Expanding support for new and existing customers in Europe, GE Additive has launched its Customer Experience Center in Munich. The new 2,700 square meter facility is the first international center of this kind from GE. The chosen location also makes it neighbor to a number of other key players in the 3D printing industry, contributing to a growing hive of additive manufacturing activity around the Bavarian capital.

Sharing the knowledge

GE Additive’s Munich Customer Experience Center has been launched with an initial investment of $15 million. It employs around 50 staff, and is co-located at GE’s European Technology Center – part of the company’s Global Research effort.

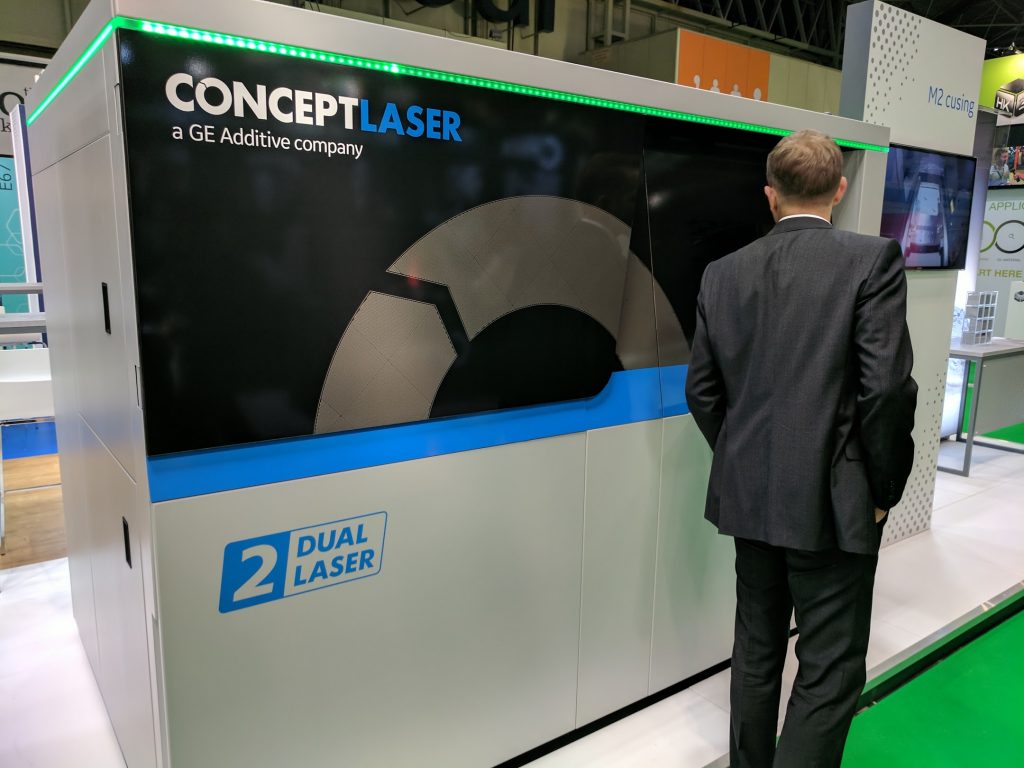

Installed with 10 metal 3D printers from both Concept Laser and Arcam EBM, visitors to the center in Munich can experience every part of the additive workflow, from design through to operations. Experience options include training programs at GE’s Additive Academy, and support for production of spare parts and powder handling.

The center was officially opened by Mohammad Ehteshami, Vice President & General Manager GE Additive, in the presence of internal employees, and representatives of companies including BMW, and Oerlikon, that also have facilities around Munich.

At the heart of the additive revolution

Robert Griggs is Customer Success Leader at GE Additive. In his statement about the new Customer Experience Center, Griggs highlights Munich’s position in the global additive market as a key factor in the inauguration. Griggs says, “The opening of our Customer Experience Center here in Munich marks a great milestone for us. Germany is the global innovation hub for additive manufacturing,”

“Right here, at the heart of the additive revolution, the center will operate as the interface between customers and our teams, combining the strengths of Germany’s Concept Laser and Sweden’s Arcam […]”

Incidentally Ehteshami and other GE affiliates Frank Herzog, the founder of Concept Laser, and Alf Henryk Wulf, CEO of GE Power, were guest speakers at the 1st Munich Technology Conference earlier in 2017. Held at the Technical University of Munich (TUM) the conference discussed additive manufacturing industrilaization, applications and business models, serving to highlight the global and local success of the technology.

Tobias Baur from TRUMPF, Airbus’ Jonathan Meyer and Dr. Hans Langer, founder of EOS, were among the conference’s other speakers, all sharing a proximity with GE Additive in “the heart of the additive revolution.”

Additive potential

Closing the statement on Munich’s Customer Experience Center Griggs comments, “We look forward to working closely with European companies and institutes, allowing them to fully realize the transformative potential that additive design and manufacturing can bring,”

“We’re excited about the types of products they will design and the improvements they can make to their operations using additive.”

In other recent news, GE Additive has released further details about the ongoing expansion of Concept Laser’s headquarters in Lichtenfels, Germany, which is due to for completion in 2019. The company’s power division has also broken records with the efficiency of its 3D printing facilitated HA turbine.

Stay up to date on all the latest additive trends – subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Make your nominations in the second annual 3D Printing Industry Awards here.

Featured image shows the new Customer Experience Center in Munich. Photo via GE Additive