Spanish aerospace composite specialist IDEC and German advanced prototyping service provider, Wehl & Partner, have employed the use of a Stratasys 3D printer in a government-funded project exploring the capabilities of Resin Transfer Molding (RTM) technology in aerospace parts.

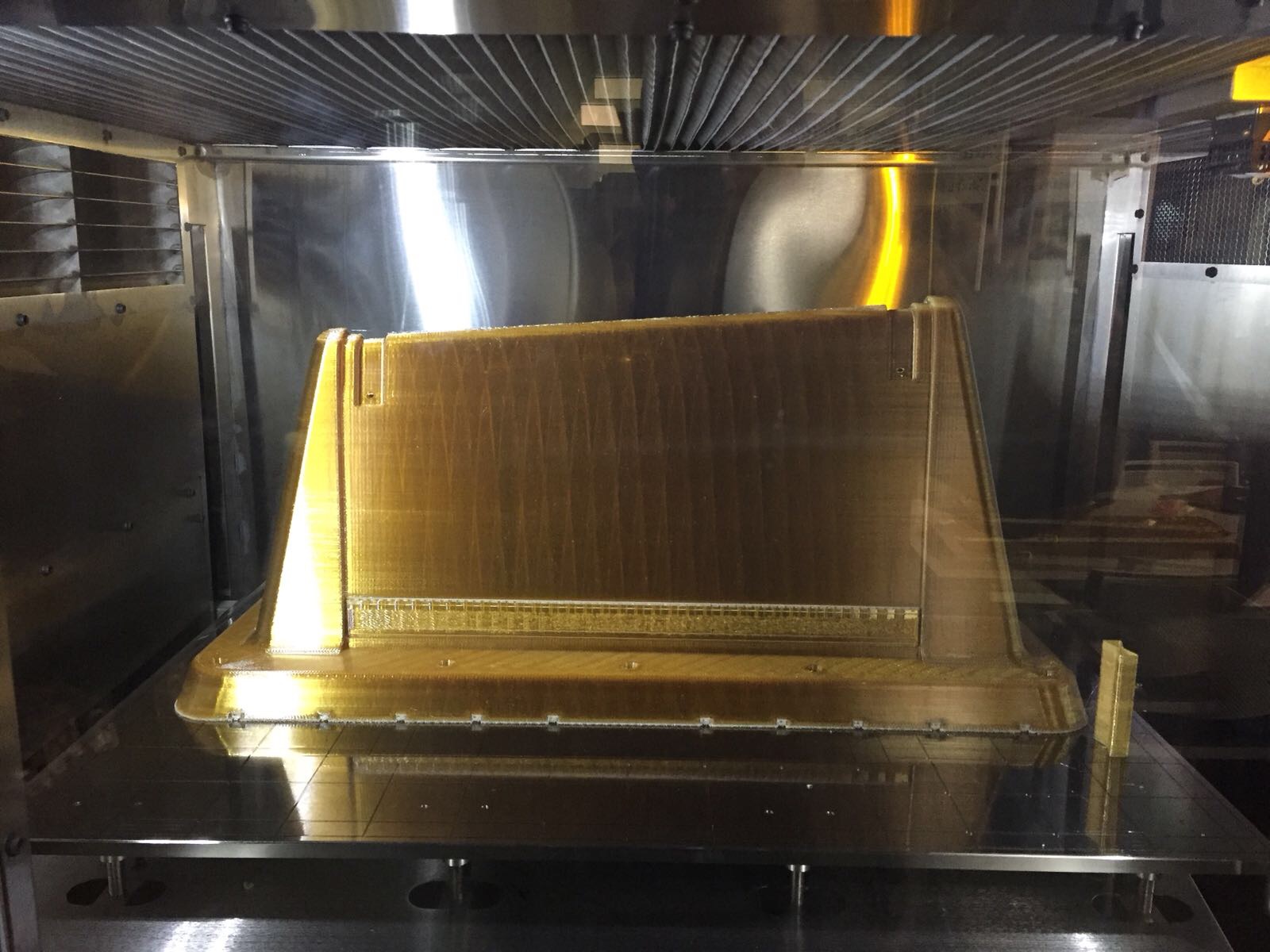

The goal of the project is to cut the time, cost and material waste involved with traditional composite molding. IDEC focused on the testing of a new composite material, investigating the molding process for the manufacture of a curved aircraft wing using RTM. Wehl & Partner used its Stratasys 3D printer, supplied by Stratasys’ Spanish distributor, Pixel Sistemas, to help IDEC manufacture a preform tool with specific properties and increased efficiency, saving the company time.

“Stratasys additive manufacturing enabled us to produce the preform tool in just 60 hours. With CNC machining, it would have taken at least four weeks to produce this type of part,” explained Diego Calderón, Structural Analysis Manager at IDEC.

“Indeed, not only did we slash the production lead-time on the preform tool, but we also expedited the whole composite molding process.”

High pressure and heat-resistant preform tool

RTM is a method for the mass production of composite parts, primarily used to mold components with large surface areas, and is often used in the automotive, industrial equipment and agriculture industries. It requires the use of a preform tool, molded in the shape of the finished product, into which resin is injected. Preform tools are placed into a mold cavity in the shape of the desired part, where it enables a composite lay-up process, with the tool then heated to take the shape of the mold. They are typically made with aluminum or epoxy resin.

However, IDEC faced an obstacle in producing the aircraft wing using RTM technology as they required a material with increased resistance to heat and pressure compared to aluminum and epoxy resins. IDEC also needed the actual composite material itself to be heated using an electric current transmitted through the composite fiber. Aluminum is a highly conductive metal that would prevent the electric current from travelling through the fiber effectively. Furthermore, standard epoxy materials available at IDEC did not have the required properties for the unusual application involving the electric current, as it needed to withstand temperatures exceeding 140°C.

Calderón commented “This project required high temperatures of between 150°C and 180°C to heat the fabrics directly, which made Stratasys FDM additive manufacturing and the use of ULTEM™ 1010 resin, in particular, the perfect choice. Although there are epoxy resins resistant to such high temperatures, these are very expensive, and would not have been financially viable.”

Wehl & Partner helped IDEC by using its Stratasys F900 Production System in tandem with the industrial-grade ULTEM 1010 material, a non-conductive and highly-resistant resin, to 3D print a large-scale preform tool. ULTEM 1010 maintains high chemical and heat-resistance, which made it a perfect fit for this specific preform tool, as it was able to withstand temperatures exceeding 150°C. The result was a preform tool with the required mechanical properties to be used in the RTM project.

Calderón added:

“In fact, with ULTEM™ 1010 resin, we reduced the composite heating stage from one hour to only ten minutes by flowing the electrical current directly through composite fabrics. This would simply not have been possible without Stratasys FDM additive manufacturing.”

ULTEM resin conducive to success in aerospace

IDEC and Wehl & Partner are not alone in utilizing ULTEM 3D printing material for manufacturing parts in the aerospace industry. Finnish airline Finnair partnered with Belgium 3D printing service provider Materialise to manufacture cabin spacer panels using ULTEM material.

Furthermore, French aviation company Airbus has standardized the use of ULTEM 9085 3D printing material for use in its A350 XWB aircraft, using Stratasys 3D printers.

In order to promote the usage of ULTEM 9085 in the 3D printing of interior components for aircrafts, Stratasys recently produced a comprehensive guide on the engineering-grade resin with Ohio-based 3D printing service bureau Rapid Prototype+Manufacturing.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the preform tool produced with the Stratasys F900 Production System using ULTEM™ 1010 resin. Photo via Stratasys.