The 3D Printing Industry Awards 2022 shortlists are now available for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

Bangalore-based 3D printer manufacturer Intech Additive Solutions has announced the launch of a new Laser Powder Bed Fusion (LPBF) system at Formnext.

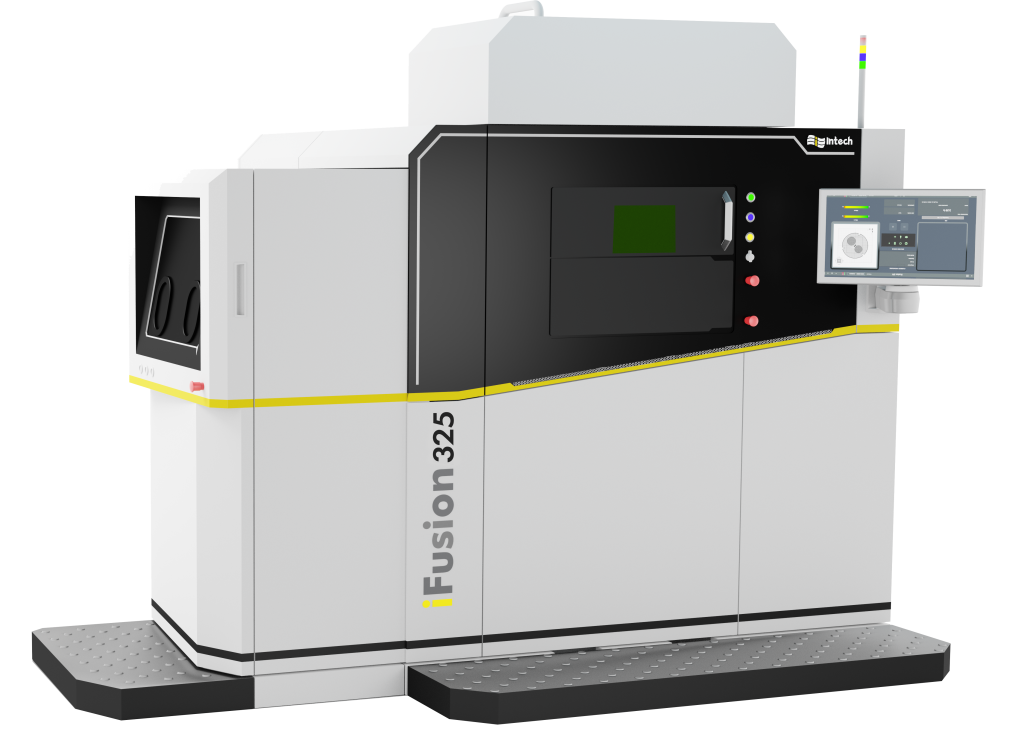

Available in single and multi-laser configurations, each Intech Additive Solutions iFusion325 3D printer features full-field scanning capabilities and a large 325mm x 325mm x 420mm build volume. As a result, the machine enables the production of mid-to-large sized functional parts, with potential applications in the aerospace, automotive, medical, dental, education and defense industries.

“Following the successful launch of iFusion150 2nd gen, we are excited to have showcased the iFusion325 at Formnext,” said Sridhar Balram, Founder and CEO of Intech Additive Solutions. “This solution will cater to diverse additive manufacturing (AM) requirements, which is ideal for various industry verticals. We anticipate this machine to be one of the bestselling products from our portfolio in the future.”

Intech Additive Solutions’ metal AM offering

Founded back in 2012, Intech Additive Solutions prides itself on being the first Indian OEM to develop and supply LPBF 3D printers. Since launching its debut system, the iFusion150, in 2020, the company has gone on to expand its portfolio with the release of the larger 450mm x 450mm x 450mm iFusion450, in addition to broadening its software offering.

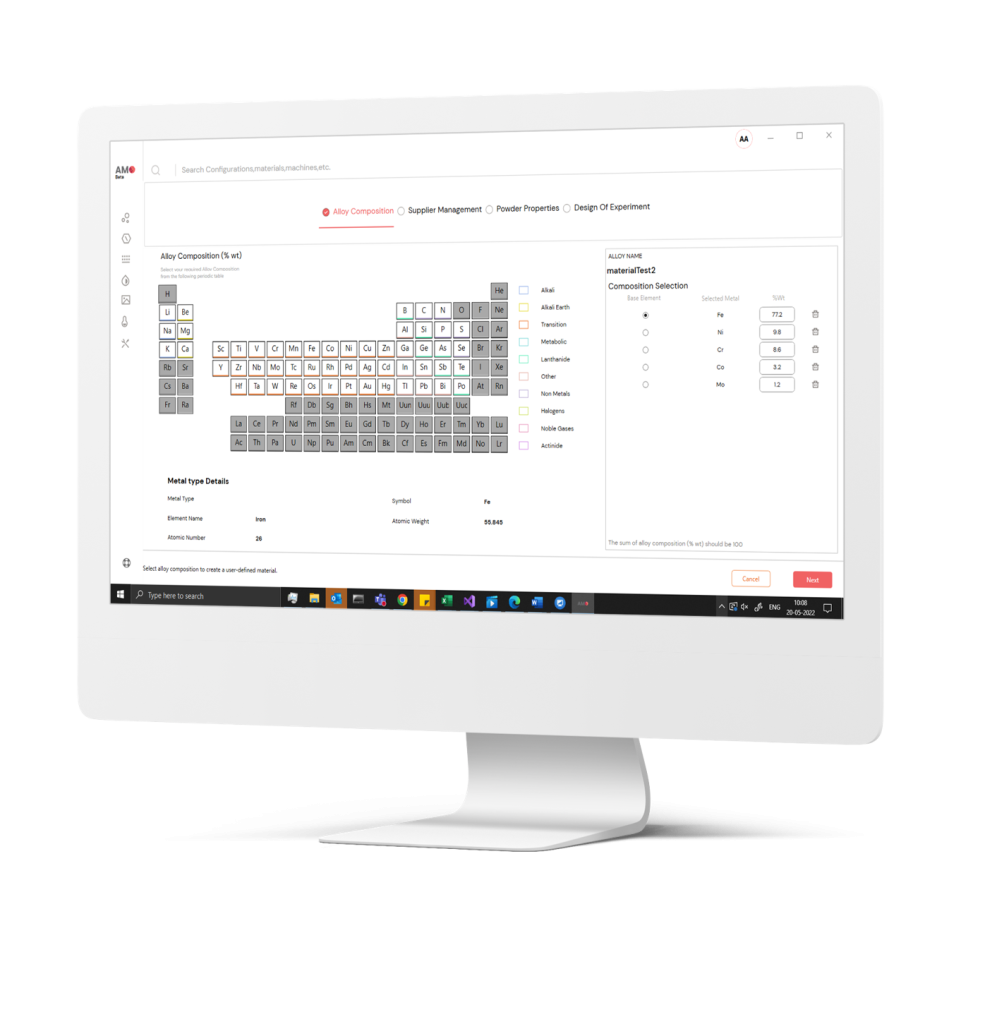

Alongside its growing suite of 3D printers, has developed the AMBuilder build preparation software. Compatible with any LPBF system on the market, the program features distortion analysis, orientation optimization and support generation tools. AM Builder also has built-in slicer and path generation functionalities, which are said to allow users to slash build times and enhance the surface quality of parts.

To supplement AMBuilder, the company has also introduced AMOptomet, a parameter optimization software that helps simplify users’ 3D printing workflows and reduce print processing workloads. During Formnext, Intech Additive Solutions announced that it has developed an update to the platform with UIT-Dresden, designed to improve its parameter prediction and optimization capabilities.

“AMOptoMet helps in printing parts “Right First time” and reduces the time taken for the Design of Experiments (DOE) when developing parameters to print new materials,” added Balaram. “UIT-Dresden’s use of AMOptoMet in their research projects further validates the software and gives us invaluable feedback to incorporate features to address new and emerging applications and materials in metal 3D printing.”

Rolling out the iFusion325 at Formnext

Intech Additive Solutions has specifically developed its latest machine to tackle the cost, material consumption, lead time and part quality challenges faced by manufacturers. One way the machine addresses these issues is with its openness to customization. The iFusion325 is available in single or multi-laser versions, and the Yb-Fiber lasers in each iteration can be deployed at 500W or more.

At 325mm x 325mm x 420mm, Intech Additive Solutions says the machine also has one of the largest build volumes in its class, enabling it to produce both large builds and high volumes of small components. In fact, the company claims its new system’s large build area allows “more parts to be nested and stacked during a single build,” in a way that efficiently increases users’ productivity.

Elsewhere, to help adopters ensure that parts can be printed quickly and uniformly, the firm has fitted the machine with a build plate-leveling motor, as well as dual compartments, which help reduce flooding time due to inert gas retainment.

Technical specifications and pricing

Below are the technical specifications for the Intech Additive Solutions iFusion325 3D printer. While the machine is available to order now, those seeking pricing information will need to request a quote from Intech Additive Solutions.

| Technology | Laser Powder Bed Fusion (LPBF) |

| Build Volume | 325mm x 325mm x 420mm |

| Laser Type | 500W Yb – Fibre Laser |

| Build Platform Heating | 2000°C |

| Scan Speed | 7 m/s max |

| Focus Diameter | Min. 80um |

| Software | AMBuilder, AMOptomet |

Check out our full Formnext news round-up for the latest from 3D printing’s leading trade show.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Intech Additive Solutions’ iFusion325 3D printer. Photo via Intech Additive Solutions.