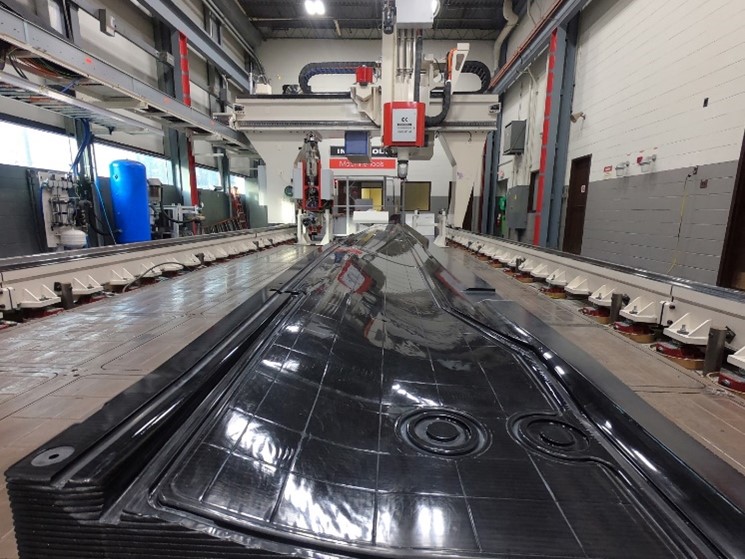

Manufacturing system provider Ingersoll Machine Tools has partnered with aviation company Bell to 3D print a 22 foot-long vacuum trim tool – a mold used for the production of helicopter rotor blades.

The project, which resulted in major lead time savings, was completed using Ingersoll’s own large-format hybrid MasterPrint system, a gantry-based 3D printer with integrated 5-axis milling functionality. According to Ingersoll, the MasterPrint is the largest polymer 3D printer in the world. Designed specifically for the production of extra-large production parts, the system can be found at Ingersoll’s headquarters in Rockford, IL.

“We are continuously testing and advancing MasterPrint in our Development Center” said Chip Storie, CEO at Ingersoll. “Among Ingersoll’s short-term objectives is for MasterPrint to 3D print molds for aerospace that preserve the geometrical properties and tolerances, vacuum integrity and autoclave resilience normally obtained with traditional technology, but with the cost and time reduction only additive manufacturing can offer. The relentless progress our MasterPrint process has made in 2020 has finally made this target attainable.”

1,150 lb of ABS

The vacuum trim tool was composed of 1,150 lb of ABS with a 20% chopped carbon fiber fill, and took around 75 hours to print from start to finish. Once the print was complete, the mold surfaces and additional tooling location features were machined into the part by switching out the print module for a 5-axis milling head.

The milling process was completed in another week and the final trim tool was made to be fully vacuum-tight. Both the 3D printing and machining operations on the MasterPrint utilize a Siemens 840D CNC control system.

By opting to 3D print the part instead of machining a large-scale mold, the partners were able to cut the project’s lead time significantly. With the additive and subtractive portions of the workflow co-engineered in one native CAD software format, the manufacturing process as a whole took around 3 weeks. In contrast, the traditional build cycle for a typical aluminum mold of this size would take between four and five months.

James Cordell, Sr. Manager of Process Stability at Bell, adds, “For many years Bell has utilized composite materials for manufacturing airframe components, including components produced on an Ingersoll Machine Tools Tape Layer machine. These similar materials are now being utilized for manufacturing the molds that form the airframe components. Utilizing this rapid manufacturing equipment will allow Bell to greatly accelerate our development of tooling for many applications within the Bell organization.”

Large part production with the MasterPrint

This isn’t the first time Ingersoll’s MasterPrint 3D printer has been leveraged for its large part production capabilities. Earlier this year, the University of Maine (UMaine) secured $2.8 million in funding from the U.S. Department of Energy (DoE) to develop a more eco-friendly method of 3D printing wind turbine blade molds. Using a custom variant of the MasterPrint, the researchers are now in the process of creating their blade molds in a bio-based nanocellulose feedstock. Once complete, the project is expected to slash lead times by months and yield cost savings of 25 – 50%.

Previously, UMaine has also used its custom MasterPrint system to fabricate the world’s largest 3D printed solid object (and largest 3D printed boat). The 25-foot, 5000-pound 3D printed boat is called 3Dirigo and it has already been tested and christened at the university. It was produced in just three days using a blend of plastic and wood cellulose.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the final 22-foot-long vacuum trim tool. Photo via Ingersoll.