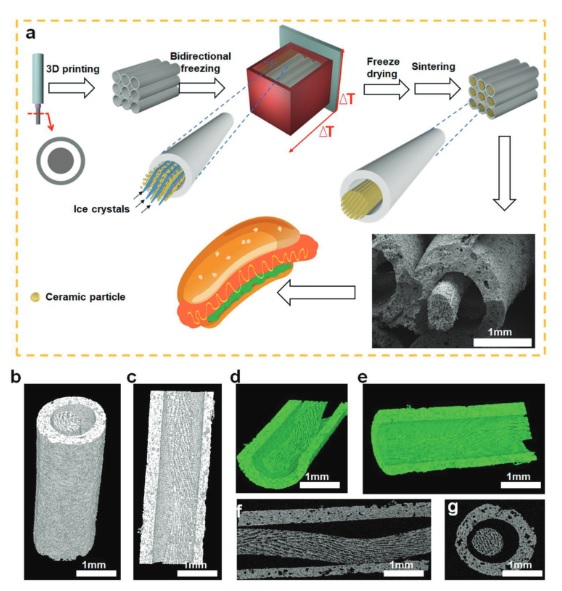

Researchers at the Shanghai Institute of Ceramics, Chinese Academy of Sciences (SICCAS) have created a 3D printable material for use in cell scaffold fabrication. Taking inspiration from an unlikely source, the team’s development is likened to the structure of hot dogs…

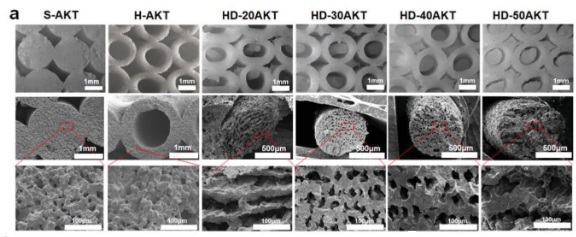

“The scaffolds are composed of hollow bioceramic tubes (mimicking the “bread” in hot dogs, pore size: ≈1 mm)” describes the Advanced Science study, “embedded by bioceramic rods (mimicking the “sausage” in hot dogs, diameter: ≈500 µm).”

Put to the test, the hotdog biomaterials, referred to as HD-AKT, have shown “excellent properties for loading and releasing drugs and proteins.” Scaffolds made from the materials have also proven potential to improve the delivery and differentiation of tissue cells.

Bread and structure

According to the SICCAS team, micro/nanoscale hierarchical structures have great influence on material properties. Human bones maintain natural hierarchical structures which enable the transportation and storage of the nutrients and tissue cells.

“However, conventional 3D printed scaffolds composed of the stacked solid struts lack […] hierarchical structures,” the co-authors state, this therefore limits the delivery of adequate nutrition to developing tissue cells, “further affecting,” they add, “the tissue formation in the inner of large bone defects.”

As a popular food, the researchers were influenced by hot dogs which supply energy and nutrients using a bread and sausage. Turning the structure into a practical formation for a biomaterial, HD-AKT was fabricated using direct ink writing and bidirectional freezing.

Through freeze-casting, the microscale HD-AKT properties, which possess uniformly aligned lamellar micropores (≈30 µm) in the sausage-like bioceramic rods, can be controlled.

Hot dog and bone regeneration

HD-AKT were implanted in femoral defects of rabbits at 8 weeks to test effectiveness. Newly formed bone grew into the hierarchical rods of the scaffolds, proving the potential for new bone regeneration.

The scaffolds exhibited improved specific surface area, which significantly enhanced the drug/protein delivery, cell proliferation, and osteogenic differentiation of rabbit bone marrow stem cells.

“[Our] in vivo study further demonstrates that both the hierarchical structure itself and the controlled drug delivery in hot dog-like scaffolds significantly contribute to the improved bone-forming bioactivity.”

“3D Printing of Hot Dog‐Like Biomaterials with Hierarchical Architecture and Distinct Bioactivity” is co-authored by Tian Li, Dong Zhai, Bing Ma, Jianmin Xue, Pengyu Zhao, Jiang Chang, Michael Gelinsky and Chengtie Wu.

Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook for more additive manufacturing news.

Join our 3D Printing Jobs to post a job or advance your career in 3D printing now.

Featured image shows 2D micro-CT images of HD-AKT from different views showing the scaffold structures. Image via SICCAS.