3D Printing Industry’s Executive Interview Series continues with Peter Weijmarshausen, CEO of Shapeways. Peter shared his views on past and current experiences within his world of 3D printing services for consumers with 3DPI’s Rachel Park.

3D Printing Industry: So when were you, personally, first introduced to 3D printing and can you remember the first process and part you saw? Was it a moment of enlightenment as far as Shapeways is concerned?

I called some of my old friends who use Blender and asked if they would be excited about the idea of taking their virtual 3D designs and turning them into real, physical 3D products. At first, people didn’t even believe this was even possible, but once they saw the technology, they were completely blown away. The next question I had was, “Would you pay money for this?” And the answer was, “Yes!” So I knew very quickly that there was a business model here.

The first part that was ordered from Shapeways was of a monkey statue, which was printed on a Zcorp system. That was really cool.

3D Printing Industry: Can you tell us a little about the history of Shapeways and how you have evolved from a small spin-out in the Netherlands.

Peter Weijmarshausen: The company was founded in 2007 in the lifestyle incubator of Royal Philips Electronics in Eindhoven, the Netherlands. At the time, 3D Printing was still very expensive and used primarily for rapid prototyping. People were using 3D software but thought it was impossible to hold their designs in their hands.

By 2008, we launched Shapeways.com and started 3D Printing the impossible. In 2010, we spun out of Philips and moved our headquarters over to New York.

3D Printing Industry: Can you explain the Shapeways business model for the benefit of the 3DPI audience who may not have visited the site before?

Peter Weijmarshausen: It is essentially about changing how — and when — things are made. On Shapeways, individuals can design, buy and sell their own products. We 3D print everything on-demand, which means that every order is customized and personalized.By providing a platform for our community members to share ideas and gain access to cutting edge technology, we’re bringing personalized production to everyone—whether they are already designing in 3D, want to design in 3D or are just looking to find and customize the perfect product.

It is all about just-in-timemanufacturing and products are printed to order, which eliminates the need for inventory and cuts down dramatically on waste. 3D printing technology is the key enabler for this — it is simpler AND more advanced than current manufacturing methods.

3D Printing Industry: The Shapeways business model is the conduit between talented designers and the consumer — how big do you see this getting?

Peter Weijmarshausen: I think we’re just at the start, as 3D Printing becomes more widely accepted we’re going to see more designers designing consumer ready products, and consumers that increasingly value being able to order customized creations.

Actually, I see a parallel with the software industry — if you look back to the early 1990’s where software was available on disks and CD ROMs, there were long gaps between updates and new versions and if there were problems, users had to work around them until they were fixed months later or the following year. But the Internet has changed that. Cycle times for new releases have got much shorter because of the ability to download and users can provide feedback and report bugs almost instantly, which could then be fixed within weeks, if not days.

I think something similar will happen with products. Traditionally, product development takes months and often years, but the Internet + 3D printing is changing this. I see it happening already on Shapeways. Some of our customers (the shop owners) load new product designs to the site and within days of a sale they will be getting feedback on their products, which allows them to alter and refine their designs in line with what their customers are telling them. It’s awesome to see this happening.

Traditional product development is also a very expensive, often risky thing to do. With the new business model we are creating it minimizes the risk and the investment required to bring a product to market. The biggest investment is design/modeling time and the biggest risk is a dented ego if a product does not work or is not successful.

Peter Weijmarshausen: Thank you! The opening of our factory in Long Island City was as exciting for me as it looked. We were honored to have Mayor Bloomberg there to help us commemorate the occasion and were blown away by how well attended the event was.

We see a ton of value in being close to our end users so we’re putting a great deal of effort into extending the factory and then taking it even further. I think in the future we’ll open more factories in advantageous locations for our customers.

3D Printing Industry: In terms of scale and production, it sounds very ambitious with 5 million parts / products per year projected? How many 3D printers (and different processes) do you envisage will be required to fulfill this. How far down that road are you?

Peter Weijmarshausen: Once fully built out we’ll have 30-50 3D printers at our LIC facility capable of printing 3-5 million parts a year. It’s ambitious but it’s possible and we can’t wait to see the factory come to life. We’re projecting that the factory will be fully built out by January 2014. And we do also work with partners who support our goals and what we are doing at Shapeways.

3D Printing Industry: How many different materials do you offer now, and which is the most popular?

Peter Weijmarshausen: We offer 30 different material options and variations. We’ve seen a lot of items printed in ceramic as well as plastics and metal, including silver. It really just depends on the end use for the item and what our customers want and need. We will continue to introduce new and improved materials as they develop, this is a key area for 3D printing in general and Shapeways specifically.

3D Printing Industry: What is your take on the “3D print a gun” stories doing the rounds?

Peter Weijmarshausen: Like any industry, there will be people that use innovative technologies in harmful ways. I fully understand the controversy here and don’t support any endeavor that uses 3D printing to create weapons, this being said, at Shapeways we simply just won’t print it.

3D Printing Industry: Do you like 3D printed products, do you have a favourite?

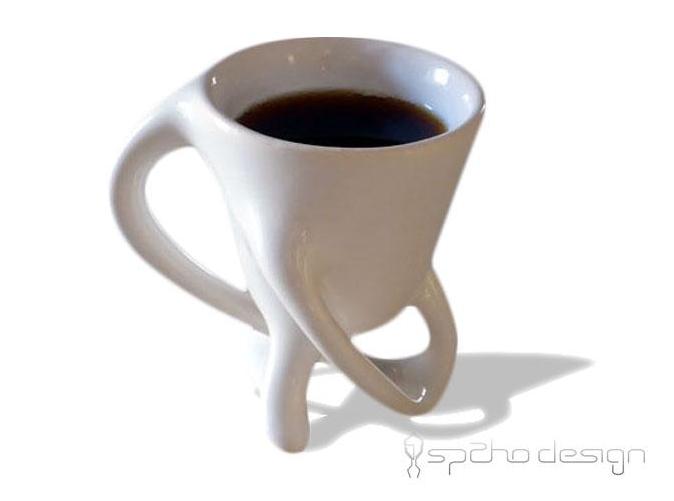

Peter Weijmarshausen: I absolutely love 3D Printed goods. Some of the lighting products are simply incredible. I currently have my eye on a couple of pieces. I have over 100 products in my own home now, and if I have to choose a current favourite, it would have to be my ceramic 3D printed coffee cup — it blends my two greatest passions: 3D printing and coffee. However more and more products appear daily and I am sure I will find new products I am blown away by shortly.

Peter Weijmarshausen: I fully believe that we will see products emerge that we’ve never even imagined before – mind blowing shapes and solutions. I envision Shapeways continuing to grow in both employee number and locations. I can’t wait to see what will happen in the next five years.