Brooklyn-based 3D printer manufacturer gCreate has announced the launch of its latest system: the gMax 2 PRO.

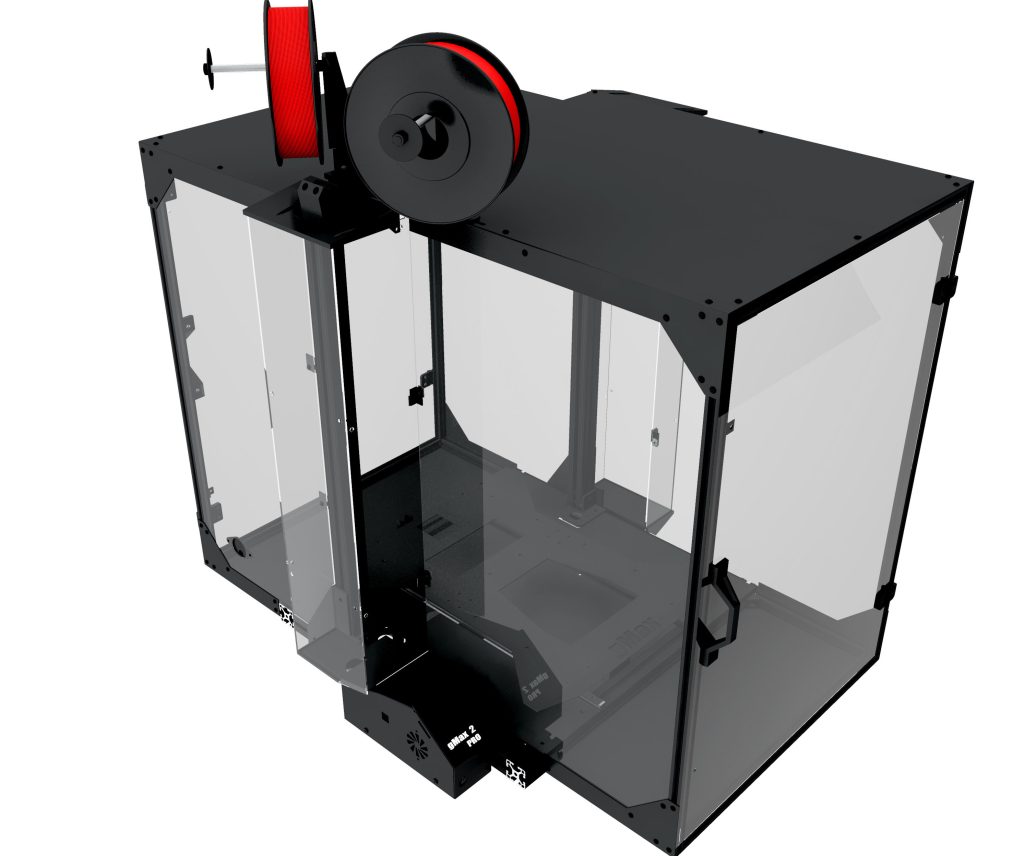

Featuring an 18 x 18 x 24 inch build volume with optional enclosure, compatibility with engineering-grade materials like PEKK, sintered-to-full metals and carbon fiber composites, and a starting price of $4,895, the desktop machine is being marketed by gCreate as an “affordable, scalable solution to America’s supply chain woes.”

“The US government and businesses are actively strengthening the domestic supply chain to have greater operational control, which makes perfect sense,” says gCreate Co-founder Gordon LaPlante. “The gMax 2 PRO allows companies to bring prototyping and manufacturing reliably in-house, which saves time, money, and protects valuable Intellectual Property (IP).”

gCreate’s desktop system portfolio

Since being founded in 2013 by LaPlante alongside Anna Lee as a two-person start-up, gCreate has flourished into a developer of large-format FFF 3D printers with industrial-grade capabilities. Working from its base inside the Brooklyn Navy Yard, the firm has managed to attract business from the likes of the US Navy, CDC, Harvard Innovation Labs and HP, thanks largely to its growing machine portfolio.

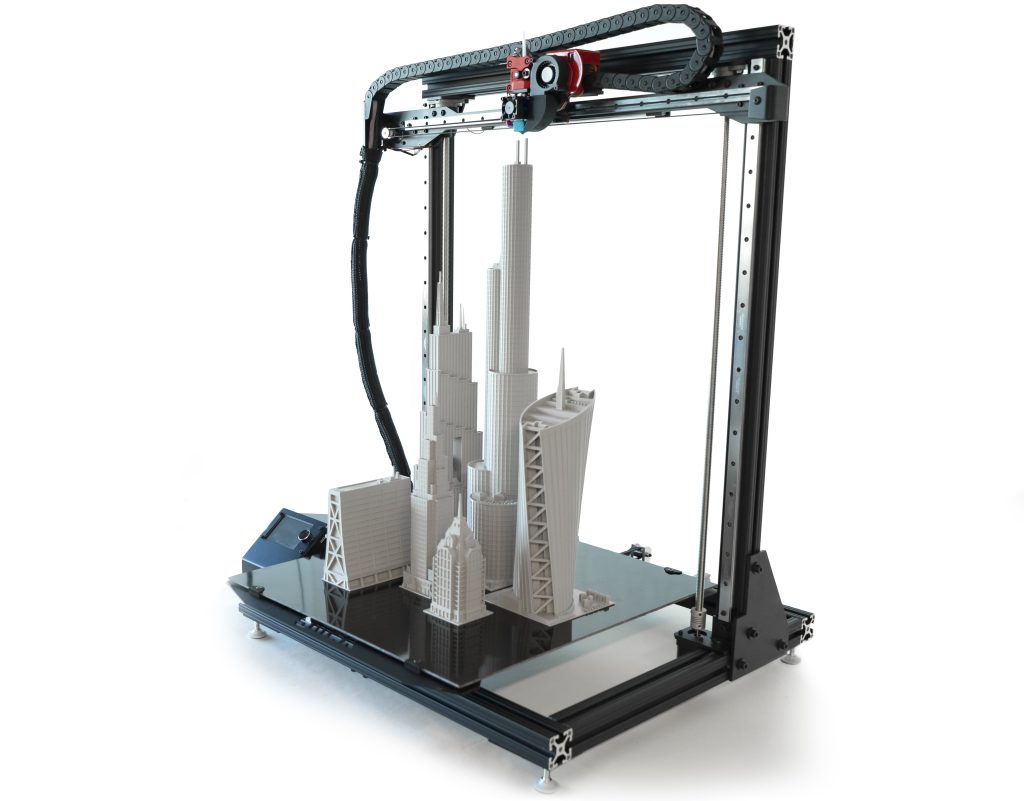

The first of gCreate’s 3D printers was the gMax 1.0, a desktop assembly kit, initially devised to meet LaPlante’s architectural modelling needs while he was still studying at the Pratt Institute. Designed to be put together by customers at home, the system offered makers and designers everywhere an easy-to-assemble system with a larger-than-usual build volume, and it raised nearly $130,000 in an early Kickstarter.

However, rather than following up on the success of the gMax 1.0 with an entirely new 3D printer, the company has since chosen to iterate on its original design instead. This, in turn, has led LaPlante and Lee down a path of continually upgrading their machine, first culminating in the gMax1.5, then the gMax 1.5 XT+, the gMax 2.0 and now the gMax 2 PRO.

Embracing enclosed 3D printing

With its latest addition to the gMax series, gCreate is offering buyers the chance to embrace the benefits of enclosed additive manufacturing. Available as an optional extra with the gMax 2 PRO, the firm’s proprietary enclosure is designed specifically for attaching directly onto the system’s frame, in a way that’s said to enhance its overall visibility, safety and strength, without requiring the use of a table.

However, the 3D printer’s core performance isn’t reliant on the enclosure, as even without it, the machine is capable of processing materials at temperatures of up to 400°C, with a print speed of over 200mm per second. Thanks to its broad thermal range, the gMax 2 PRO can print everything from standard prototyping filaments to engineering-grade nylons, into both high-quality mock-ups and end-use parts.

To ensure that even inexperienced users get the most out of their new systems, gCreate also ships them flat-packed, fully-assembled, calibrated and extensively pre-tested, meaning that they’re ready for deployment straight out of the box.

Elsewhere, on the application front, the firm boasts that its machine has already been used to address use cases ranging from drone cover prototypes and supercar parts, to standard jigs and fixtures. Given the supply chain instability that’s been laid bare by COVID-19 over the last two years, Lee adds that she believes the system could now be used more widely for in-sourcing by US-based manufacturers.

“To be able to offer a solution to help combat the current disruptions within the global supply chain and protect the US from future calamities is something that we are very excited by and passionate about,” adds Lee. “We are proud to be a NYC-based company that is manufacturing domestically, creating local jobs and supporting the efforts to bring manufacturing back to America.”

Technical specifications and pricing

Below are the technical specifications for the enclosed version of the gCreate gMax 2 PRO 3D printer. The system is available to buy now for $4,895 as standard, $6,295 with an enclosure, or $7,475 for the machine’s ‘PRO Bundle,’ which comes complete with rolling cart, reinforced build plate and an ongoing support plan.

| Technology | Fused Filament Fabrication (FFF) |

| Layer Resolution | 0.01mm Micron to 0.9mm Micron |

| Print Speed | 200+ mm/sec |

| Heated Bed | 18.5” x 18“ Ultra Durable Glass Fiber Reinforced |

| Bed Levelling | Genuine BLTouch Smart Bed Leveling Sensor |

| Electronics | Arm Cortex-M4 STM32 Processor |

| Dimensions | 18″ x 18″ x 24″ inches |

| Weight | Approximately 80lbs |

| Power Supply | 120v/240v Micro ATX |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the fully-enclosed version of gCreate’s gMax PRO 2 3D printer. Image via gCreate.