Germany’s Fraunhofer Institute for Laser Technology (ILT) and RWTH Aachen University have won an award for development of Extreme High-Speed Laser Material Deposition (EHLA).

In place since 2000, the Berthold Leibinger Innovationspreis is one of the most prestigious awards in laser technology, and is presented every two years by a panel of experts from science and industry.

Stressing the importance of this accolade, Thomas Schopphoven, head of the Productivity and Systems Engineering team in the Laser Material Deposition Group at Fraunhofer ILT, says, “[…] this is one of the world’s top-class awards,”

“We are extremely pleased about the recognition of our work on energy- and resource-efficient production with laser light.”

Inside Extreme High-Speed Laser Material Deposition

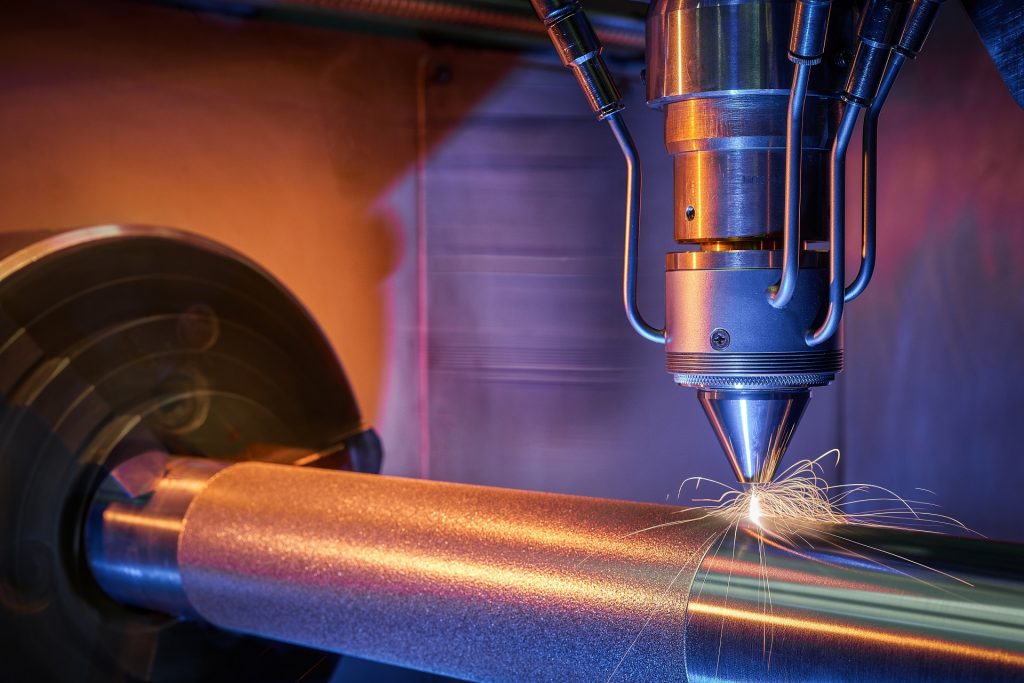

As the name suggests, EHLA is a technique based on common laser metal deposition (LMD) technology. In place of a powder bed however, EHLA blows powder directly into the laser beam, meaning that it can deposit freshly melted metal onto a variety of pre-made substrates.

This direct approach to powder melting is also what achieves the technique’s high speed. On average, EHLA can 3D up to 500 m/min, rather than the LMD standard of print a few meters per minute. In addition, EHLA is capable of achieving a layer thickness in the range of 10 to 250 μm, as opposed to typical thickness of 500 μm.

Commercial availability

EHLA has found use as an alternative means of high speed coating for metal components. In China, Fraunhofer/Aachen EHLA systems are being sold through ACunity GmbH which recently confirmed the delivery of three machines to service provider Hebei Jingye Additive Manufacturing Technology Co.

Schopphoven asserts that “The EHLA process is particularly suitable for the automotive industry, such as for the coating of brake discs, which were previously difficult to coat because of the high loads and high demands on efficiency and environmental friendliness.”

The Aerosol Jet Print Engine from Mew Mexico machinery company Optomec, is another metal deposition technique working in the area of coatings, particularly for electronic components.

Fraunhofer ILT is also home to the Future Additive Manufacturing (futureAM) project seeking “to significantly accelerate” and reduce the cost of metal 3D printing.

Stay up to date with the latest 3D printing developments – sign up to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Get involved with 3D printing events near you here.

Featured image shows the EHLA Process. Photo via Fraunhofer ILT.