Since the outbreak of COVID-19, the world’s supply chains have been challenged like never before, causing shipping delays and the scarcity of consumer products with ever-shortening lifecycles. Add increasing political instability, climate change and trade barriers such as those erected by Brexit to the mix, and it becomes clear that the pandemic has exacerbated many existing global manufacturing issues.

In that time though, 3D printing has also grabbed the headlines in a way not seen since the early 2010s. Not only has the technology proven vital in producing COVID-19 medical supplies, but 3D printing-equipped businesses have demonstrated the ability to adapt their processes at short notice, eliminate problematic supply chains and customize goods to meet the changing demands of customers.

Now, ahead of Ultimaker’s first live Showcase, its CEO Jürgen von Hollen has spoken to 3D Printing Industry, outlining his vision for keeping pace with this shifting production environment. According to von Hollen, building a portfolio around flexibility and the idea of open innovation, has enabled Ultimaker to steal a march on its competitors, and help users ‘in-source’ to meet their supply needs.

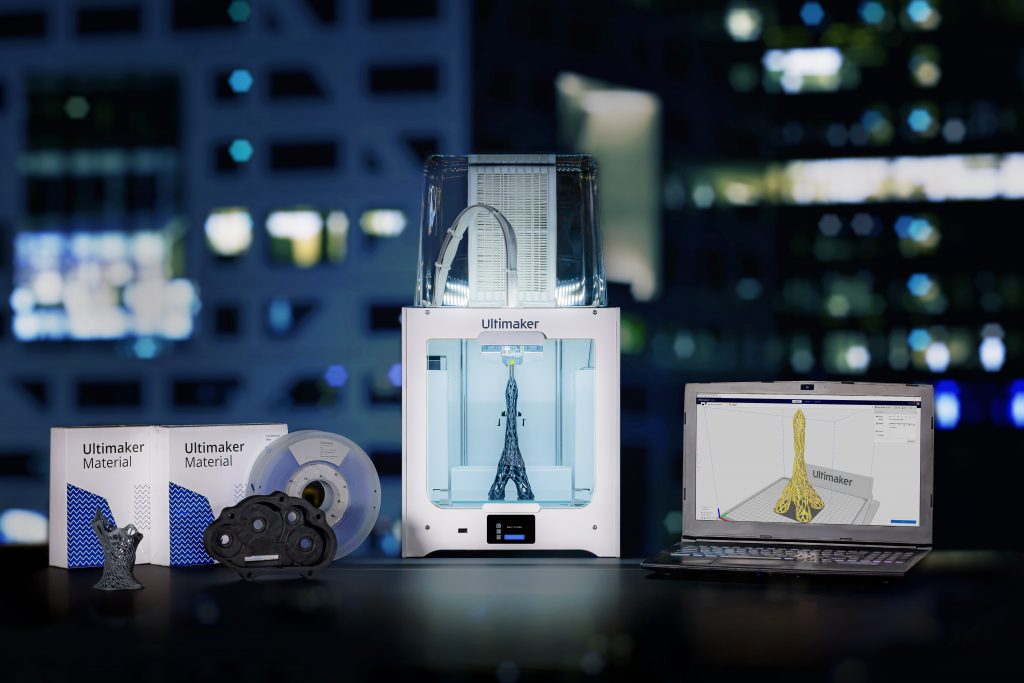

“We have created a leading 3D printing platform and ecosystem that is open, integrated and continuously evolving,” explains von Hollen. “With it, 3D printing is ready for business, and we are seeing the market respond in kind. Our Cura 3D printing software continues to grow in popularity, with over 800,000 users every month. We have also seen huge growth in Digital Factory prints this year as more customers adopt remote 3D printing.”

“Ultimaker has cracked the code on how to take the complexity out of 3D printing at a mainstream business level.”

Adopting a ‘VUCA’ mindset

First used in 1987, the term ‘VUCA,’ or Volatility, Uncertainty, Complexity and Ambiguity, is still relevant today, as an acronym to describe the complexities of the modern manufacturing world. In practise, VUCA manifests itself in incidents such as the Suez canal crisis caused by the Ever Given container ship earlier in 2021, but von Hollen says that it also “exposes society and economies in unpredictable ways.”

For businesses to be prepared for such issues, and withstand challenges in their given industry, he therefore sees flexibility as being key, not just in tackling issues but capitalizing on potential opportunities. According to Von Hollen, this means being able to pivot quickly, and redeploy engineers, processes or technologies to “address customer needs and stay ahead of the competition.”

As well as versatility, von Hollen also emphasizes how proactive management can help firms mitigate risks, and that one of the main restraints preventing manufacturing success is a lack of talent retention. In order to turn this around, empower their people, and ensure their long-term prosperity, he says that companies therefore need to develop a culture of what he refers to as “sustainable value.”

“Sustainable value is about continuity and an organization’s long-term relevance. It has several elements for successful business growth,” said von Hollen. “It’s also about having the learning culture and mechanisms in place that inspire human ingenuity, resourcefulness, and continuous improvement within our organizations.”

Tackling ‘VUCA’ via AM

In the past, von Hollen describes 3D printing as having been “a fragmented landscape” of “complex, closed ecosystems,” that included too many barriers to adoption. To make the technology truly mainstream, and help businesses overcome these obstacles, he believes that striving for flexibility and sustainable value is vital, hence he has gradually shaped Ultimaker’s platform to meet clients’ needs.

Since relocating to Utrecht in 2019, the firm has added to its portfolio significantly, launching its Enterprise software packages for new adopters, the Ultimaker S3, S5 Pro Bundle and Ultimaker 2+ Connect systems, and introducing compatibility for Lubrizol TPUs.

In doing so, the company has opened its technologies to multiple new applications, and just last year, equipment supplier ERIKS found it was able to use Ultimaker S5 Pro Bundles to 3D print food contact-safe parts. Similarly, working with Ultimaker, 3D Metalforge has established a Singaporian print farm of S3 machines, with which it’s targeting the Southeast Asian defense, maritime, medical, and oil and gas sectors.

For his part, von Hollen says that he’s seeing a growing number of clients adopt 3D printing to produce bespoke products remotely, in a way which would be impossible with a fixed production process. In future, he believes this trend will continue, bringing the manufacturing of goods “closer to the consumer,” and allowing products to be cost-effectively customized to customers’ needs on an expanded global scale.

“With 3D printing now moving rapidly from hobbyist tech to a maturing professional platform, it is here for the long haul, and Ultimaker is leading the way,” adds von Hollen. “While the 3D tech sector focused on its own technology, Ultimaker also made it about a customer-centric platform of hardware, software, materials, and a world-class network of expert partners.”

Ultimaker’s live showcase

Von Hollen is planning to elaborate on his ideas around facing these VUCA challenges during his keynote speech at Ultimaker’s Showcase event next month. As well as exploring these themes in more detail, the event will also see him demonstrate how Ultimaker is bringing products to market that help its customers meet global supply chain challenges.

During the one-hour online show, attendees will gain an insight into the firm’s most recent and upcoming software updates, including how they can transform a manufacturing workflow for the better. Ultimaker also intends to outline the latest features of its machines, as well as unveiling new business partnerships, and additions to its academy course roster.

Finally, and potentially most significantly, the company has teased “exciting announcements” about its product ecosystem as well. In fact, von Hollen says the event will showcase “the next evolution in Ultimaker’s leading 3D printing platform,” and that attendees will get the chance to see first-hand the “transformative impact that a truly integrated additive manufacturing solution can offer businesses.”

“It won’t just be about new announcements,” he adds. “We’ll also be showcasing ecosystem partners and customers who are already benefiting from being part of this 3D printing ecosystem, who are driving the transformation of supply chains and production workflows needed to thrive in the ‘VUCA’ world.”

Ultimaker’s Showcase is set to be live-streamed on Youtube on Thursday, October 14, 2021, at 5pm CEST or 11am EST, and readers can find out more about what to expect here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

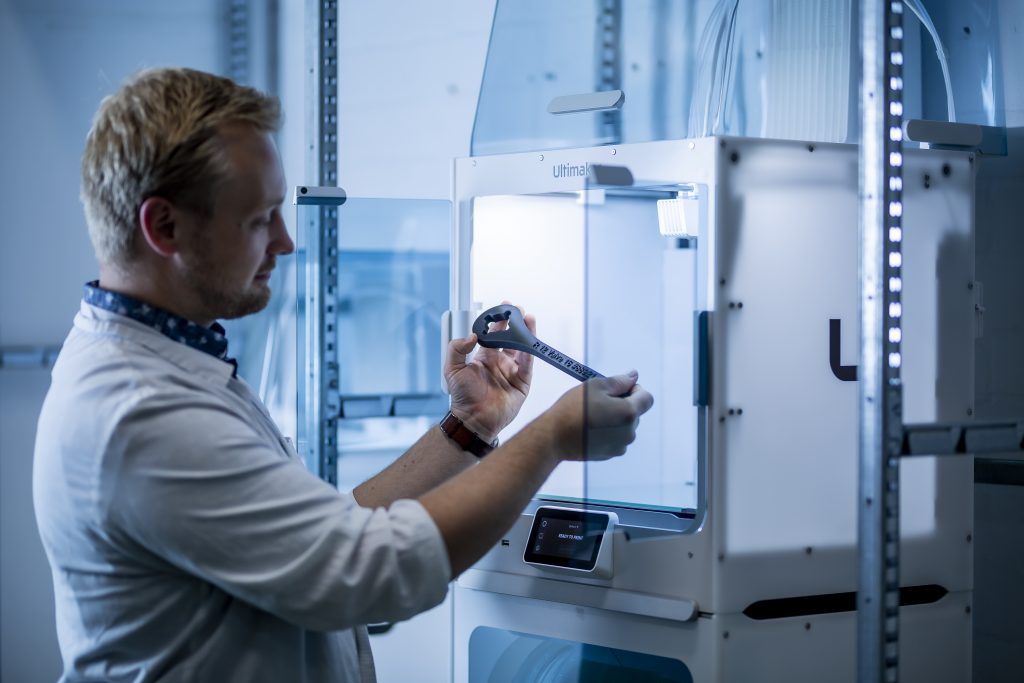

Featured image shows an engineer using an Ultimaker system to 3D print tooling. Photo via Ultimaker.