Josh Coray’s obsession with paintball started at age 17 in a paintball contest that lasted nearly two days. “My friends had a few paintball guns, and I borrowed a really bad one with a mask that fogged up and barely fit. We played on 40 acres. It was a crazy huge place to go play—we had a blast! After that, I knew I was going to design paintball equipment someday.”

By day, Coray is an accomplished senior designer. At night, Coray is a husband, father of five, and Lead Designer for J4 Paintball. He has always had a knack for design. “I have experimented with design since I was a kid. I saw computer-aided design (CAD) on TV one day and said to myself, ‘I want to do that.’ So I took drafting in high school and then in college.”

To build his dream paintball equipment, Coray started out by tapping into his worldwide network of contacts that he developed over the years through online paintball/techie forums. “I have people on both coasts that can help me build stuff; I also have people in Arizona, Chicago, and even in the UK and Asia.” He organized his resources—everyone passionate about paintball—into a company now called J4 Paintball.

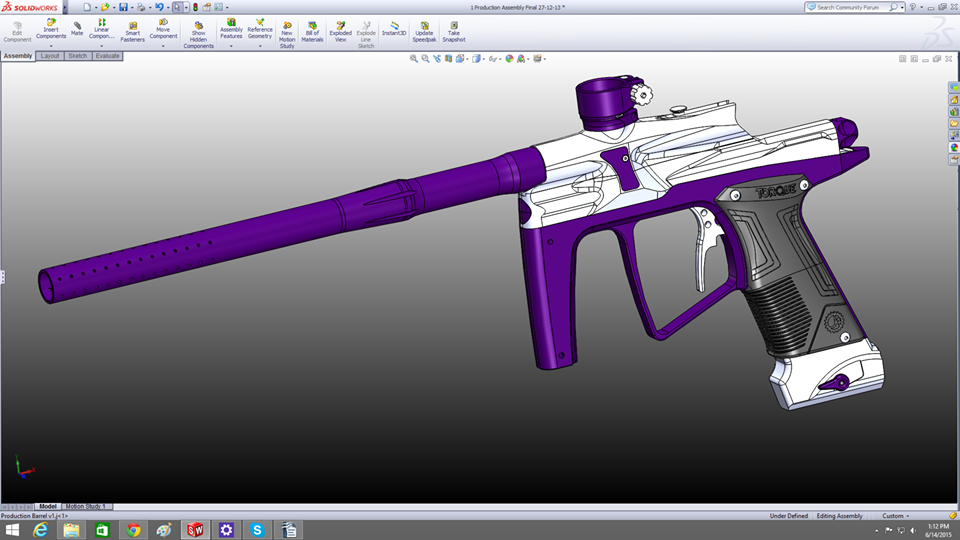

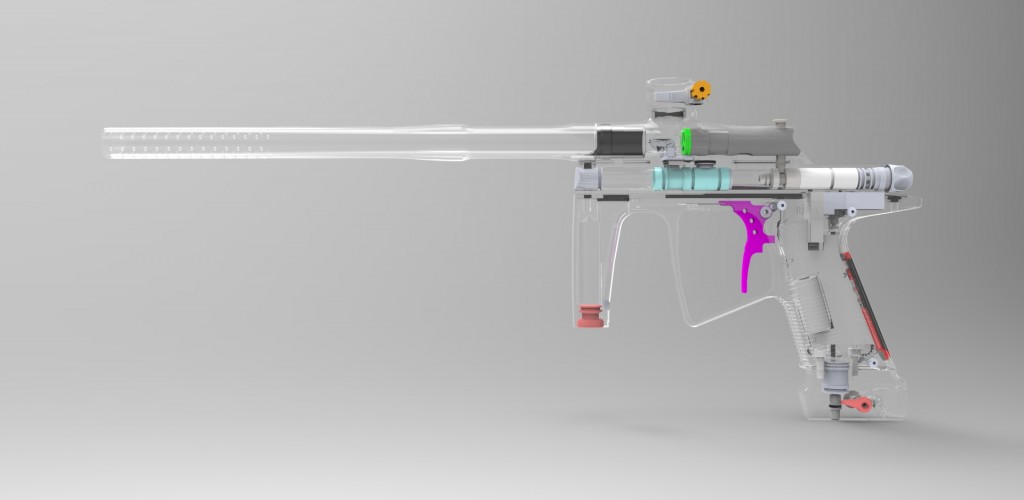

Coray eventually started doing most of the design himself using SOLIDWORKS, which allowed him complete control of delivery turnaround times. “SOLIDWORKS is such a well-known platform that I can send CAD files to a machinist who can directly import the files into his CAM software for machining. It makes working together a breeze.”

He also leverages Stratasys 3D printing for instantaneous testing of fit, function, and form. J4 Paintball can go from CAD, to 3D printing, to part, to testing sometimes within five or ten minutes. “That’s probably the most amazing thing: the technology tools enable me to make these components in a matter of minutes without having to send them out to somebody else. I essentially print the parts, stick them in, and test them. Then, boom, take pictures or video and show my customers right on-the-spot with Facebook. That’s just unheard of in traditional product development models.”

GoEngineer, a reseller in Texas, provides sales and support to J4 Paintball for both SOLIDWORKS and Stratasys products. “GoEngineer has webinars to help me utilize my tools to the max. It’s great because all this information is pushed to me; I don’t even have to leave my desktop to become more knowledgeable in CAD design and 3D printing.”

Coray continues: “3D printing helps me, along with SOLIDWORKS, to make my designs as light as possible. I can do a mass analysis with SOLIDWORKS and then 3D print my designs until I have the perfect part, which means it’s both lightweight and comfortable—before the customer ever touches it. Our guns are, overall, some of the lightest on the market.”

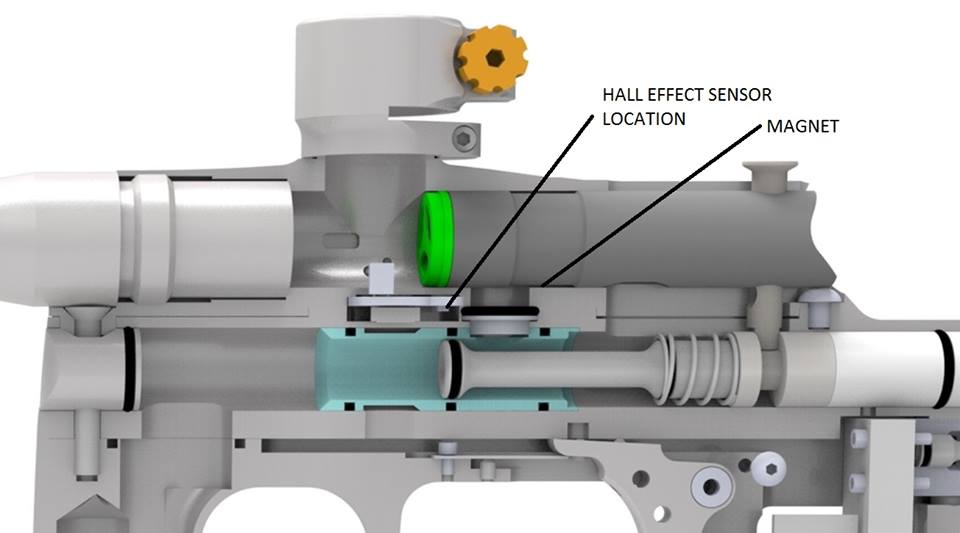

Traditional product development cycles often require many months—even years—to produce new products. Because J4 Paintball has maximized technology and communications, the company can be in production in a matter of weeks. “We are in a different economy now because of the Internet,” says Coray. “We are currently doing a crowd-funding campaign for a new paintball gun that is the first ‘Stacked Tube Spool’ valve gun, a brand new platform for paintball. It also features a completely mechanical timing system, which is what allows it to be run mechanically—some real firsts in the industry!”

It helps to have a faithful following on Facebook, which J4 Paintball leverages for their customer’s benefit. “We show customers how to fix their guns with short videos,” says Coray. “It’s way better than a manual, costs us next to nothing, and our customers think videos are easier to use than reading about how to fix something.”

Another benefit of Facebook is customer feedback—on a regular basis. “I like to show off new designs on FaceBook, and, sometimes, people don’t like what they see,” says Coray. “In one case, we redesigned a paintball gun the same week we got feedback and made it the next.”

Coray looks forward to an even brighter future for J4 Paintball and the US economy. “We’re in kind of an economic reboot. Companies like Etsy and others are helping to get smaller end producers to market. You’re going to see a lot faster response to market needs, and you’re going to see a lot more creative products out there. Millennials are all over this kind of thing. The shift is happening right now, and I am ready for the ride!”