Today, two years after the launch of the Replicator +, American desktop 3D printer manufacturer and Stratasys subsidiary MakerBot has released the Method. Designed as a mid-way point between the industrial FDM and personal desktop market, MakerBot is calling the Method “the first performance 3D printer.”

Last week, 3D Printing Industry was invited to MakerBot HQ in Brooklyn, NY, ahead of the public launch to speak with the company’s President and CEO, Nadav Goshen, and Forrest Leighton, VP of Marketing.

A strong front in the face of the company’s return with a new product, Goshen explains how, with the Method, MakerBot is looking to “rebuild its core competence” and boost its presence within the engineering sphere.

Eradicating the ‘go figure’ approach

MakerBot’s foundations were, of course, established through the maker movement. In machines made for this market, there is always a willing participation element in the 3D printing process, as Goshen describes “[Operators] find themselves working for the 3D printer […] Up until now [3D printer development] was a refinement of the first RepRap.”

With the Method, however, he adds:

“We stop the ‘go figure’ approach.”

Through analyzing the market, in its transitional phase MakerBot identified “hobbyist, consumers, professional and education” as the four key areas of 3D printing application. Under the direction of Goshen, and inline with Stratasys, the company has selected two of these areas to pursue with the Method, namely “professional” and “education.”

At this point the company also faced a decision. “We could not unlock the professional market with the current desktop 3D printers,” Goshen adds, “including our own.”

And so, “We thought differently. We thought, what are the minimum specifications that you want to have in the professional market, and then, what is the lowest price you can get?”

MakerBot Method technical specifications

The Method 3D printer is a dual extrusion FDM 3D printer, relying on one nozzle to print soluble supports, and the other to make the object. It has a circulated heat chamber to help with the layer adhesion and overall quality of 3D printed objects. To boost the speed, and reportedly “print up to 2X faster” than other desktop material-extrusion 3D printers, each of the Method’s extruders include heaters with higher processing rates compared to the company’s existing systems.

With single extrusion, the Method has a max build volume of 19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in. With dual extrusion, this volume is shrunk to 15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in.

MakerBot’s operating software for the Method allows the user to 3D print in one of three possible, and automated, modes: Draft, Balanced and Minfill (i.e. hollow.) All objects shown at the press preview day were 3D printed with in Balance mode, providing a good, smooth surface finish.

Other key features of the 3D printer include an ultra-rigid metal frame body, for a more stable print, dry-sealed material bays, and readable RFID chips on the spools, to feedback real-time usage and moisture data, read and delivered in real-time by the 3D printer through its integrated touch screen. The 5″ user interface also includes animations to aid the user in performing operations and the 3D printer’s general setup.

In the presentation of the machine, user friendliness was one of the key takeaways from the press event last week. From the demonstration, the Method certainly looks like it would operate with a smoothness on-par with a common paper printer. And this, in many ways, is what MakerBot is trying to achieve.

Method availability

The Method 3D printer is now available for preorder directly through MakerBot, with shipping to begin in the first quarter of 2019. Presently, the company is also looking for on-board partners to offer the system in different companies around the world.

As of now, the machine has been in beta testing for 1 year with between 20 and 50 trusted customers including a handful of research institutions, small consumer electronics companies and, according to Leighton, “all the biggest brands.”

At present, though the Method is an open materials platform, PLA and PVA are the only official materials released by MakerBot for use with the machine. In the near future, the company plans to expand this material availability, along with further operation modes and extruders.

Making bold claims in the closing comments of the press preview at Makerbot HQ, Goshen said “I think every engineer should have three things beside them: a pencil, CAD software and the Method.”

Nominate your 3D printer of the year in the 2019 3D Printing Industry awards now.

To stay up-to-date with all the latest news and 3D printer releases subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking new opportunities in this rapidly growing industry? Sign up to 3D Printing Jobs.

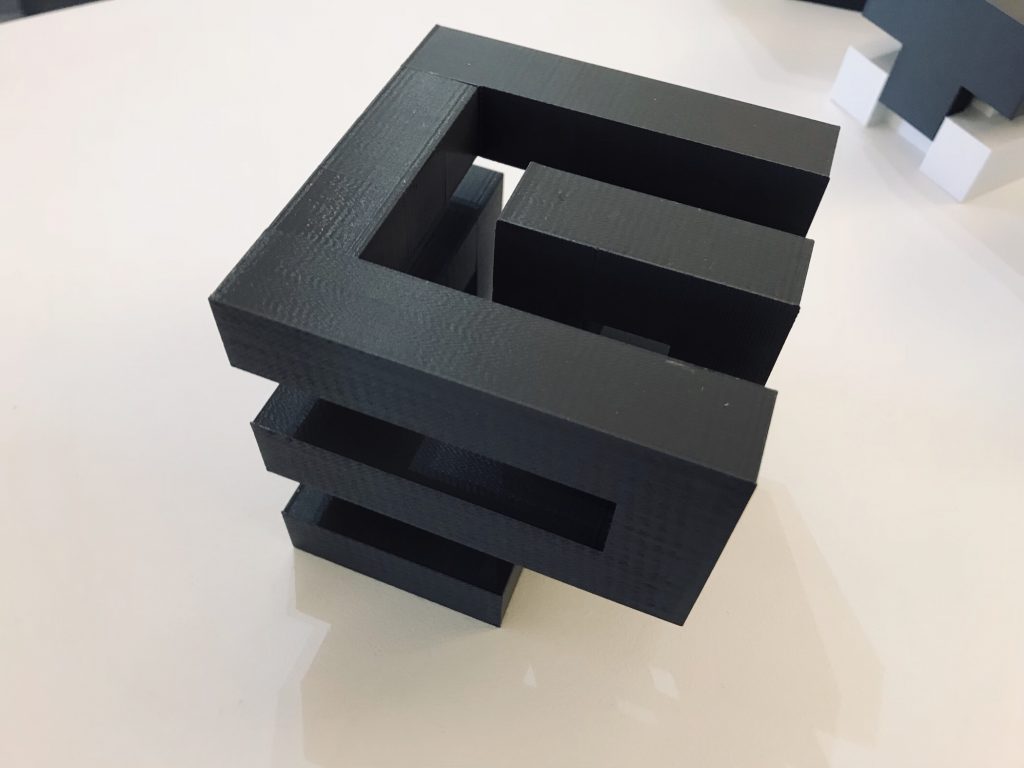

Featured image shows a closeup of the MakerBot Method 3D printer. Photo by Beau Jackson