Additive manufacturing software provider Gravity Pull Systems has launched a comprehensive workflow optimization system for industrial 3D printing.

Dubbed Synoptik, the AI-based software is aimed at service bureaus and manufacturing companies serving a wide variety of industries such as aerospace, medical and automotive. By providing optimization operations for every step of the 3D printing workflow, from pre-processing to post-processing and quality inspection, Synoptik is intended to fill every niche there is.

End to end production scheduling

Synoptik’s core functionality is in its Scheduling Optimizer and Manufacturing Execution System (MES), whereby the software offers to handle all of the logistical aspects of a manufacturing facility or print farm at the click of a button.

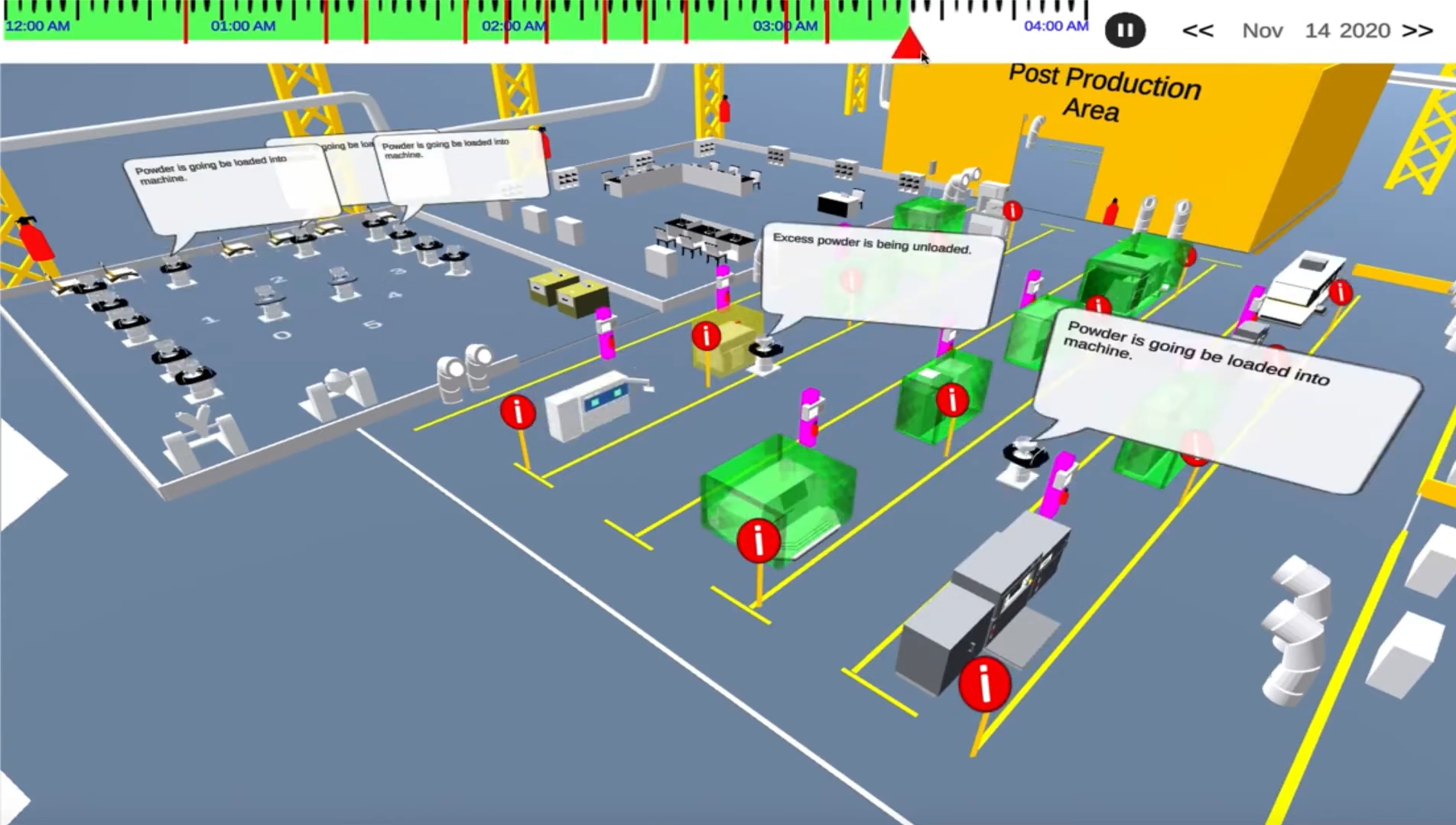

Once the user inputs which parts they would like printed, along with what 3D printers are currently operational on the shop floor, the software automatically calculates a number of optimal workflow scenarios to choose from. These can all be viewed in a virtual 3D space depicting the manufacturing facility, providing users with a visual representation of their own potential workflows.

On the engineering level, it can give recommendations on the nesting of the build plates and process parameters, while on the operational level, Synoptik can recommend which printers would best be suited for which parts and in what order. For each scenario, the software outlines key parameters such as the expected production time, expected costs, and expected material consumption, enabling manufacturers to make more informed choices. Since the software also takes into consideration post-processing and quality inspection, these stages are also accounted for when calculating parameters like the unit-cost of a part.

Dynamic reconfiguration via AI

Owing to the machine learning-based numerical models driving the software, Synoptik can also make automatic dynamic workflow changes on the fly. The software is able to reconfigure the order of print jobs when new urgent order requests are raised, ensuring the user is constantly benefiting from reduced manufacturing costs, minimal material consumption, and maximum capacity utilization on a rolling basis.

The software also allows for process parameters to be modified in real-time with continuous ‘Track & Trace’ process monitoring, which gives users the power of full traceability. As such, the entire manufacturing process can be made to meet the strict compliance requirements of highly regulated industries such as aerospace.

In terms of bonus features, Synoptik even provides a simulation feature allowing users to test various ‘what if’ scenarios. This includes unforeseen changes in part demand from a client or an accident on the shop floor which may render a 3D printer out of operation. As for security, the software also logs sensor data in an immutable format, generating private/public keys for a number of data storage media such as blockchain automatically.

While Gravity’s system is intended as a holistic workflow optimization companion, there are a number of other more specialized workflow-related programs on the market. Software developer Authentise recently announced a partnership with Addiguru, a developer of real-time process monitoring systems, to advance the Authentise Manufacturing Execution System (AMES). Together, the duo have since been working to integrate AI-based in-situ monitoring functionality into AMES, allowing for real time actions alongside the existing digitized workflow management capabilities.

3D printer OEM Coherent and exocad, a dental CAD/CAM software developer, have also previously announced a partnership aimed at simplifying the digital workflow of dental professionals. The partners are currently developing a workflow data interface between exocad’s DentalDB software and Coherent’s DENTAL COCKPIT slicer, which will streamline the production of metal dental restorations.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Synoptik’s Scheduling Optimizer. Image via Gravity Pull Systems.