In the latest stage of GE’s Arcam EBM acquisition, wholly owned subsidiary GE Sweden Holdings AB has started to buyout the remaining stakeholders of the Swedish electron beam melting (EBM) metal additive manufacturing company.

Global investment firms Elliott Management and Polygon Investment both yielded their shares, and as of 29 December 2017 GE holds approximately 95% of the stake Arcam up from 77%. Additionally, GE has requested that Arcam applies for delisting from the Stockholm Stock Exchange as it plans to buy the remaining 5% of shares, but formal decisions have yet to be made.

GE’s additive backbone

Though GE’s overall share price has significantly decreased of late, its additive manufacturing business has continued to thrive. The company has teased details of its forthcoming H1 metal binder jetting 3D printer, and broken records in turbine efficiency with thanks to 3D printing.

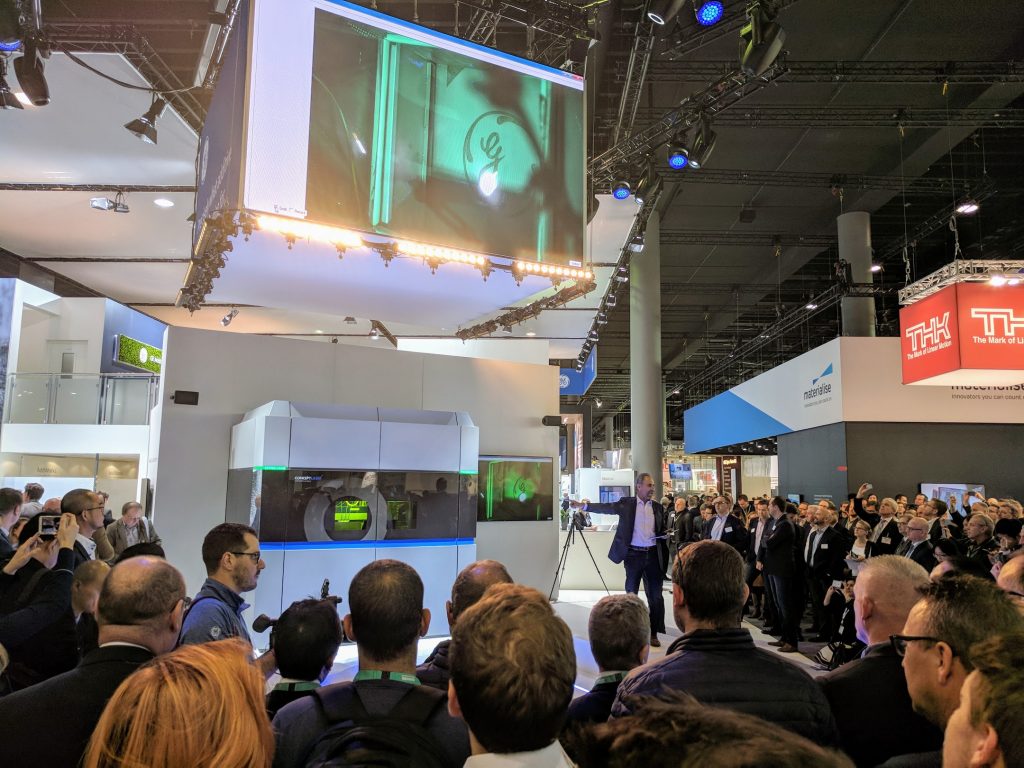

At formnext in the latter half of 2017, GE also beta launched the latest fruits of its labors with Concept Laser, the powder bed laser based “M2 Cusing” provider acquired at the same time as Arcam.

GE’s offer to Elliott and Polygon was made as part of initial acquisition discussions in October 2016. At the time both parties declined the offer, and the holdings company has since upped its bid by 5%, acquiring the combined 18% for 345 SEK ($42.15 USD) per share.

Swedish expansion

Just one week before GE’s renewed stake, Arcam EBM announced plans to expand its additive manufacturing capabilities in a new Swedish facility. Three times the size of the company’s existing site, the facility has been devised to “increase machine production capacity and allow for a more collaborative set-up within the company; uniting logistics, research and development, services and operations.”

First activity at the site can be expected in 2019, and will be bolstered by enhanced powder production at AP&C in Canada.

To stay up to date with all the latest additive business news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows a bowl of metal 3D printed GE-spheres. Photo by Beau Jackson