Investment in the 3D printing industry is picking up again after the summer break. In this round-up of recent additive manufacturing business and investment news we look at fund raising plans for several 3D bioprinting ventures, investment in high-tech centers across the world and increasing collaboration designed to bring additive manufacturing to end use production.

New high tech demonstration centers

In Hyberbad, India SLM Solutions and the International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI) – an organisation reporting to the country’s Ministry of Science and Technology – have opened a technology demonstration centre for additive manufacturing. The project is intended to show the industrial sector the advantages of industrial additive manufacturing.

Trumpf has opened a €26M smart factory in Chicago. The 50,000 square feet facility cost €13 million to build and contains €13 million in equipment. Nicola Leibinger-Kammüller, Chief Executive Officer of the Trumpf Group told guests at the opening event, “in Chicago, we can present our vision for connected production to our customers in the Midwest practically at their doorstep – and work with them to drive forward connected production in the Industry 4.0 era”.

Trumpf currently offers the TruPrint 3000 and TruPrint 5000 as additive manufacturing solutions and will introduce new TruPrint 3D printing platform, TruPrint 1000 later this month at the TCT show in Birmingham, UK.

3D bioprinting attracts investors

Also in Chicago, BIOLIFE4D has filed a $50 million initial public offering with the Securities and Exchange Commission (SEC) under Regulation A+ rules.

BIOLIFE4D intend to use the funds to develop advanced tissue engineering, including a project to create “a patient-specific, fully functioning heart will be created through 3D bioprinting and the patient’s own cells”.

In the 3D bioprinting sector, San Francisco based Prellis Biologics has raised $1.8M for the development of microvasculature 3D printing tech for human organ printing. The company plan to initially focus 3D printing insulin producing tissue. Dr. Melanie Matheu, co-founder and Prellis CEO of Prellis said, “We believe our technology will jumpstart the practical use of lab-printed tissue for life-saving drug development, rapid development of human antibodies, and production of human organs for transplant.”

“Type 1 diabetics lose insulin-producing islets of langerhans at a young age. If we can replace these, we can offer diabetes patients a life free of daily insulin shots and glucose monitoring.”

Strategic partnership for Renishaw and Infosys

Renishaw and Infosys have announced a strategic partnership. The goal is to offer an end-to-end product development service, helping enterprises use additive manufacturing for production of end-use parts.

Sudip Singh, Global Head, Engineering Service at Infosys Ltd said, “Infosys has developed a rich knowledge base of AM design best practices, coupled with powerful design tools to analyse and optimise product designs, so that we can take full advantage of the flexibility that AM offers.”

Marc Saunders, Director, Global Solutions Centres at Renishaw adds, “Whilst additive manufacturing can create complex geometries in a single process step, some level of finishing is generally required to produce functional parts. Renishaw’s knowledge of metrology, machining and finishing processes can help customers to develop an integrated manufacturing solution for their innovative new product.”

Additive manufacturing for production of end use components

Based in London, Lloyd’s Register provides compliance, risk and technical consultancy services. As previously reported the enterprise published ‘Guidance Notes for the Certification of Metallic Parts made by Additive Manufacturing.’ Now the first certification of an additive manufactured component under the framework has taken place.

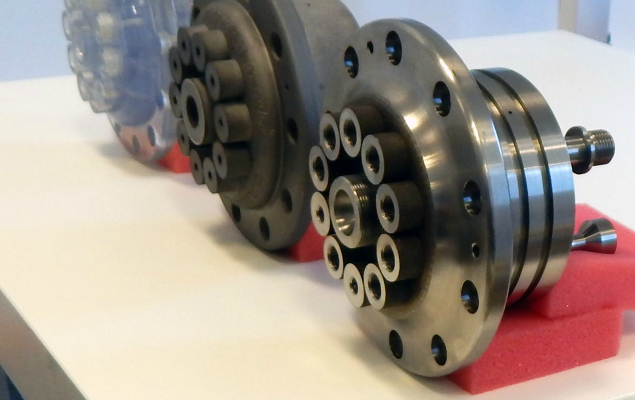

The titanium gateway manifold for pipelines in the oil and gas industry, was designed by the Safer Plug Company (SPC) and built by 3T RPD. Lloyd’s Register oversaw and certified the process via it’s framework of guidelines for manufacturers looking to produce certifiable components.

Featured image shows Safer Plug’s additive manufactured gateway manifold.