are sealed, but let me just say this is a fantastic machine that prints real silicone parts. Not some costly blend of resins in a £250k Connex that has all the structural integrity of a jelly baby, but the real genuine silicone. Suffice to say, the implications of this in certain sectors is huge. Medical parts in real materials, custom seals, sports…you name it. Fripp is looking for investment to take this to the next level. If you have a spare £200k call them…then remember I told you when HP, Stratasys or 3D Systems buys them out for (hundreds of) millions. I’ll happily take a finder’s fee of 1%.

So that’s all folks. 2014, another year of 3D printing nonsense mixed with some genuine stuff. Who knows what 2015 will bring. Rachel hinted at stuff that will impress me come the spring, but right at this time I’m happy with my U Print and its 0.254mm layers and £150 ABS+ materials, because the reality is — that works for me. Therein lies the problem for the industry, and why HP has it right. Focus on the bureau market and sod the consumers.

You heard it here first.

To all, have a restful Christmas and a Happy New Year! Then get ready for the onslaught of 3D printing hype from Las Vegas in January!