Josef Prusa, has introduced the resin-based Prusa SL1 – an open source SLA 3D printer. Prusa is the founder and CEO of Prusa Research, which manufactures open-source 3D printers.

Earlier this year, Prusa acquired Futur3D, a Czech company specialising in resin printing, and expanded its team to 320 people. It now aims to develop open-source resin based 3D printers starting with SL1 – this will add to the FDM/FFF range of systems already available.

FFF/FDM technology is based on forcing out molten thermoplastic material (filaments). Whereas, SLA is based on transforming liquid materials to solid parts, layer by layer, by curing them by using a light source in a process known as photopolymerization.

Josef Prusa wrote on company’s blog,

“The SL1 isn’t trying to compete with the flimsy Photon or with the ultra-pricey Form but instead I want it to be the MK3 of the resin world – have the best print quality, convenient design and features, ease of use and other things, while keep a price accessible for an everyday hobby maker.”

SLA technology

The three main types of SLA processes are, Laser-based (laser SLA), Digital-light processing (DLP-SLA) and Masked (MSLA).

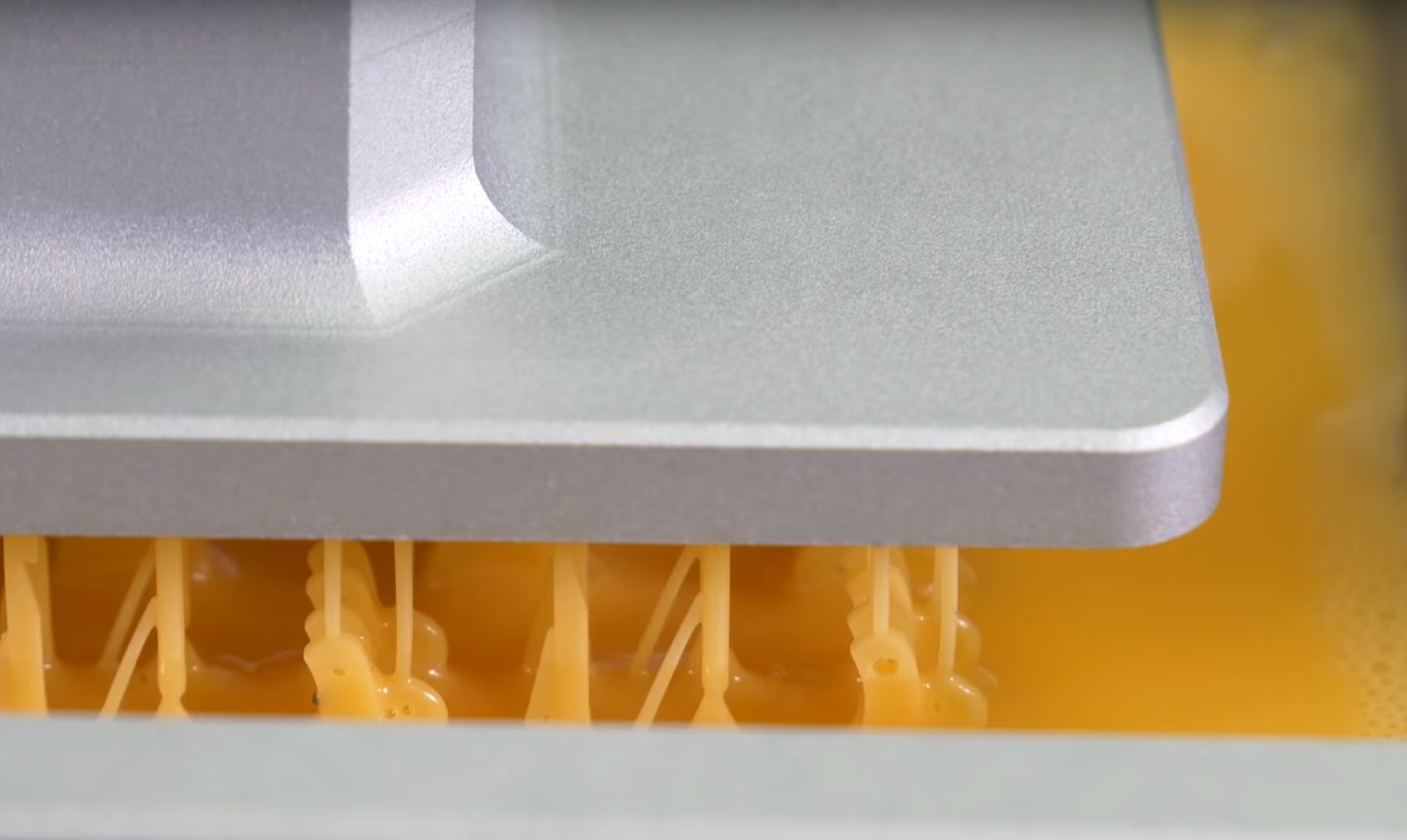

In all of these processes, a container of photo-reactive liquid resin is exposed to light to create thin solid layers that eventually form a solid object. The Prusa SL1 uses MSLA, with an LED array as a light source in sequence with a LCD photomask to form the light image.

Similar to DLP printers, the LCD photomask is composed of square pixels. The pixel size differs depending on the formation of the LCD photomask and each pixel is deactivated on the LCD to let the LED light pass through and shape the resulting layer. Hence, the XY accuracy is fixed and is independent of how you can scale the lens, in theory meaning MSLA can operate with better accuracy.

In simpler terms, the LCD projects layers as transparent images, while remnant of the image is black, allowing the light to pass only via the transparent layer shape.

Prusa SL1 Tech Specs

The SL1 has a 5.5’’ high-resolution LCD display with the physical resolution of 2560×1440p, developing 0.047 mm per pixel, and a fixed XY resolution. A high-performance UV light cures one layer individually in about 6 seconds and then the printing platform is raised, so the printer can begin forming another layer. This configuration provides a maximum print area size of 120 × 68 × 150 mm (or 4.7 × 2.6 × 5.9 in.).

The printer’s core is a rigid frame with a separate body, which improves stability and reliability. This allows the SL1 reaching a layer height of 0.01 mm. Although, users are recommended to stay within the range of 0.025 – 0.1 mm per layer. The printer has the option of variable layer high and is open to third-part resins.

Tilt bed and resin level sensor

One feature of the SL1 is a unique resin level sensor located in the resin bed (aka ‘tank’). It allows you to pour the required amount of polymer into the tank and informs when the resin is running low and requires a refill.

The sensor is intended to prevent a user from running out of resin mid-print.

There’s also a removable tank with a flexible transparent FEP film on the base. Underneath, there’s a LCD display and the UV light. The printer also features a motorised tilt function in the resin tank, allowing the printer to be not lifted vertically from the bottom of the tank after curing a single layer.

By tilting the tank, the resin is also stirred – which is intended to improve print quality. Prusa also claims that faster printing is possible. Prusa writes,

“FEP material is cheap and we will have spare parts available through our e-shop. In case you scratch or damage the FEP film in any way, the replacement is actually pretty easy – just unscrew a couple of screws, remove the damaged film and insert a new one. It will automatically stretch as you tighten the screws again. To compare, Form 2 is using resin tanks with silicone instead of FEP and even the resin tank for “high volume” printing “may last 2 liters+” at a price of $99. You have to bin the whole tank after it stops working.”

For more news related to 3D printing and open-source, subscribe to our 3D printing newsletter, or join us on Facebook and Twitter.

If you are looking for a new career, visit 3D Printing Jobs.

Featured image show the Original Prusa SL1 – open source SLA 3D printer. Image via Prusa.