Additive manufacturing technology developer ioTech Group has debuted its new Continuous Laser Assisted Deposition (CLAD) 3D printing technology.

Designed specifically for electronics applications, the CLAD process is a unique multi-material 3D printing technique that’s been in development since early 2016. According to ioTech, the company’s upcoming 3D printer will be able to process almost any flowable industry-certified material with high precision and high speed. The system will give manufacturers the ability to achieve drop-by-drop material deposition while enabling ‘unmatched production yields’ in electronics manufacturing.

“We are excited to introduce our unique C.L.A.D. technology to the electronics industry and additive manufacturing,” states Dr Michael Zenou, ioTech’s co-founder and CTO. “Its ability to deposit any flowable industrial material for so many applications is unprecedented. It will increase production efficiency and encourage innovation for many companies.”

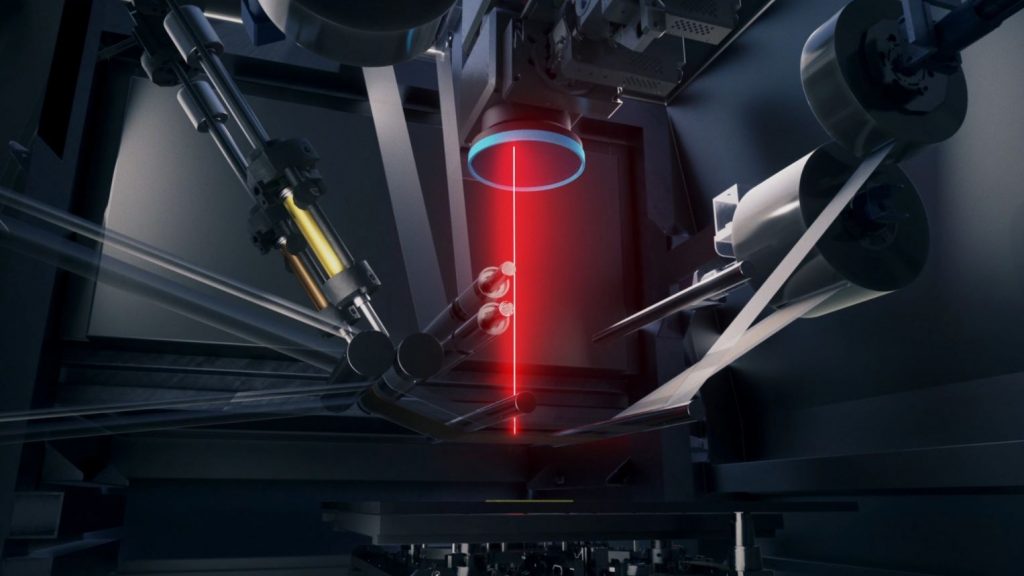

How does CLAD 3D printing work?

Based in the UK, ioTech conducted most of its R&D in Israel. The company’s proprietary CLAD 3D printer has reportedly been engineered to be both simple and robust, and will require minimal maintenance. Described as an eco-friendly alternative to traditional manufacturing, CLAD can process up to six flowable materials at the same time.

The process itself comprises three different steps, starting with a material micro-coating phase which will coat a foil with the desired feedstock material. Then, a pulse laser will be used to jet the material from the foil onto a substrate below. Finally, the 3D printed part will go through a multi-functional inline post-processing step to prepare it for end-use.

According to the firm, the coating and jetting steps will offer resolutions of up to 20 microns and will feature closed-loop monitoring. On the other hand, the integrated inline post-processing will include UV and thermal curing, as well as laser sintering and ablation.

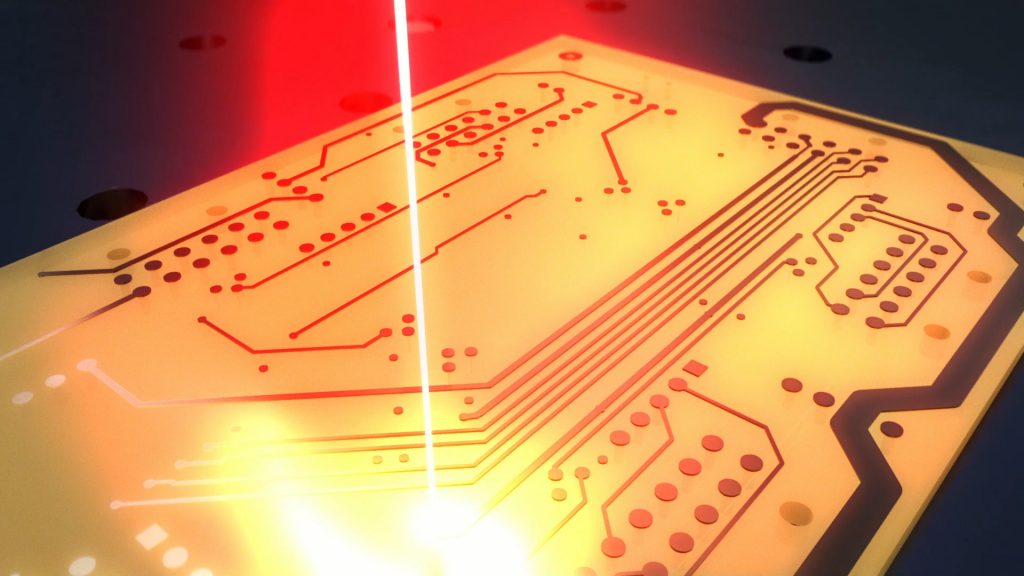

Owing to its incredible material capabilities, users of the CLAD process will be able to work with acrylate, epoxy, silicone, metal pastes, ceramic pastes, carbon pastes, and much more. The list of potential applications is also extensive, and includes semiconductor packaging, printed circuit boards (PCBs), adhesives dispensing, multi-layer wire bonding, gaskets, and sealing.

Zenou adds, “A whole host of industries will be able to adopt an agile manufacturing approach to deliver fully functional products fast, facilitating mass customization when required, and at the same time, be eco-friendly. The flexibility of C.L.A.D. is simply remarkable.”

Investments from ASM Pacific Technologies and Henkel

In line with the announcement, ioTech has also received two new investments from ASM Pacific Technology (ASMPT), a supplier of hardware and software for the semiconductor sector, and Henkel Adhesive Technologies, an adhesive materials specialist. ASMPT was an early investor in the company and has doubled down, while Henkel is a new entry.

Working with both companies, ioTech has already identified several new applications of its 3D printing technology in electronics manufacturing. Henkel, in particular, believes CLAD will complement its existing portfolio of adhesives, functional coatings, and sealants excellently.

“ioTech is thrilled to receive ASMPT and Henkel’s vote of confidence,” concludes Hervé Javice, ioTech’s co-founder and CEO. “These investments are a validation of our disruptive technology. ioTech’s unique system will add significant value for electronics manufacturers in terms of innovative designs and higher yields. We look forward to a successful and fruitful collaboration with both ASMPT and Henkel.”

The market for 3D printed electronics is a niche but growing one, with several manufacturers now looking to make a name for themselves. Among the most developed is 3D printer OEM Nano Dimension, a company which is known for its flagship DragonFly LDM 3D printer. Optomec also recently released its own electronics 3D printer, the Aerosol Jet HD2, capable of fabricating circuit boards for signal relaying and automotive radar applications.

In the defense sector, the U.S. Air Force contracted circuit board fabrication specialist BotFactory to develop a fully-automated electronics 3D printer back in March. The desktop system will be capable of 3D printing and assembling PCBs on-site and on-demand.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a rendering of the CLAD 3D printing process. Image via ioTech.