April was a busy month for the 3D printing industry and featured two must attend events.

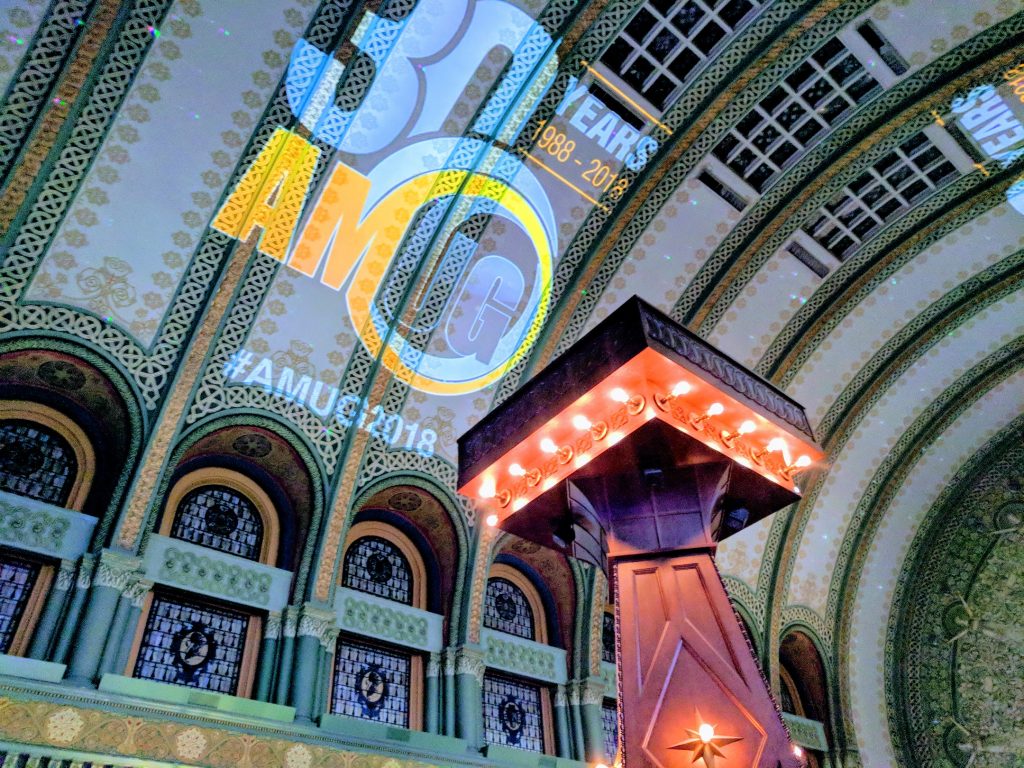

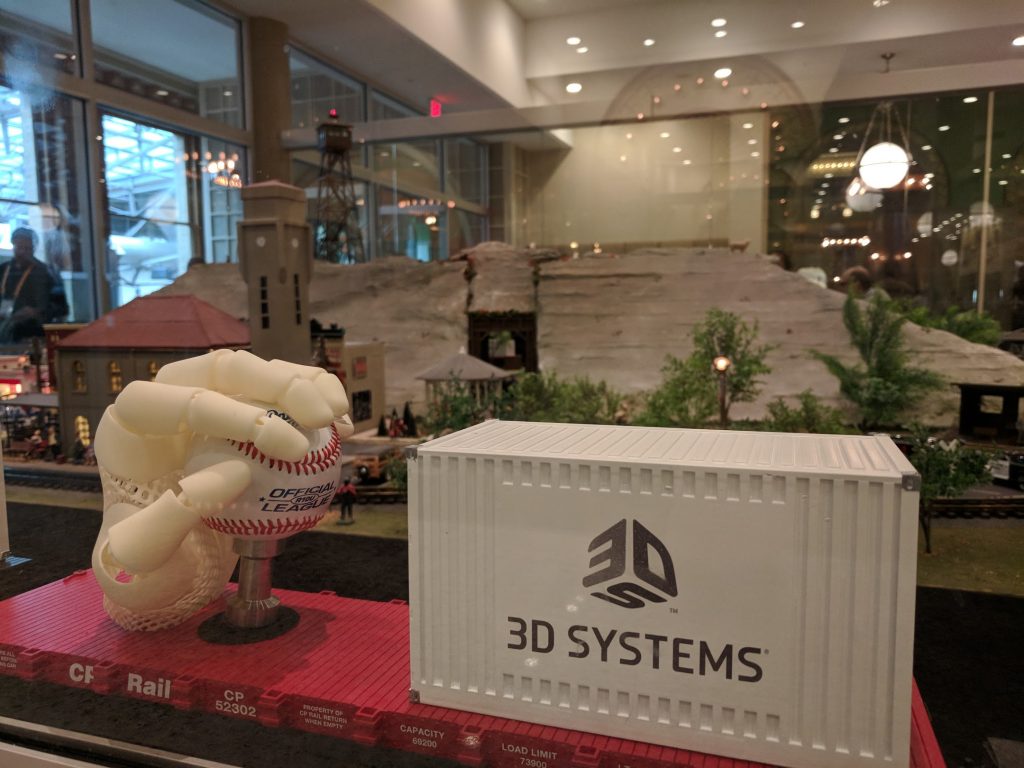

3D Printing Industry was of course at last weeks RAPID + TCT and also the AMUG Conference 2018 earlier in the month. What began in 1988 as user group for the owners of 3D Systems equipment has grown to become the brains trust of additive manufacturing. The AMUG Conference is now in its 30th year and addresses practically every aspect of industrial 3D printing.

Wandering around the impressive St. Louis Union Station hotel in the pre-show hours before the AMUG 2018 Conference, you begin to understand how this event is unlike others on the ever expanding additive manufacturing calendar.

As the final touches were put to booths and more delegates began to arrive early on a subzero Sunday morning, around every corner you hear friendly greetings. Many of the attendees are old friends, former colleagues and veterans of the industry. Unlike any event I have attended before the AMUG Conference has a remarkable openness, sharing of best practices and genuine willingness to advance the industry as a whole.

AMUG is also staffed by volunteers, when collecting my press credentials it was a pleasant surprise to see the CEO of one company working at the registration desk.

That’s not to say newcomers are unwelcome. This was my first time at the AMUG Conference, and among the familiar faces I also met fellow first timers. They have come to learn from what is surely the largest gathering of additive manufacturing manufacturing experts in the world.

By the end of the week many of those newcomers had already decided upon a return for 2019.

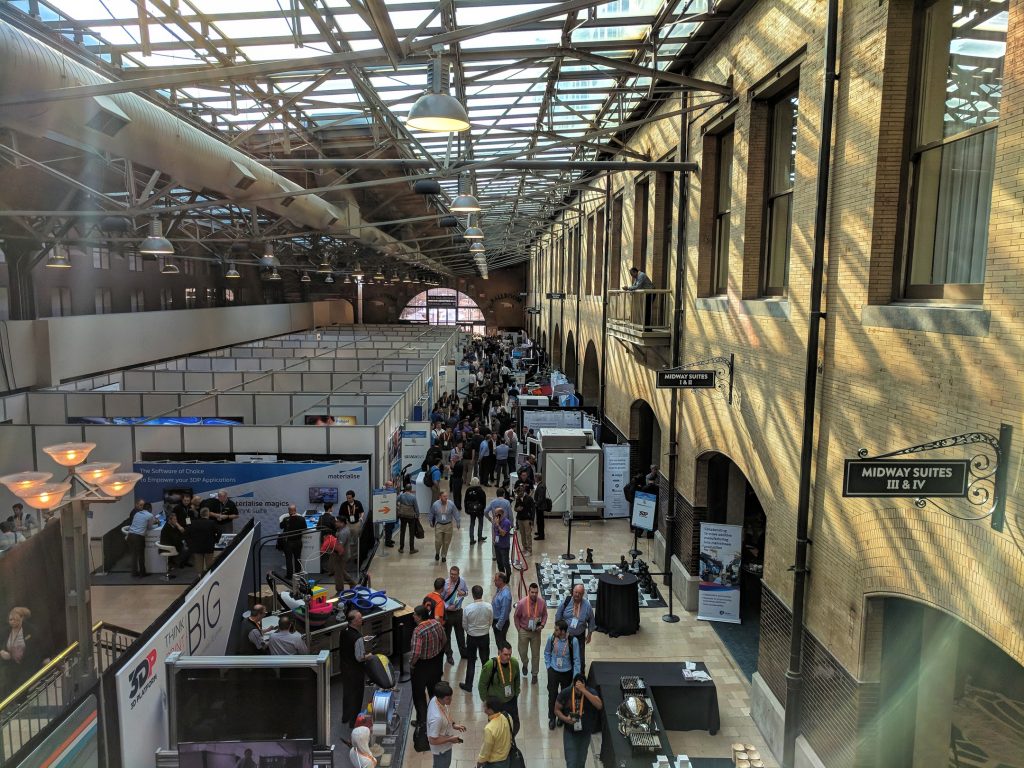

While some events boast booth space in the tens of thousands of square feet, the AMUG conference’s attraction is the technical expertise – with an unrivalled program of seminars, presentations, user group events and learning opportunities.

Every part of the AMUG Conference experience is intended to facilitate this exchange of information, from the seating plans at lunch to ensuring attendees have no real reason to leave the hotel – other than an evening excursion to the local NASCAR track!

I caught up with some of this years AMUG Conference attendees to gather their thoughts on the event and how they would like to see the additive manufacturing industry develop in 2018.

3D Printing Industry: How was your experience at the AMUG Conference?

Dan Straka, General Manager, InterPRO Additive Manufacturing Group: Great as always! For me it is about connecting with people. We each have our own little corners of the world and it’s important to leave that space and learn, not only where the industry is going, but also how people are solving daily problems with additive.

Josh Hope, Sr. Manager, 3D Printing & Engineering Projects, Mimaki USA: This was our first AMUG experience and we will definitely be back. We were pleasantly surprised at the high quality of conversations and the ability to spend time with people from so many different markets.

Philipp Stelzer, Head of Sales & Marketing, 3YOURMIND: We had a fantastic AMUG 2018. It was 5 days packed with interesting conversations, presentations and activities.

Carmel Monti, iSQUARED: We had an excellent show. More activity and interest than we even expected.

Ron Clemons, Additive Manufacturing Sr. Product Sales Specialist, ANSYS: Very good. Great to have so many major AM players in one place. Booth traffic was strong. Expo layout was not great due to venue. Great conference selection.

Dale Heuermann, Mechanical Design Engineer, Dinsmore Inc: AMUG was great, the choices of lectures and workshops to go to was expansive and there was always one in each session that was valuable for myself and Dinsmore Inc.

Marc Saunders, Director, Global Solutions Centres, Renishaw: AMUG is a dynamic event, with great engagement with the members. Education and knowledge sharing was the main focus – the strongest interest was in presentations with technical depth.

Valerie Buckingham, VP Marketing at Carbon, Inc.: I love coming back to AMUG. It’s such a unique experience compared to other industry events in that it’s a true community of like-minded users who are passionate about the future of additive, and directly involved. Everyone is friendly and open. It’s amazing that such an ambitious and growing event is put on by an all-volunteer board.

Andrew Sliwa, Managing Director, Custom Prototypes: This is our 4th time at AMUG and since we are getting to know more and more people we feel like members of the family. We were there in two capacities as a conference attendees and sponsors. As a sponsor you have the access to the key people. Somebody said that AMUG has the biggest signal to noise ratio. In my opinion that’s a perfect statement describing this event.

Bruce Bradshaw, Chief Business & Marketing Officer, Evolve Additive Solutions: AMUG is a very unique event from other trade shows or conferences. It brings together the brightest minds, most experienced professional users on the planet. It also affords more networking opportunities due to its format. As someone who has participated in this event for over 10 years, both as an exhibitor and attendee AMUG is a must for serious additive professionals.

3D Printing Industry: What are your key takeaways from AMUG 2018?

Dan Straka, General Manager, InterPRO Additive Manufacturing Group: The two previous years felt like the roll outs of new machines was the focus. This year, at least for the polymer side, I felt like material science started to take the spotlight. DSM had a new Nylon + CF material that I am very excited about.

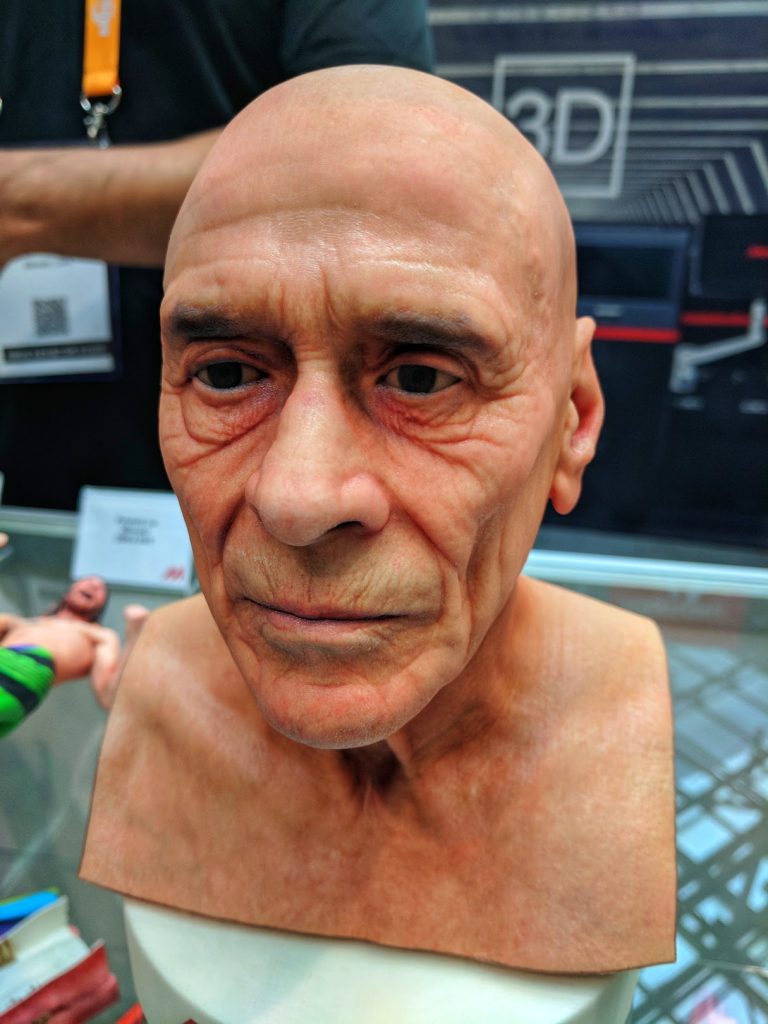

Josh Hope, Sr. Manager, 3D Printing & Engineering Projects, Mimaki USA: It was great to see how many people were interested and excited about full color 3D parts. In the coming years we will be seeing more and more crossover from the more creative side to the more industrial side of additive manufacturing as the developing technologies blend together.

Philipp Stelzer, Head of Sales & Marketing, 3YOURMIND: As it was the first AMUG I participated in, it was great to see that the focus is really on knowledge sharing and the commitment of everyone to push the industry forward.

Carmel Monti, iSQUARED: How much opportunity there is for our product line. There is a real need for our product.

Ron Clemons, Additive Manufacturing Sr. Product Sales Specialist, ANSYS: After 21 years in AM, I am now seeing real change, real evolution of the industry. Growing selection of technologies serving more upstream, downstream and advanced applications. Moving toward in-earnest production for rigorous vertical markets.

Dale Heuermann, Mechanical Design Engineer, Dinsmore Inc: It is an exciting time for the additive manufacturing field as we begin to venture out into true end part production and all that goes with qualification and validation.

Marc Saunders, Director – Global Solutions Centres, Renishaw: AM users are getting practical – they have moved beyond feasibility studies and are focusing on qualifying AM processes for production.

Valerie Buckingham, VP Marketing at Carbon, Inc.: A year ago, Carbon showed up at AMUG with the launch of our SpeedCell product, and what was then considered a provocative tagline of “Stop Prototyping, Start Producing”. Now, only a year later, I can’t believe how quickly the whole industry has followed suit, evolving from a largely prototyping mindset towards one of true production.

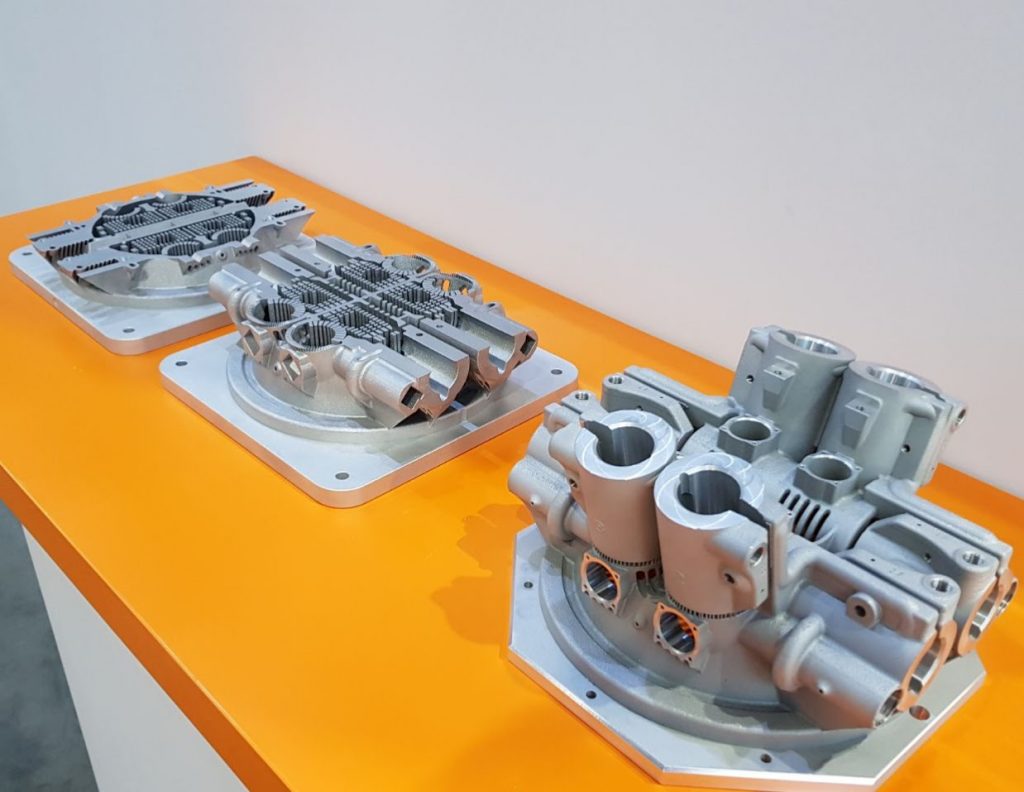

Andrew Sliwa, Managing Director, Custom Prototypes: We have recently got involved in metal 3D printing and of course have tons of issues about how to run the system. We asked the industry leaders and they were happy to answer our questions. The same refers to our workflow issues. We managed to get in touch with companies who offered us free trials of their software so we can evaluate it.

Bruce Bradshaw, Chief Business & Marketing Officer, Evolve Additive Solutions: Its clear that AM is now moving into manufacturing applications. Metal and polymer technologies focused on manufacturing applications seem to be the topic of choice from not only vendors, but also many of the attendees at the conference.

3D Printing Industry: How would you like to see Additive Manufacturing develop in 2018?

Dan Straka, General Manager, InterPRO Additive Manufacturing Group: Materials! The capabilities of any 3DP machine are important and adds value to the end product/part, but material properties lead the way.

Josh Hope, Sr. Manager, 3D Printing & Engineering Projects, Mimaki USA: Greater adoption of full color 3D prints and parts of course!

Philipp Stelzer, Head of Sales & Marketing, 3YOURMIND: I believe it will be key to the industry that we see more big players like BMW making commitments to set up AM production hubs. That way the entire market will be pushed further towards the production of serial parts.

Ron Clemons, Additive Manufacturing Sr. Product Sales Specialist, ANSYS: More specialization of products rather than just all-purpose platforms and more advanced and automated parts manufacturers–production lines vs. prototype job shops. More production standards around AM.

Dale Heuermann, Mechanical Design Engineer, Dinsmore Inc: To continue making strides to come along traditional manufacturing methods to produce end use parts.

Marc Saunders, Director – Global Solutions Centres, Renishaw: A better understanding of the AM process is critical, both in the virtual world and in practice. We are seeing advances in software tools that simulate the AM process to enable optimised part designs, underpinned by real-time sensor data to validate process execution and reduce reliance on post-process inspection.

Valerie Buckingham, VP Marketing at Carbon, Inc.: This year, our customers and community were so supportive as we launched the Carbon certification program, a program we developed specifically for both users and our production partners. Deep, ongoing certification and education is something that has really been missing in our industry. In 2018, I hope to see a lot more users getting in-depth training in additive design and processes so we can accelerate the adoption of 3D manufacturing overall.

Andrew Sliwa, Managing Director, Custom Prototypes: The technology develops very fast. I am personally very intrigued by the “multi laser spacial 3d printing” which is one step ahead of what we see now (2d printing with Z axis). This new process has been developed in couple of places in the World and I am sure we will see the first prototype of this system next year.

Bruce Bradshaw, Chief Business & Marketing Officer, Evolve Additive Solutions: All boats rise in a rising tide… With this said I would like to see more interaction/partnerships between AM vendors focused on manufacturing with other areas of manufacturing – software, autonomous carts, Industry 4.0. This will ensure organizations that are on the fence about additive feel more comfortable that Additive is a real technology that can impact their production operations.

The next major event on the AM calendar is just around the corner when on May 17th, the leaders of 3D printing industry will meet in London. Vote now for the leading industrial additive manufacturing systems in the 2018 3D Printing Industry Awards.

For more of the latest additive manufacturing insights subscribe to our daily 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing. The 3D Printing Jobs board is live – registration is free for employers and job seekers.