TOffeeAM joins the 2020 formnext start-up challenge winners. The UK-based enterprise is focused on unlocking the potential of additive manufacturing via topology optimization.

I caught up with Audrey Gaymann, CTO and co-Founder at TOffeeAM to learn more.

3PDI: When was your company founded and where are operations based?

AG: The company was incorporated in March 2019. However, the development of the software started as a research project in 2015 at Imperial College London. Over the years, the research started to attract attention and was awarded numerous prizes, which lead to the creation of TOffeeAM LTD.

In July 2020, TOffeeAM finished on a seed round, raising 1 million euros to grow even further. We are currently based in London, in the UK.

3DPI: Can you tell us more about your team’s background and experience with AM?

AG: Francesco Montomoli is a lecturer at Imperial College London in the Aeronautics Department. Marco and I started Ph.D.s under his supervision in 2015 and started to work on what is now the core topology optimization software of TOffeeAM.

The company now has 9 employees on payroll in the UK with a background in engineering and science, and mostly hold PhDs. As for traction, TOffeeAM expanded internationally not only with Baker Hughes but also with GE Aviation (Germany), an F1 Team (EU), and two Tier 1 companies in the US, a car manufacturer, and an aerospace giant.

We have been working closely with AM companies for the past 5 years to validate our designs and make them robust to uncertainty brought forth by AM.

3DPI: What does your company do?

AG: The development of Additive Manufacturing (AM) over the past decades has brought new potential for the manufacture of engineering components. 3D printers can be used to automatically mass-produce three-dimensional components in metal or polymers with very little manufacturing constraints. However, the democratisation of the use of AM has also brought new challenges. Though it offers new flexibility to the production of engineering components as compared to traditional manufacturing methods, it can be assessed that AM is being used to mass-produce components for which the designs was done with manufacturing constraints in minds. Consequently, the need for a new design method that can fully exploit the flexibility by AM started to arise.

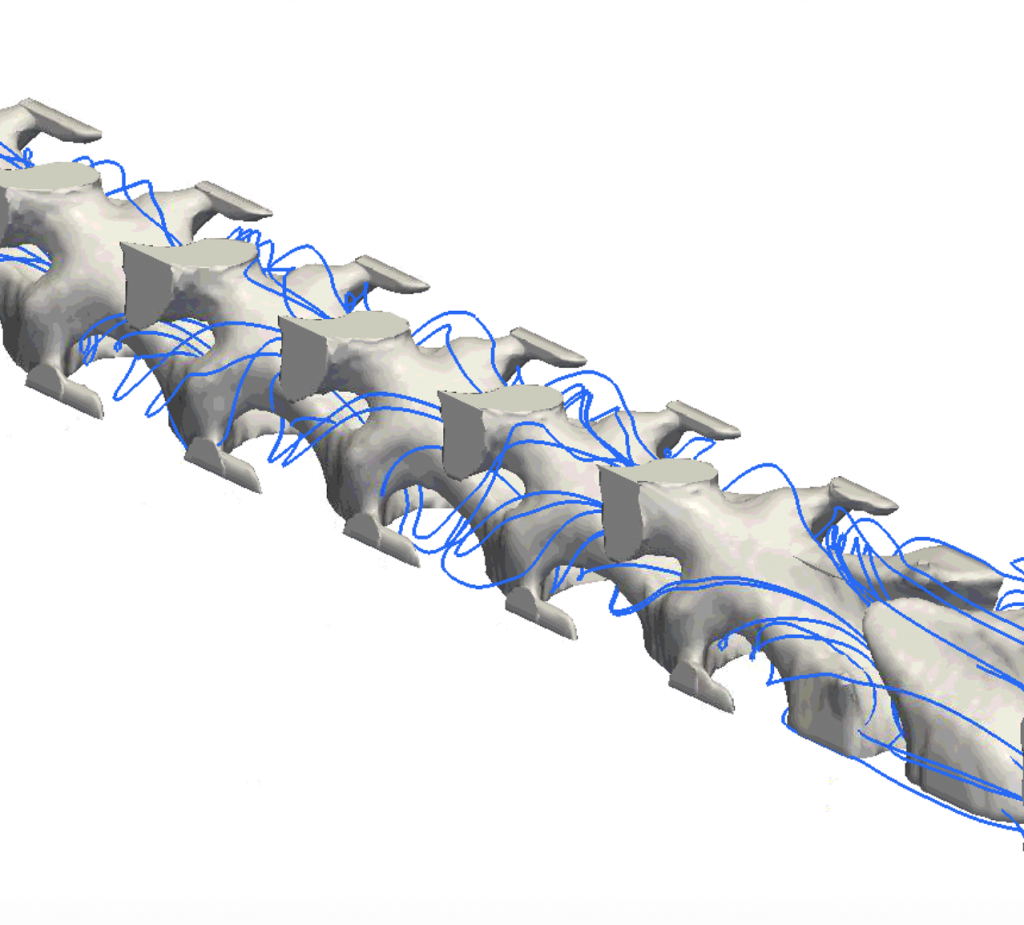

In this context, the development of Topology Optimisation (TO) started. TO is a mathematical approach that relies on the calculation of a metric that describes the performance of a component. The component design is changed accordingly to its performance value until a maximum is reached. TO has the potential to enhance performance and efficiency of engineering components beyond their current capabilities.

TOffeeAM licenses software based on topology optimisation for additive manufacturing. This software represents the latest advancement in the field of topology optimisation for fluid-structure problems and it is going towards commercialisation. We have also recently developed a design software for drones that is available separately from our main TO software.

3DPI: How does your company fit into the additive manufacturing ecosystem?

The design produced by our software is done considering the new flexibility found by AM. We are licensing a design software that output optimum engineering components for their purpose. Those designs being highly complex, they are made to be manufactured using AM.

3DPI: How would you describe the roadmap for your enterprise in the coming years?

AG: Our vision for TOffeeAM is that it will grow similarly to previous successful spin-outs of ICL. We are working to make TOffeeAM the leader in design software for additive manufacturing.

The money raised during our seed round is used to scale the company by hiring employees to tackle requests from our customers. The company will grow even further in the coming months, considering that the Total Addressable Market (TAM) of Additive Manufacturing (AM) will represent by 2024 a $35.6bn revenue market. The current growth rate is 30% every year as the automation of manufacturing sites becomes more and more available worldwide. The growing interest in AM has enabled to cut down the cost associated with items produced with it and the development/ research of AM techniques ensure nowadays great reliability of the components manufactured.

The Serviceable Addressable Market (SAM) for design for additive manufacturing, and thus topology optimisation, has currently an addressable market estimated at $1.8bn. It is a key sector for the AM market as the geometrical freedom that fully exploit AM will be brought by new TO software.

3DPI: Is there anything else you would like our readers to know?

AG: To celebrate our Formnext victory we will offer a 50% discount to any attendee of Formnext. Please do let us know while filling our online form. Finally, we currently hiring and searching for the best talents.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.