Advanced and additive manufacturing service bureau Ivaldi Group has partnered with Wilhelmsen, the largest maritime network in the world. Operating from a new additive manufacturing facility in Singapore, Ivaldi will provide Wilhelmsen with on-demand spare part production for ships and other maritime equipment, potentially servicing upwards of 100 vessels per day.

Speaking with Espen Sivertsen, CEO of Ivaldi Group, 3D Printing Industry learned more about the company’s latest move, and the apparent rise of additive manufacturing in maritime.

A maritime standard for 3D printing bureaus

Ivaldi Group, headquartered in San Leandro California, was co-founded in 2016 by Norselab, a Norwegian accelerator. Since then, Siversten tells me, the company has been channeling the backwaters of the additive manufacturing industry and exploring its supply chain-changing potential with a number of select industry partners.

In December 2017, Ivaldi was credited as a participant in DNV GL’s first classification guideline for additive manufacturing in the maritime and oil & gas industries. In turn, Ivaldi is working to provide the quality control standard for maritime 3D printing bureaus.

Why maritime?

In comparison with early adopters like aerospace and automotive, the maritime industry is a relative newcomer to additive manufacturing. As Siversten points out, “In industries like aerospace, the price doesn’t matter, and [maritime is] one of the spaces that not a lot of people are paying attention to.”

“What matters in maritime is the sheer volume and no one else is really looking at it.”

In 2016 the National Institute for Shipping and Shipbuilding (NISS) in the Netherlands released its blueprint for 3D printing in the industry over the next 30+ years. Since then, maritime has seen a rise in the number of 3D printing related applications. Closely related to welding, wire-arc additive manufacturing (also known as WAAM) has proved especially popular in the sector. Furthermore, leading global marine and offshore engineering group Sembcorp Marine is one of a handful of industry stakeholders adding 3D printing to its digital initiative.

As Geert Schouten, director of Shipbuilder and one of the contributors to the NISSS blueprint, said, “The first digital ship builders will conquer the maritime world quicker than people think. They will leverage digitalization, robotization and 3D printing successfully.”

By specializing in a maritime 3D printing service in partnership with Wilhelmsen, Ivaldi then seems positioned to become one of the front runners in this industry’s growing demand.

Cutting the cost of inventory

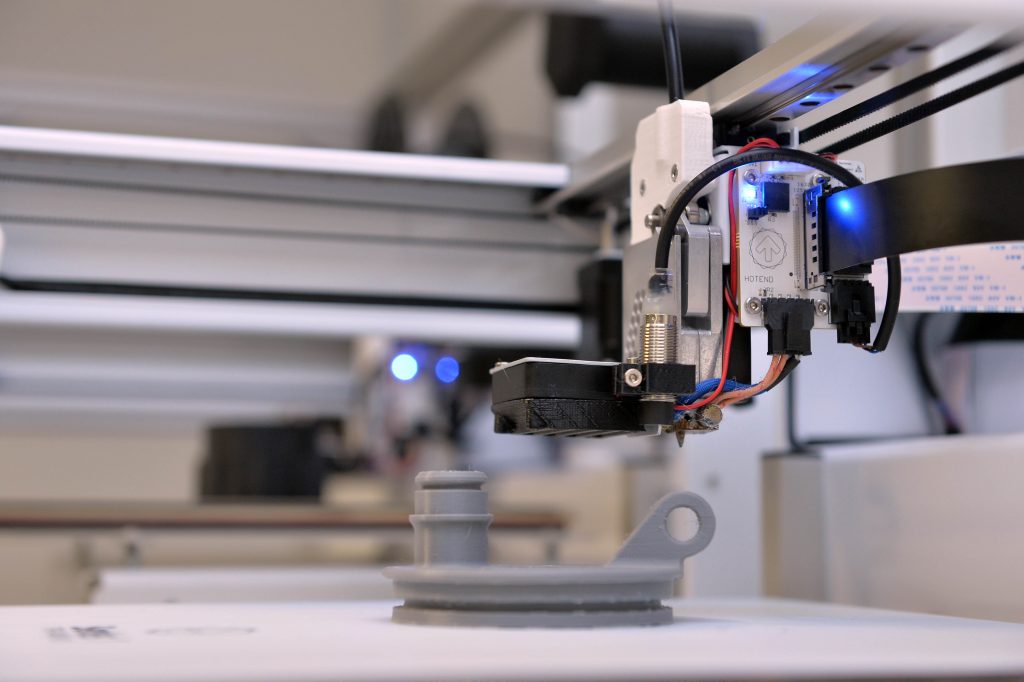

Though essentially a technology agnostic service, Ivaldi Group is starting its on demand production service with desktop 3D printing for spare parts. This will focus on maritime’s “unobtainables” i.e. parts that are no longer available to buy from the manufacturer, and non-critical components, such as plastic handles, bolts and gaskets.

As seen in similar case studies from the U.S. Marine, such production has the potential to save the industry thousands of dollars as the alternative for, say a broken door handle, would be to buy a whole new door.

As an example case study, Sivertsen explains, “instead of having to buy a new welding mask because of a broken clip, a new clip was printed for one-tenth of the price. It was also delivered within 24 hours as opposed to having to wait the 3-4 weeks it would otherwise take to ship to the customer.”

Kjell Andre Engen, Executive Vice President of Marine Products at Wilhelmsen Ships Service, the home of the new facility in Singapore, comments, “Looking at the costs associated with our marine products sales, the supply chain costs are frequently at least as large as the Cost of Goods Sold,”

“Additive manufacturing with a technology partner like Ivaldi will enable us to reduce costs and environmental footprint while also increasing our service capabilities to serve our customers.”

Aligning end users and OEMs

Ivaldi’s service is offered on a subscription basis, a move that reduces the cost of potential overheads for physical warehousing. With three strategically placed production centers already, in Norway, Mexico and now Singapore, Ivaldi is also building its global network to reduce delivery pressures and save on ship downtime.

Capt. J. N. Patwardhan, General Manager for Wilhelmsen Ship Management Singapore, said, “As we could possibly get quality parts on demand at a relatively lower overall cost, we are willing to subscribe,”

“Considering our present day spend and lead time on ship spares, additive manufacturing will help us better manage inventories and predict deliveries, thereby reducing operating costs.”

As it begins to build its network, Ivaldi is looking to get OEMs involved is its service, offering them royalties and valuable access to this growing industry. As Siversten says, “We want to align the interests of end users and OEMs.”

For more on this project and more of the latest additive manufacturing news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

For careers, visit 3D Printing Jobs to post and search new opportunists in engineering, academia, marketing, sales and management.

Featured image shows a Wilhelmsen logistics carrier ship. Photo by Bahnfrend/CC