The past month has yielded several announcements from the copper 3D printing sector.

Infinite Flex, a Germany-based developer of smart materials, recently launched what it claims to be the world’s first pure copper powder for SLM 3D printing. Dubbed INFINITE POWDER Cu 01, the material has already been successfully tested on a number of standard SLM 3D printers such as the EOS M290 and Trumpf TruPrint 1000, and is now commercially available.

Elsewhere, UK-based alloy design firm Alloyed recently showcased its latest copper 3D printing application – a highly optimized cooling plate for use in high-performance temperature regulation applications.

Michael Holmes, MD at Alloyed, said, “The cooling plate is a great example of what can be done when optimized AM geometry is combined with optimized AM material properties.”

Infinite Flex’s INFINITE POWDER Cu 01

Pure copper is well known for its excellent electrical and thermal conductivity, making it the universal material of choice for wiring and heat transfer components such as heat exchangers, piping, and heat sinks. Unfortunately, pure copper is also extremely difficult to process using laser-based 3D printing systems due to both its conductivity and high reflectivity, which renders high-power laser beams useless.

To address this, materials companies have developed a number of copper alloys such as CuCrZr or CuNiSiCr, but these alloys often offer significantly poorer conductivity characteristics than their pure counterpart. Infinite Flex states that, as a result, 3D printed copper parts so far simply haven’t been able to deliver the properties of traditionally manufactured copper.

The firm believes the answer to the problem lies in its new INFINITE POWDER Cu 01 material, a new pure copper powder designed specifically for SLM 3D printers. The powder offers a tensile strength of over 220MPa, an elongation of 24%, and results in high-density parts (>99.9%). Infinite Flex believes its latest launch will enable a new wave of high-performance 3D printing applications such as heat exchangers, induction coils, and electronics components.

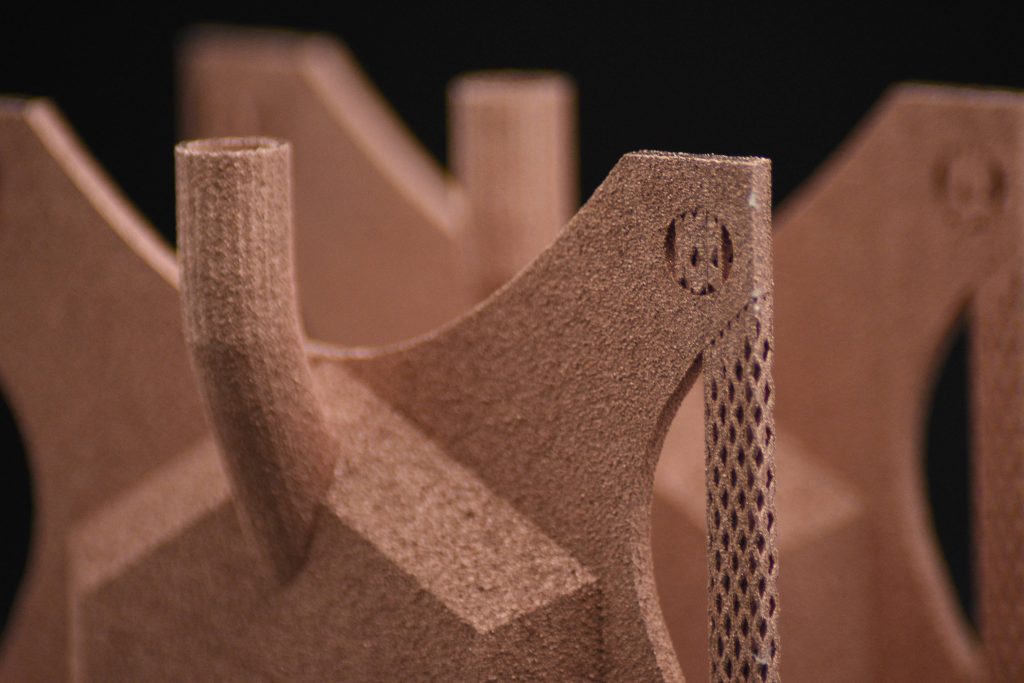

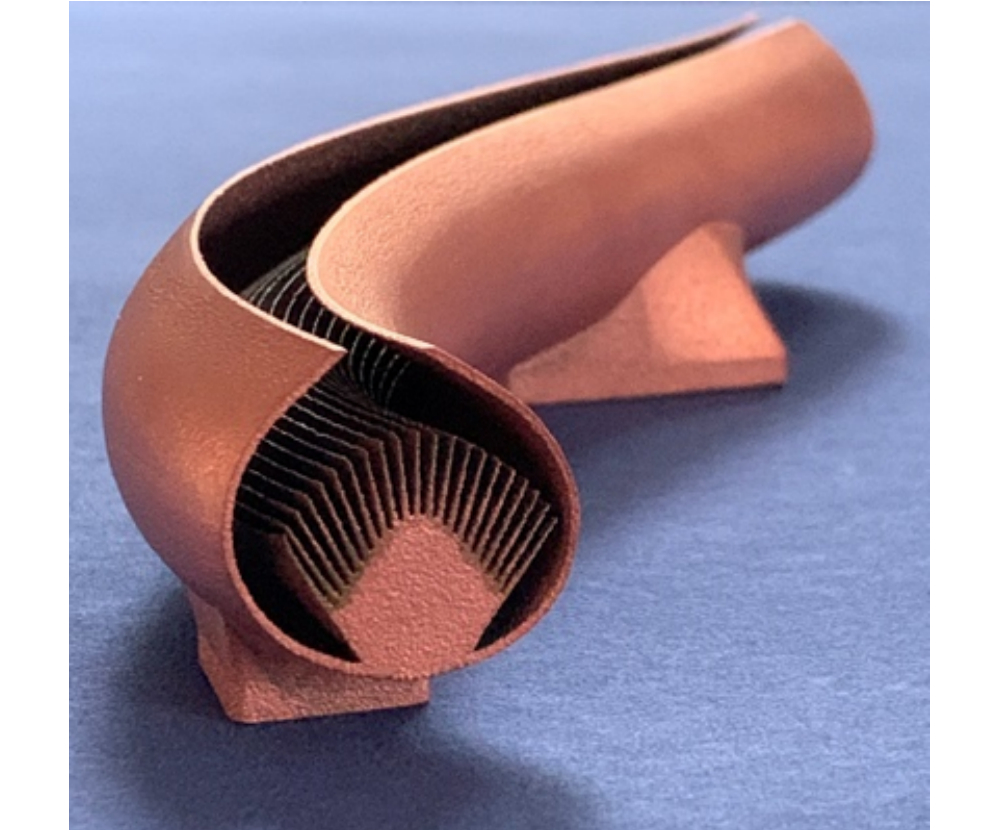

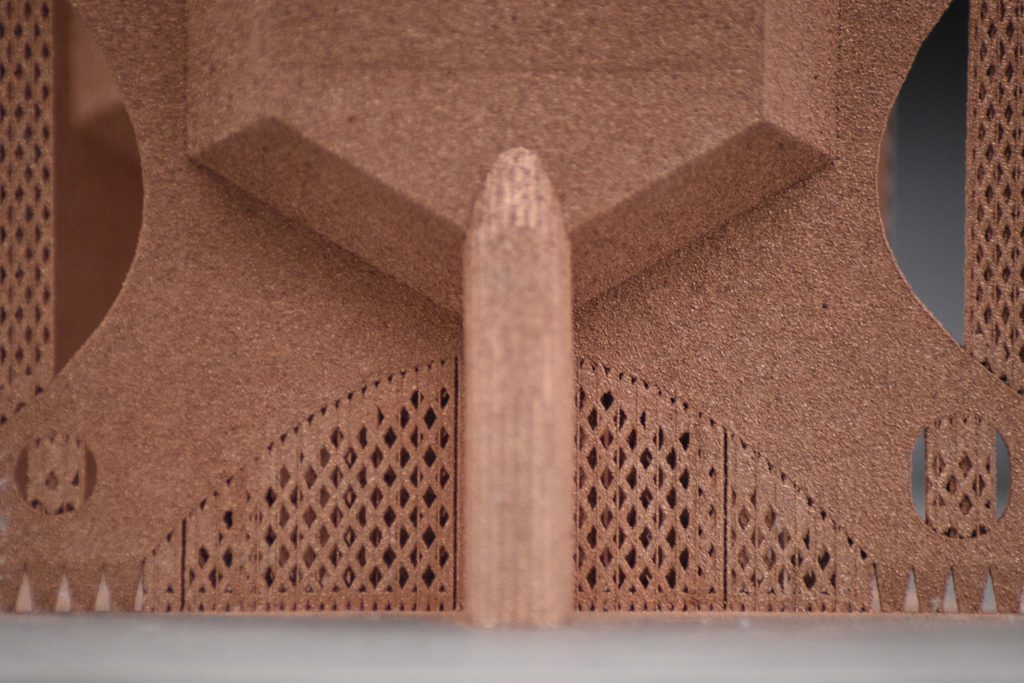

Alloyed’s 3D printed copper cooling plate

Alloyed’s 3D printed copper cooling plate is designed for use in high-temperature computing systems such as data centers and in general liquid cooling systems. The part features a 3D printing-enabled lattice geometry that combines functionality and performance, all while minimizing material usage.

Additionally, the monolithic nature of the printed cooling plate means it’s both simpler and more efficient at transferring heat than traditionally assembled cold plates. In fact, since it doesn’t need to be assembled at all, it proved easier to install and benefits from lower maintenance requirements. The result is greater performance when it comes to reducing energy usage when compared to conventional air cooling methods.

To enable the project, Alloyed partnered with JX Nippon Mining & Metals (JXNMM), a specialist in copper powder development. JXNMM has a history of developing copper powders with improved 3D printability, which is does via a novel surface treatment process that prevents an increase in oxygen content in the powder. In the context of laser-based 3D printing systems, this means an increase in absorptivity, which leads to improved printability.

Enrique Alabort, co-founder of Alloyed and Head of Alloyed Japan, explains, “The success of the copper cooling plate is due to the combined expertise of Alloyed and JXNMM. The materials developed by JX allow Alloyed to use its proprietary Engine® and Architect® software to produce the high-fidelity complex geometries and lattice structures in the cooling plate.”

In other copper news, binder jet 3D printer manufacturer ExOne recently teamed up with Tennessee-based start-up Maxxwell Motors to develop a unique 3D printed copper e-winding design for the latter’s axial flux electric motors.

Elsewhere, Sintavia, an additive manufacturing service provider for the aerospace sector, has previously developed a proprietary 3D printing process for copper alloy. Developed specifically for GRCop-42, a NASA-developed copper alloy created for the 3D printing of rocket propulsion components, the technology includes both a proprietary set of 3D printing parameters and a novel heat treatment post-processing step.

Last year, industrial 3D printer manufacturer Digital Metal also announced the launch of its own pure copper powder, DM Cu, for use with its binder jet 3D printing technology.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Alloyed’s 3D printed copper cooling plate. Photo via Alloyed.