Dyndrite Corporation, a Seattle-based additive manufacturing software company, has announced that Google’s AI-focused investment fund, Gradient Ventures, will lead its $10 million Series A funding round.

Cota Capital, Amplify Ventures, the House Fund, and Carl Bass, former President and CEO of Autodesk, are also investing in this round which enables the release of software tools within the Dyndrite Accelerated Geometry Kernel.

Anna Patterson, VP of Engineering for Google and Managing Partner at Gradient Ventures, comments, “We are at a unique point in time where innovative manufacturing hardware has outpaced its software counterparts,”

“Dyndrite is a new platform that takes into account modern computer architecture, modern design needs, and modern manufacturing capabilities.”

The Dyndrite Accelerated Geometry Kernel

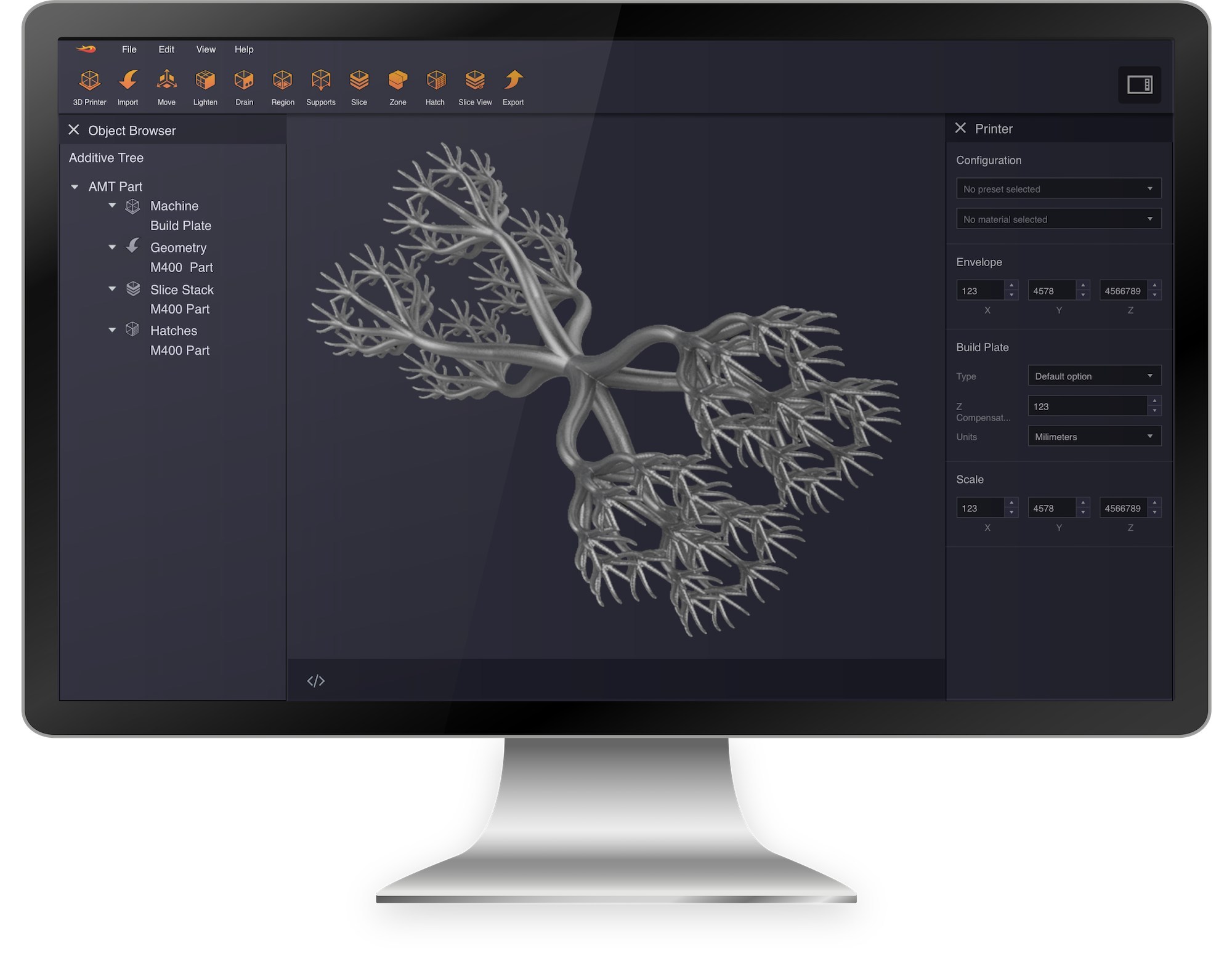

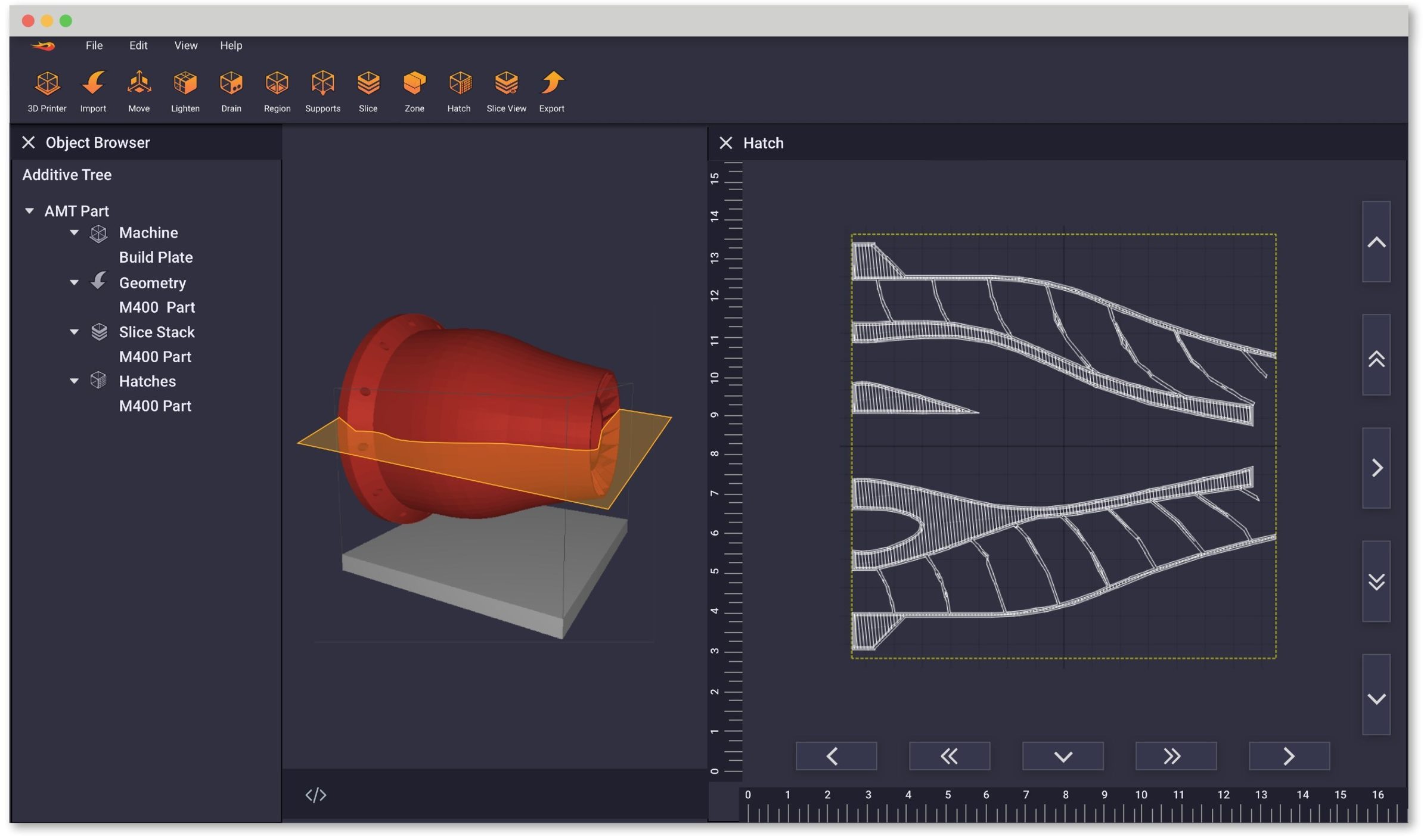

The Dyndrite Accelerated Geometry Kernel (AGK), was introduced by the company earlier this week at AMUG 2019 as the first fully Graphics Processing Unit (GPU) native geometry engine for CAD/CAM for 3D printing.

Additionally, the Dyndrite Additive Toolkit was launched as the first application built on AGK, which enables a streamlined CAD-to-Print workflow for increased productivity and efficiency in additive manufacturing processes.

“We are entering the next phase of our company and are excited to play our role in fostering the evolution of the design and manufacturing industries,” said Harshil Goel, CEO, and co-founder of Dyndrite.

“We’re proud to be a part of the aspirations of our early lighthouse customers. We look to tell our story in a broader context, inspiring and empowering those who are transforming how people design and make things to propel the human race forward.”

Closing the gap between hardware and software

The ultimate goal of Dyndrite is to close the gap between 3D printing hardware and the software in aerospace, medical, energy, and automotive applications where productivity and accuracy are crucial.

As well as developing the AGK, the $10 million in funding will enable Dyndrite to hire team members in engineering, marketing, sales, and support functions. The company expects to grow from 15 to approximately 30 employees by the end of 2019.

“With its revolutionary geometry engine and Additive Manufacturing Toolkit, Dyndrite is poised to transform additive manufacturing,” explained Bass. “It’s exciting to be a part of this disruptive step forward.”

Vote for the 2019 3D Printing Awards.

For more information on the latest trends in additive manufacturing subscribe to our 3D printing newsletter and follow us Facebook and Twitter.

Visit our 3D Printing Jobs board to find out more about opportunities in the additive manufacturing.

Featured image shows the Dyndrite Additive Toolkit within the AGK. Image via Dyndrite.