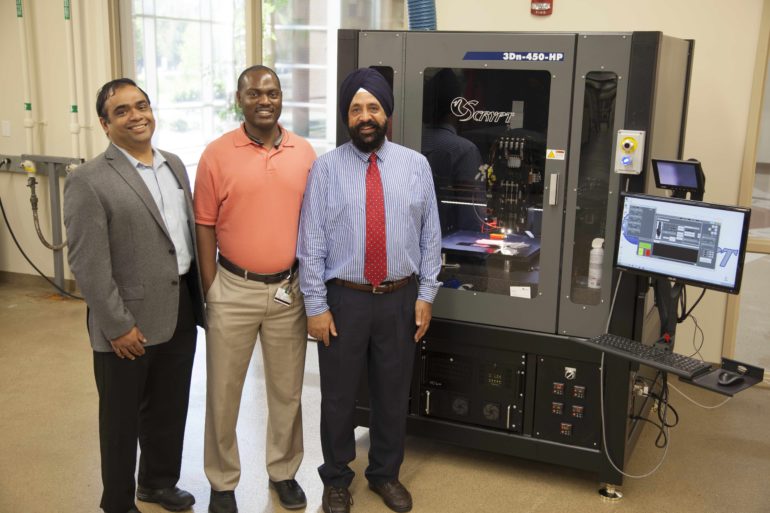

The Georgia Institute of Technology, University of Connecticut (UCONN), and the University of Massachusetts Lowell are collaborating to establish a National Science Foundation (NSF) Industry/University Cooperative Research Center (I/UCRC) for 3D printing.

The I/UCRC will operate from all three universities to form the Science of Heterogeneous Additive Printing of 3D Materials (SHAP3D) center, addressing emerging challenges in the industry.

“Our vision is to establish a synergistic national network of excellence in additive manufacturing knowledge, experience, and facilities that will add value to the additive manufacturing industry, which is expected to top $20 billion within the next five years,” said Professor Joey Mead, Distinguished University Professor at UMass Lowell and Director for SHAP3D.

3D printing and the NSF

Founded in 1950 by the U.S. Congress, the NSF acts an independent federal agency created “to promote the progress of science; to advance the national health, prosperity, and welfare.” The NSF holds an annual budget of about $7 billion, and has previously awarded Florida A&M University (FAMU) $4.9 million dollars to establish the Center for Complex Materials Design for Multidimensional Additive Processing (CoManD Center).

In recent years, the NSF has also awarded the University of Central Florida (UCF) and the University of Texas (UT) $400,049 for research developing 3D printed photon funnels. Following this, OESH shoes, an orthotic footwear company based in Charlottesville, Virginia, was awarded a phase II grant from the NSF to develop its pellet-based 3D printing process for manufacturing shoes from elastomer materials.

The SHAP3D additive ecosystem

The NSF’s new I/UCRC program focuses on collaborative, pre-competitive research forming “a financial and procedural framework that provides significant value to the nation, industry and university faculty and students.” Presently, 14 industry partners have committed to join the SHAP3D center and will provide $2.25 million in funding for projects.

Within the center of excellence, each University has been allocated a specific area of focus. The UCONN SHAP3D site will focus on 3D printing applications for aerospace, shipbuilding and biomedical applications. At UMass Lowell, researchers will work to develop new printing and processing methods as well as developing new polymer feedstocks for future 3D printing. And, thirdly, Georgia Tech will focus on developing new functional materials and hybrid printing technologies as well as studying design methodology.

“We’re trying to set up an ecosystem where we can all work together to solve fundamental research questions that are both intellectually stimulating and technologically relevant to the additive manufacturing field,” said Anson Ma, an associate professor in the Department of Chemical and Biomedical Engineering and Polymer Program, UCONN.

SHAP3D director Professor Mead added, “This new center is really exciting and we’re so glad NSF supports our vision and is willing to fund it,”

“The whole is larger than the sum of its parts, so we are looking forward to expanding this center to include more universities, industry partners and government agencies.”

For all of the latest additive manufacturing news subscribe to the 3D Printing Industry newsletter. Also, find us on Facebook and like us on Twitter.

Looking for jobs in engineering? Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

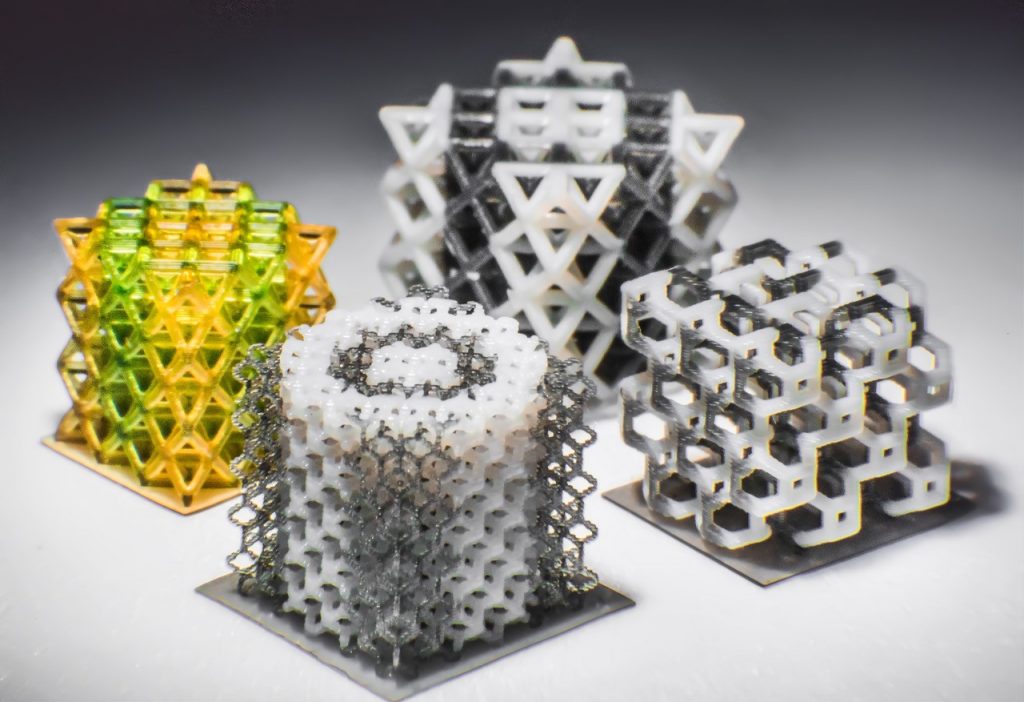

Featured image shows multi-material 3D Printed Objects. Photo via Kavin Kowsari/UCONN.