China-based additive manufacturing service provider IN3DTEC was founded in 2014, with factories in Suzhou, Shenzhen, and Shanghai. Progressing over the years, the company launched its online 3D printing service last year, which included DMLS, SLM, SLS, SLA, FDM, and MJF, which hit the news for its low-cost and industrial-grade 3D printing.

With over 300 pieces of equipment, its online digital management system provides consumers with an immediate 3D printing quote in seconds. According to the company, it can produce 3D prints in as little as one day. IN3DTEC offers various solutions for several applications, including implants and dental from medical, housing, and gears for automotive, tubes for oil & gas, impellers, and lattice structures for transportation, and aerospace, with ISO standard quality assurance on metal prints.

“We shipped parts to over 65 countries worldwide, cooperating with thousands of big names such as Leica, Danfoss, MIT, and more, with a high customer review of 4.8/5,” said Lukas Wang, the COO of IN3DTEC.

IN3DTEC’s technology portfolio includes industrial 3D printing, CNC Machining, Vacuum Casting, Injection Molding, Sheet Metal Fabrication, Die Casting, and other manufacturing services. Wang described how IN3DTEC’s 3D printing business has expanded at a 50% annual rate, making it a crucial component of its one-stop manufacturing services. Wang added, “It is great that the 3D printing market is snowballing. Four years ago, when we delivered the first metal oil tube to our customers in Europe, we were greatly encouraged by the customers’ compliments for our quality.”

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people,” said Luis Ford at Leica Medical Product Design Team.

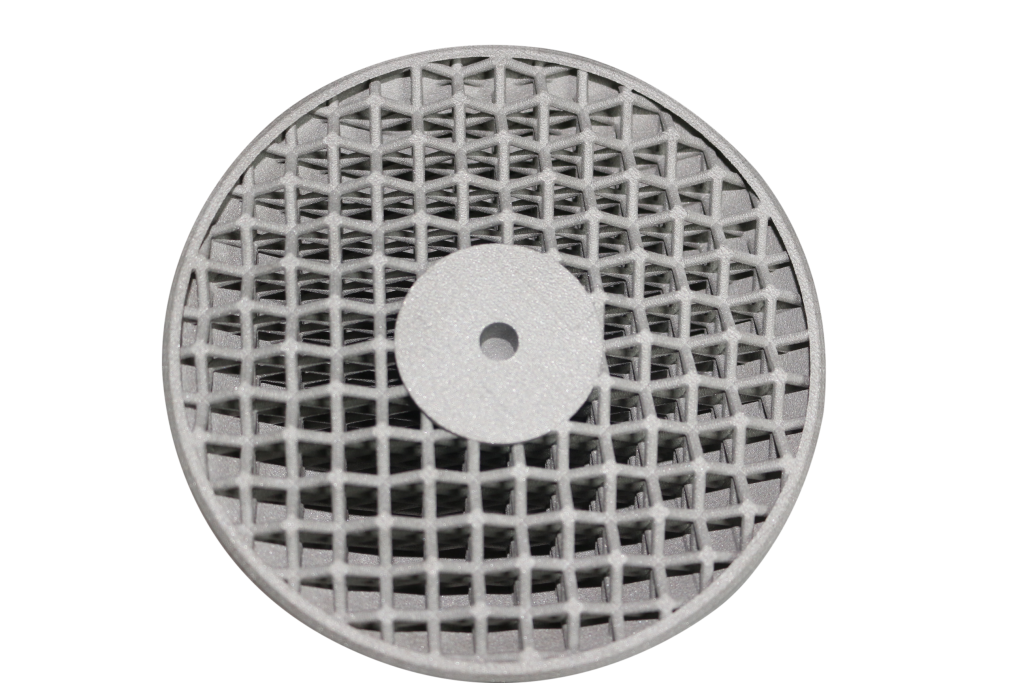

Previously, IN3DTEC grew to become one of APAC’s largest metal 3D printing service providers. IN3DTEC has many manufacturing facilities in China and offers a wide range of metals and surface finishes. The materials and surface finishes entail a large product line for both metals and plastics. Metals include Aluminum(AlSi10Mg), Titanium(Ti64, Ti64-Medical), 316L Steel, Nickel Alloy, Maraging Steel, and Co_Cr. Whereas, surface finishes of metal contain Sandblasted, Glass bead blasting, Polishing, and Painting. IN3DTEC’s plastics include Nylon6, Nylon11, Nylon12, Nylon+Glass fiber, Flame retardant PC, ULTEM9085, ULTEM1010, PEEK, PEKK, PEEK+GF, PEEK+CF, PC, ABS, PETG, ASA, and more. On the other hand, surface finishes of plastics include Polishing, Painting, Plating, Metal inserts, Vaporfuse smoothing, Water-proof, and more.

Furthermore, the company launched a new business plan called “startups metal prints,” which aims to assist more small and medium-sized businesses in accelerating the R&D process and bringing new products to market in a timely and cost-effective manner.

“3D Printing can’t be bypassed when talking about industry 4.0. It has already become an unstoppable trend for making prototypes and low-volume production,” added IN3DTEC’s COO.

Potential customers can request a quote from the company to gain more insights about its 3D printing services.

Featured image shows a satin surface finish 3D printed with SLM. Photo via IN3DTEC.