GKN Aerospace, a British aerospace supplier, has opened an aerospace-engine research and repair facility in Johor, Malaysia.

The new site will be the company’s first of its kind facility in the Asia-Pacific region, with a focus on the application of 3D printing in repair and research.

The project is a joint effort between GKN, industry partners, the Malaysian Investment Development Authority (MIDA), a government agency specializing in the manufacturing sector, and the Government of Malaysia.

CEO of GKN Aerospace Engine Systems, Joakim Andersson said: “We are proud to extend our global presence with this new site in Malaysia. This new facility highlights our commitment to support our customers in Asia. This will definitely lead to exciting growth opportunities. We thank the Government of Malaysia for the excellent collaboration and for supporting and facilitating our decision to locate in their country.”

GKN’s first aerospace engine repair facility

This year in July, GKN was present at the Farnborough Airshow with a focus on 3D printing. It was here that the company made the announcement that it will open an aerospace engine repair facility in Malaysia. Since then the aerospace company has invested $30 million in the new site and hired 15 members of staff.

By 2019 and by 2020, the Johor site will be fully operational and will grow the number of employees from 150 to 300.

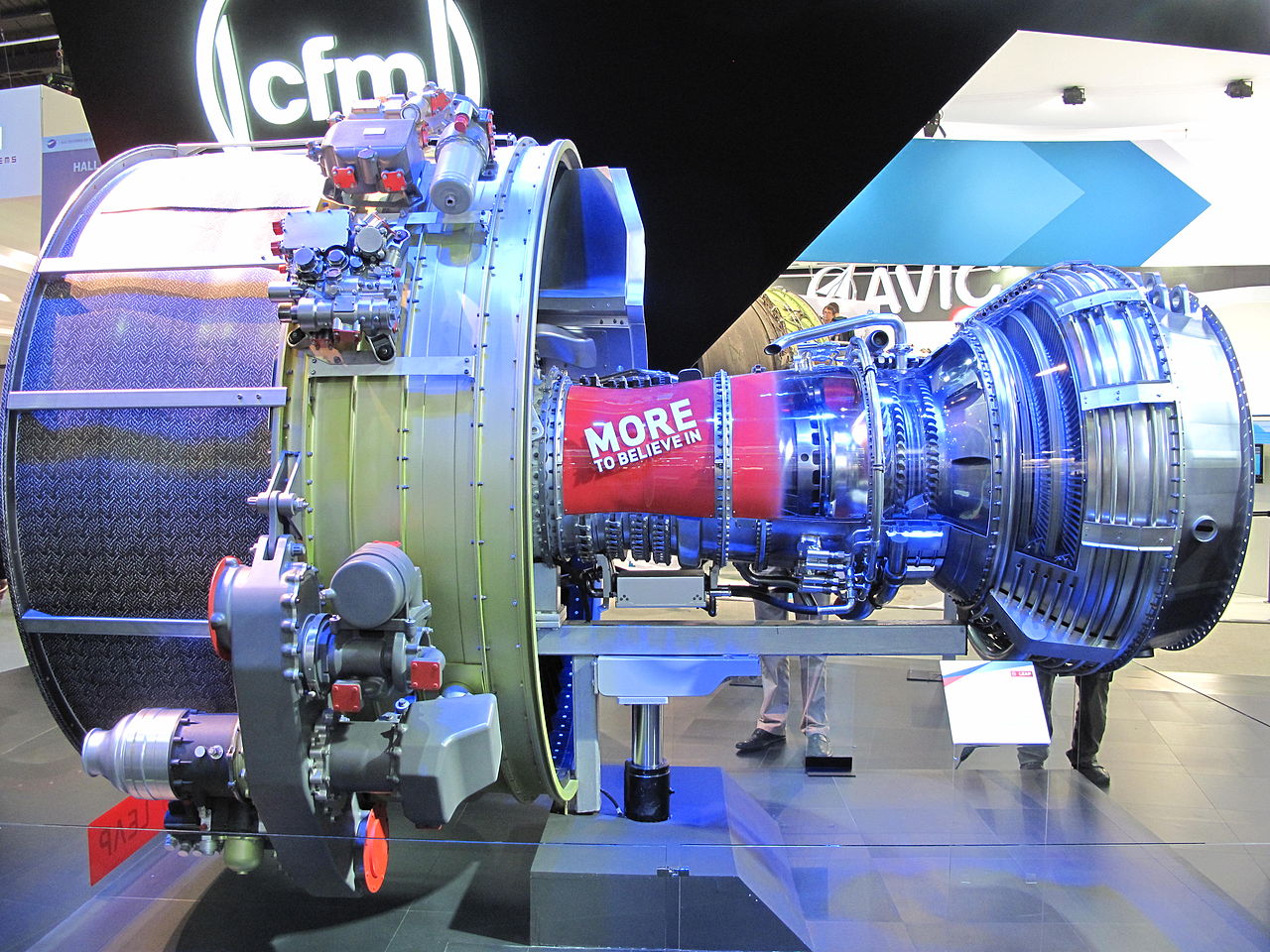

The repair facility will begin its operation with servicing high-bypass turbofan aircraft engine components. Among the company’s repair inventory will be the V2500 and the CFM56 engine, one of the first turbo engines engineered with a 3D printed fuel nozzle.

GKN currently runs six services facilities in the Asian region, including China, India, Singapore, Thailand, and Turkey. But the Malaysian site will be the first engine repair facility of the company in the region and part of its long-term plans of growth in the Asia-Pacific market.

GKN’s 3D printing expertise

Previously, GKN Aerospace has collaborated with Saab, an aerospace company, to 3D print aircraft components.

In another project, GKN partnered Oak Ridge National Laboratory (ORNL) in the U.S to manufacture large-scale 3D printed titanium parts for aerospace applications.

A similar venture brought Ariane Group and GKN together to develop two full-scale 3D printed turbines.

Subscribe to our 3D printing industry newsletter for more news on the aerospace industry. Join us on Facebook and Twitter.

To start a new career, visit our 3D printing jobs.

Featured image shows a CFM56-7B engine which powers the Boeing 737. Image via CFM