Global chemical manufacturer Huntsman has launched a new range of materials specifically for 3D printing.

Marketed under the IROPRINT name, Huntsman’s new materials are available for SLA, HSS and FFF technologies. Each one has been developed in collaboration with end-users and market leaders, with a particular focus on footwear and sports industries. According to Stephane Peysson, Global Business Development Manager at Huntsman Polyurethanes, the new IROPRINT portfolio “fills a gap that exists for a range of functional, durable, yet softer 3D printing materials, which are technology agnostic, and both economical and easy to print – whatever your preferred production technique.”

“Ahead of the launch of the range, we’ve been building relationships with key technology partners, which in turn work with some of the biggest footwear brands in the world,” Peysson added.

“Further down the line we see huge opportunities for our IROPRINT® additive manufacturing materials in other sectors of the 3D printing market, from components for the automotive industry to objects for Internet of Things (IoT) applications.”

Huntsman’s 3D printing history

Founded in 1970, Huntsman produces a wide range of chemical products for industrial and consumer sectors. It operates across 75 sites in approximately 30 countries around the world, and employs around 10,000 associates.

As a leading manufacturer in this area, the company’s history with 3D printing long predates this most recent release. As part of its Advanced Materials division, Huntsman used to have the RenShape stereolithgraphy resin and its Digitalis laser-based rapid manufacturing technology. Both of these assets were sold by the company in November 2011 to 3D Systems Corp. for the value of $41 million, allowing Huntsman to focus on other “core competitive and strategic strengths.”

The company also has an existing relationship with Under Armour, a sports brand that has since gone on to launch a part-3D printed shoe with leading German OEM EOS.

Huntsman IROPRINT materials

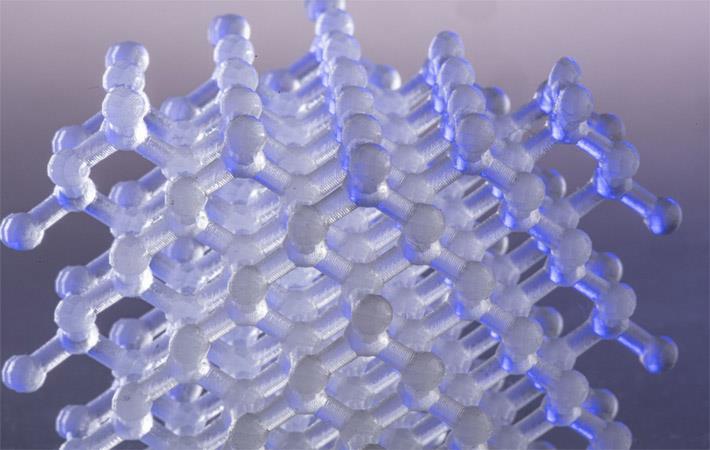

With plans to expand in the near future, the Huntsman IROPRINT range currently encompasses three product lines:

– IROPRINT R resins for vat polymerization methods such as SLA and SLP

– IROPRINT P powders seemingly specifically for high speed sintering (HSS) as applied by voxeljet and Xaar, and,

– IROPRINT F filaments for FFF

Both IROPRINT P and IROPRINT F materials consist, at present, of flexible TPU formulations as used for the fabrication of midsoles and other sports equipment.

The first public preview of the IROPRINT range will be at the K Trade Fair for plastics and rubber from 16 – 23 October 2019 in Düsseldorf, Germany.

On its re-entry into this strategic market Peysson concludes, “It is an incredibly exciting time to be in the additive manufacturing market, with estimates suggesting the sector is set to grow by more than 20% by 2024.”

In addition, he said, “We look forward to discussing the launch of our IROPRINT® additive manufacturing platform with anyone actively involved in 3D printing at the main K show in October.”

For all the latest additive manufacturing materials and business news subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

Visit 3D Printing Jobs to find new opportunities in additive manufacturing.

Featured image shows Stephane Peysson, Global Business Development Manager at Huntsman Polyurethanes announces the New ISOPRINT range at the K Show preview. Photo via Plastics Tech Mexico