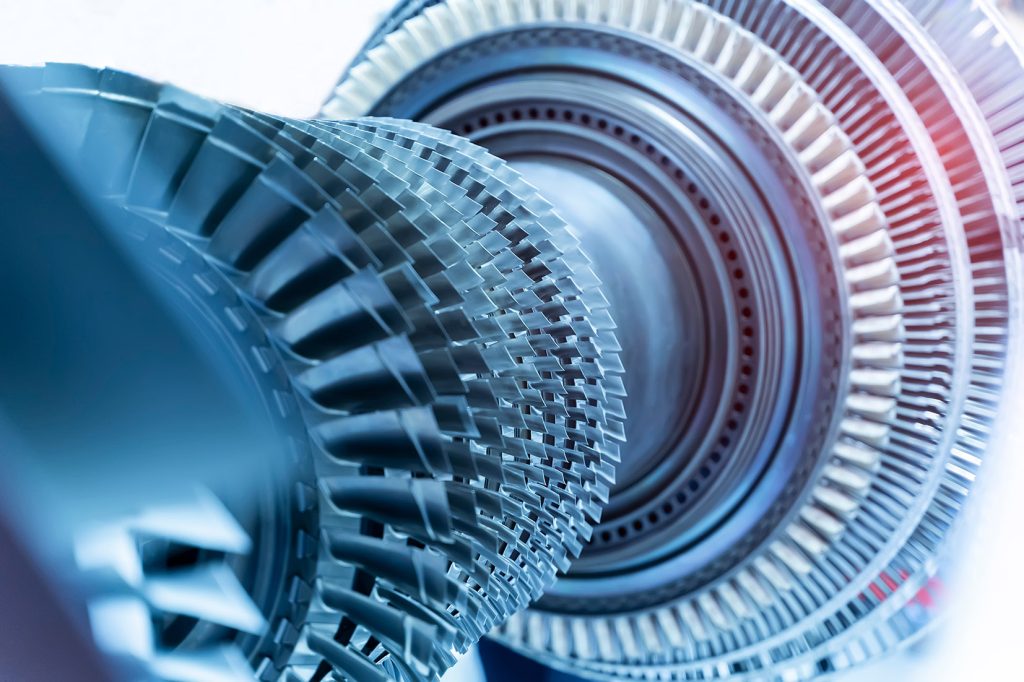

Goodfellow Cambridge Ltd. has announced customized metal alloy powders for additive manufacturing (AM).

The Huntingdon, UK, company that makes specialty metals and materials expects significant interest from AM companies, enterprises that build jet engine structures, store hydrogen, or make medical implants. The manufacturer aims to generate additional sales of over £500,000 from the launch.

“Additive manufacturing has the potential to be a significant market for our business. This is because high-end technological systems increasingly demand lightweight and intricate components, which can be produced more efficiently and with less material waste using 3D printing,” said Goodfellow’s Head of Technical Aphrodite Tomou.

The new customized alloy powders will also feature High-Entropy Alloys (HEAs) with qualities essential for future material breakthroughs, allowing for improved composition, particle size, and batch number flexibility. Goodfellow says their metal powders have excellent resistance to corrosion, fatigue, fracture, and irradiation. They also have strong thermal stability, ductility, and magnetic properties.

Tomou explained that Goodfellow can make a HEA using practically any combination of materials, which offers enormous possibilities for breakthroughs in industrial design and the manufacture of 3D printed components.

“Thanks to our long-standing relationships with several specialist partners, we are the only UK supplier of customized alloy powders and are already working with designers and engineers to help them unlock experimental and production benefits. “This is an exciting introduction,” said Tomou.

Goodfellow employs over a hundred people at its Ermine Business Park location. Using ultrasonic technology, it makes cutting-edge alloy powders with a high sphericity of 0.98 and a narrow particle size distribution. The company has a six-person technical staff that can advise on the different mixtures needed for different uses. It can deliver metal powders in quantities as small as 100 g to encourage creativity and R&D.

“This new form of technology is already taking the weight out of parts destined for airplanes and rockets, whilst, in the medical industry, it will increasingly be used in customised implants and prosthetics,” said Goodfellow’s Head of Technical. “It is also a rapidly evolving field and there are many exciting developments on the horizon. For example, researchers are working on new materials that can be 3D printed, such as graphene, nanodiamonds and carbon fibre composites that open up unique properties and new possibilities.”

Goodfellow provides a full spectrum of custom processing services, functioning as an extension of a client’s manufacturing team to manufacture custom-fabricated components in any quantity.

Advancing Metal Powders for Additive Manufacturing

Research from the Ecole de Technologie Superieure has proposed a new Additive Manufacturing Suitability (AMS) factor to rank the printability of metal powders for Laser Powder Bed Fusion (LPBF) processes. The AMS factor can differentiate printability in a way that conventional powder testers cannot, as it combines the dynamic, shear, and bulk properties of powders into a single metric.

To measure the properties of the powders, both sets of researchers used the FT4 Powder Rheometer from Freeman Technology. The researchers hope that the AMS factor will help the AM community, from powder and machine suppliers to end-users, to reliably test a powder for printability. Freeman Technology’s Operations Director, Jamie Clayton, said that this research demonstrates progress toward this goal, an emerging consensus on the need to measure multiple parameters and the value of dynamic flow properties. This development could improve the quality and reliability of powder for metal additive manufacturing.

Tekna, a leading supplier of advanced materials to industry, recently announced that its partnership with Uniformity Labs would be expanded to include the supply of an AlSi10Mg aluminum alloy. The alloy will be used to make AlSi10Mg metal 3D printing powder for Laser Powder Bed Fusion 3D printing systems. The partnership with Tekna demonstrates how advanced technology can improve sustainability for various industries, said Adam Hopkins, founder, and CEO of Uniformity Labs.

This partnership lets Tekna improve the amount of powder it makes, which Uniformity will use to make better powders for LPBF. Compared to competitors, Uniformity says its method makes powder production more efficient, so more than 95% of the powder can be used. This cuts costs and boosts capacity, which makes manufacturing more efficient and helps meet sustainability goals for both traditional and additive manufacturing. The companies will collaborate to assist industrial clients in producing cleaner, more sustainable parts in industries such as aerospace, transportation, energy, defense, and medical, without sacrificing quality.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image via Goodfellow Cambridge.