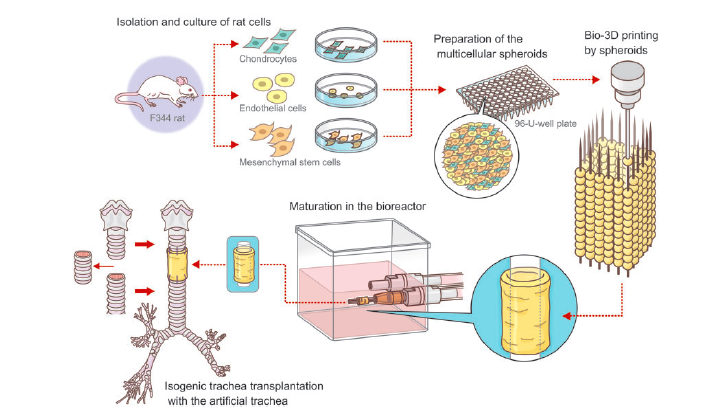

Researchers from Nagasaki University and Saga University in Japan have successfully 3D printed artificial tracheas without using scaffolds, and surgically transplanted them into rats.

A Regenova bioprinter from Cyfuse Biomedical K.K.was used to generate spheroids consisting of several types of cells. These were then used to generate a 3D tubular trachea structure. After printing, the artificial trachea was first matured inside a bioreactor and then transplanted into the rats.

The problem with scaffolds

Currently, the vast majority of artificial tracheas require scaffolds to maintain airway strength, stiffness and to guarantee a continuous blood supply.

Scaffolded artificial tracheas, however, carry a risk of infection, irritation, reduced biocompatibility and degradation over time.

To develop cells for a scaffold-free way of 3D printing, the researchers took chondrocytes (embedded in bone cartilage) and mesenchymal stem cells (found in skeletal tissue) from F344 rats and combined them with rat microvessel endothelial cells.

Combining and 3D printing the tissue

The cells were cultured at body temperature in 150-mm tissue culture dishes. After culturing, the cells were then put into U-well dishes, forming into cell spheroids, which could then be 3D printed.

The Regenova 3D printer used in the experiment has previously been deployed in the 3D printing of nerve tissue, liver sections, and liver bud implants.

The Regenova 3D printer placed spheroids in a 9 by 9 needle array in what can be described as “the Kenzan method.” Overall, 384 spheroids generated the 3D tubular trachea structure. The printed spheroids were then covered in with chondrocyte growth medium and endothelial cell growths prior to transplantation.

Testing and transplanting the trachea

The tensile strength of three of the 3D printed artificial tracheas was tested to failure using a DMT Tissue Puller. The test showed that the tracheas were strong enough to transplant into nine F344 rats.

The tracheas were surgically placed into the rats together with stents. The F344 rats were subsequent carefully monitored over 23 days and their activity noted.

According to the paper’s conclusions, the technology demonstrated the possibility of 3D printing further tracheal grafts, for use in trachea regeneration.

The full paper, entitled “Scaffold-free trachea regeneration by tissue engineering with bio-3D printing” by Daisuke Taniguchi, Keitaro Matsumoto, Tomoshi Tsuchiya, Ryusuke Machino, Yosuke Takeoka, Abdelmotagaly Elgalad, Kiyofumi Gunge, Katsunori Takagi, Yasuaki Taura, Go Hatachi, Naoto Matsuo, Naoya Yamasaki, Koichi Nakayama and Takeshi Nagayasu, is available to read online.

Make your nominations for the 3D Printing Industry Awards 2018 now.

For more stories on bioprinting, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows a Regenova 3D printer on display at Indiana University Medical school.