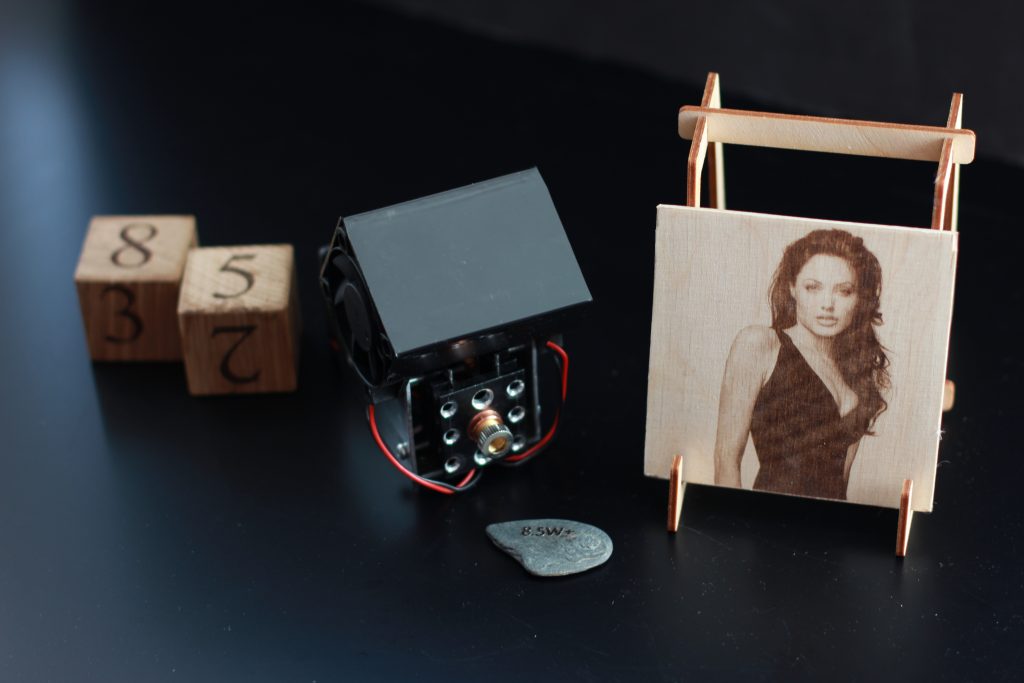

Endurance Lasers gives makers the ability to upgrade 3D printers, CNC routers and other DIY machines with multi tool functionality. By installing a laser diode, these machines become cutting tools and engravers, capable of writing on acrylic, wood, leather and metal, maximizing workshop productivity.

The lasers can be installed on any 3D printer or CNC machine to extend capabilities.

Read on for an exclusive discount.

In a series of Endurance experiments, we see how the 8.5W+ makes short work of matte & hard steel, and glossy & composite aluminum.

Optimal focus

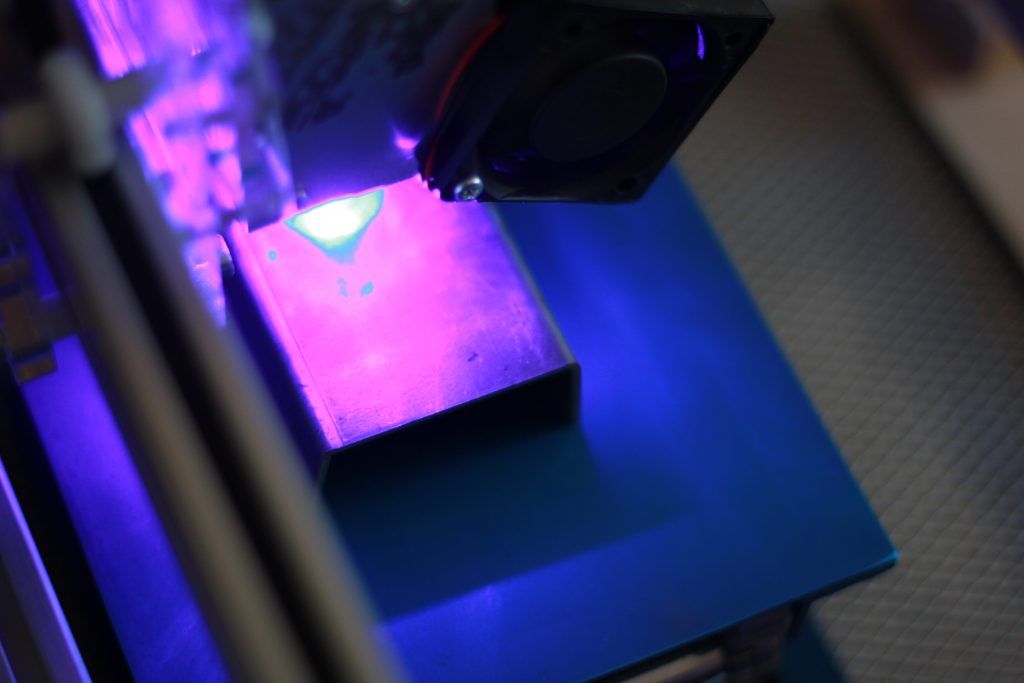

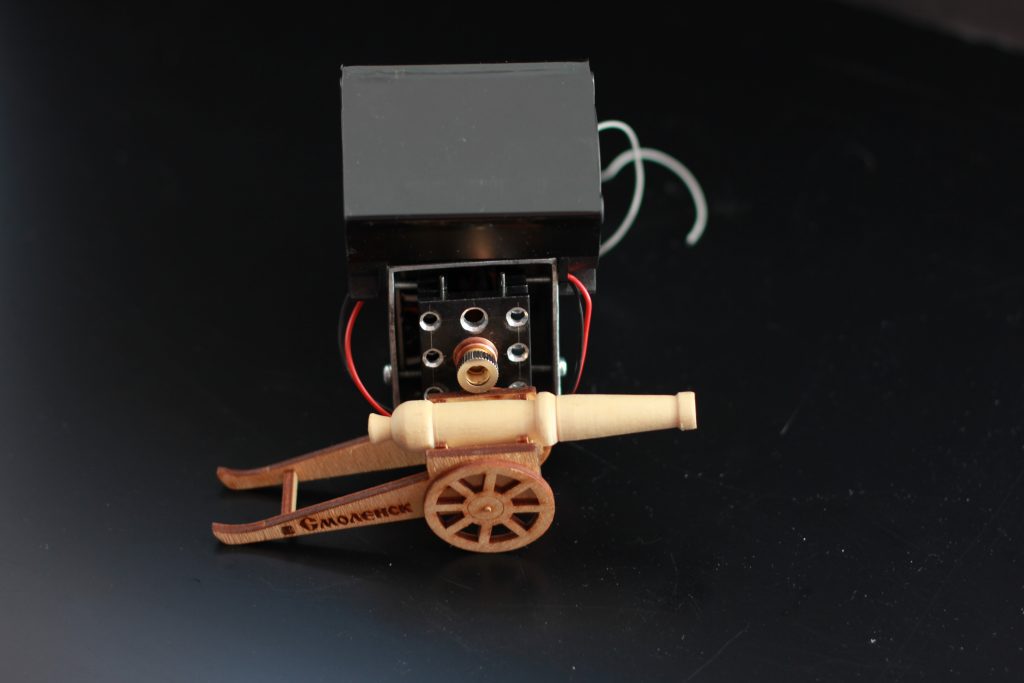

For the purpose of these experiments, the 8.5W+ laser was installed on an Endurance DIY engraving/cutting machine. As with all of Endurance’s lasers, the 8.5W+ can be easily installed on a number of desktop 3D printers.

As a preliminary test, Endurance determined the optimum focal range for its G2 focal lens.

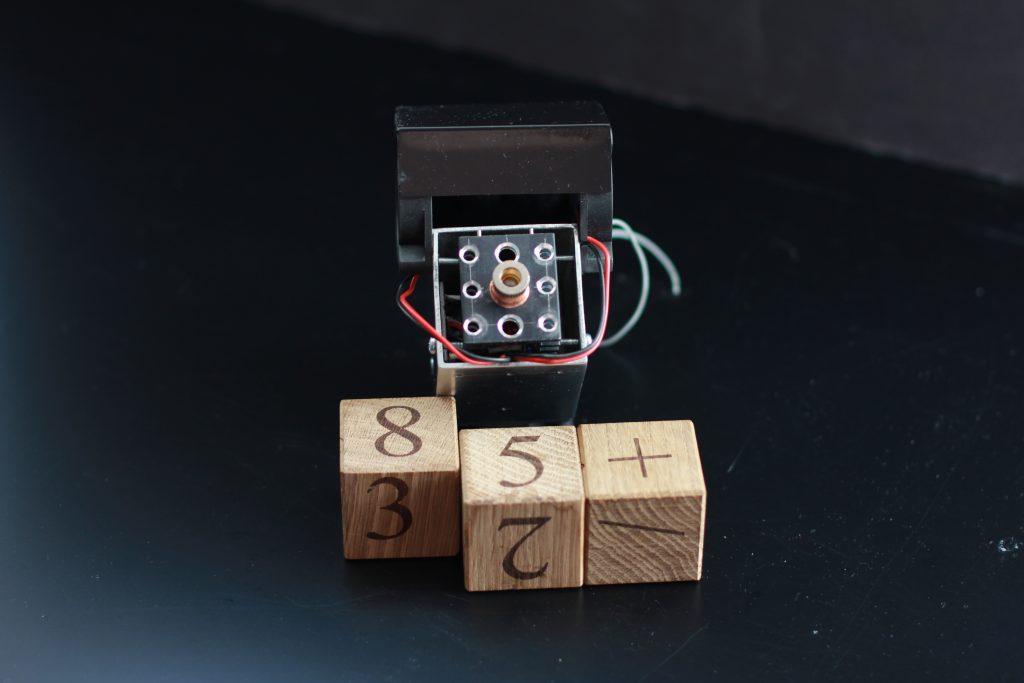

A 5 mm length piece of wood was selected as a test. At a speed of 10 mm/s the laser and lens are capable of cutting a 5 mm length in one single pass with minimal charring. It is worth noting that some engraving projects require a multiple pass of the laser. All metal experiments by the 8.5W+ below were accomplished in a single pass.

6 mm, then, is determined as the best focal range for G2 short focal lens. Verified by a simple sight test (through red or green goggles), optimum focal range is when a spot is at its minimum diameter, and achieves maximum light intensity.

Putting metal to the test

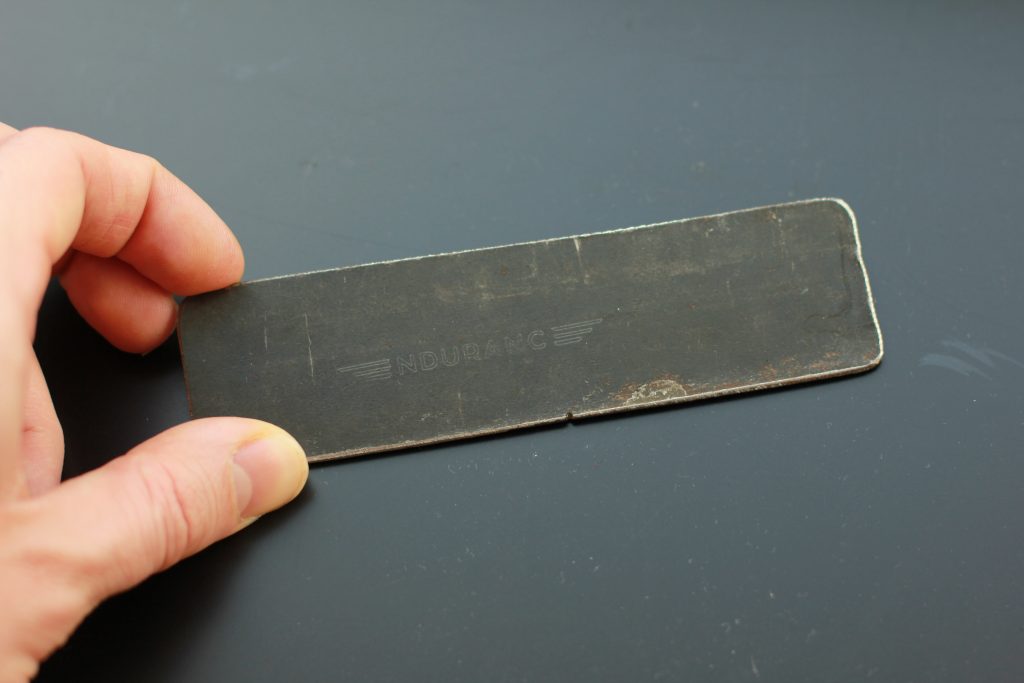

In the first experiment after the preliminary test, a rectangular plate of plain matte steel is engraved with the Endurance Laser logo. The cleanest and best result for writing the logo was a speed of 1.5 – 2.5 mm/s. At 55 mm long and 5 mm wide, the logo took 3 – 5 minutes to engrave, and was made in a single pass of the laser.

And in the final trial, the laser successfully made etchings on the surface of a hard grade steel component in 20-30 seconds at a speed of 5 -10 mm/s.

For any makers that want to pack an even bigger punch with their laser engraving and cutting capabilities, Endurance has a 10W laser capable of engraving stainless steel, copper and brass in a single pass.

The Endurance 8.5W+ laser is available as an upgrade for 3D printers and CNC routers for $695. It has a total lifetime of 10,000 hours, and continuous operation time of 48-72 hours.

If you have any questions about Endurance Lasers then Live chat is available their web site. The CEO and founder of Endurance George I Fomitchev will be happy to answer your questions.

Telegram bot: @Endurancelasers_bot

Telegram group: https://t.me/joinchat/EGsGxQkh3SAY55ZvMixySw

Telegram channel: https://t.me/Endurancelasers

Discover more of the Endurance Lasers range and buy now here.