Forward AM, a brand of global chemical specialist BASF, has acquired the XSTRAND business line from materials developer Owens Corning. The acquisition, effective August 06, involves the transfer of the brand and key intellectual property, but will not involve any changes in personnel.

The move has allowed Forward AM to expand its 3D printing materials portfolio with advanced glass fiber reinforced filaments. The materials are typically characterized by their high strength and are designed to meet the needs of high-stress, demanding applications.

François Minec, Managing Director of BASF 3D Printing Solutions, explains: “Through the acquisition of the Owens Corning XSTRAND business, we are able to serve our customers with new and innovative filaments for 3D printing. By adding these high-performing materials, Forward AM now offers one of the broadest product ranges in the entire Additive Manufacturing industry, with expert solutions tailored to all industrial customer needs.”

The XSTRAND product line

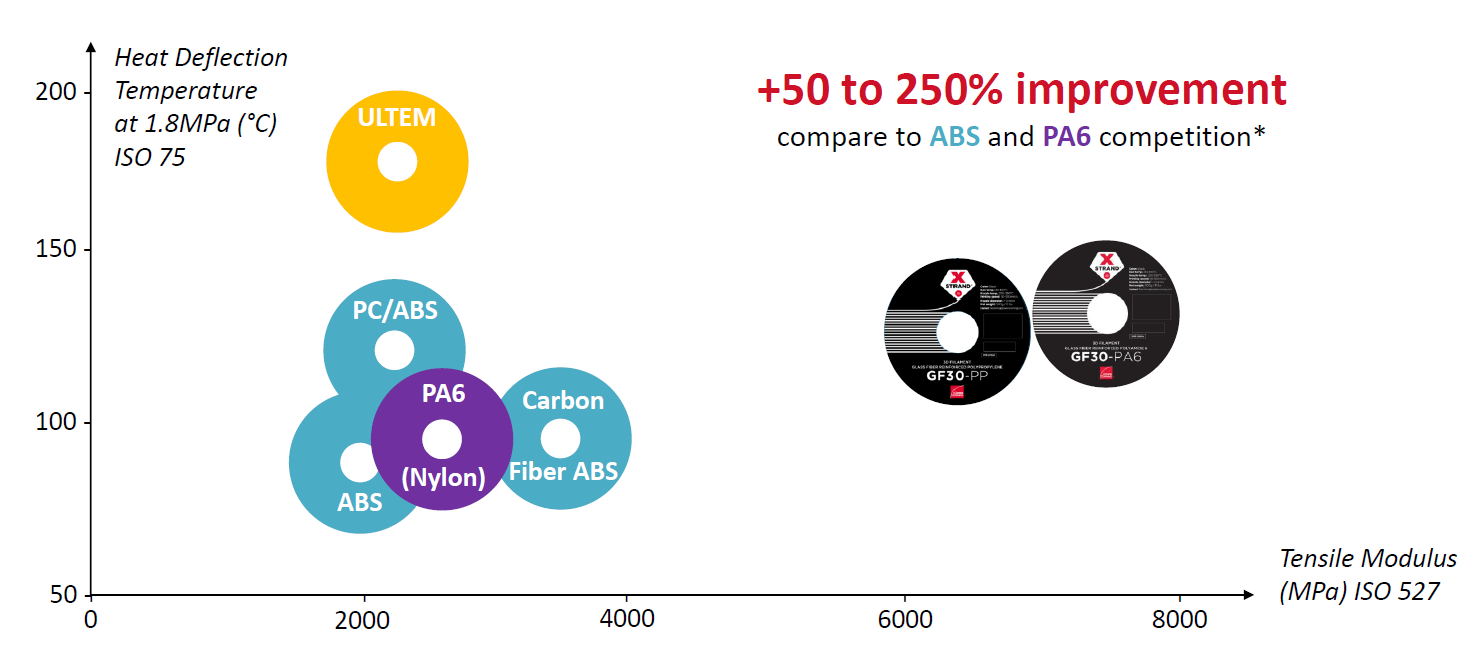

The product line acquired by Forward AM comprises three different glass fiber reinforced filaments developed by Owens Corning – polyamide 6, polypropylene, and polycarbonate. Each of the materials has a 30% glass fiber infill, striking a balance between easy printability and high rigidity.

According to Forward AM, the XSTRAND line’s mechanical properties far outperform almost any market standard polymer filaments. The integrated glass fibers also give the filaments excellent heat deflection properties and high durability, making them particularly suited for automotive and certain household appliances.

Dr. Christopher Skinner, Vice President of Strategic Marketing at Owens Corning, adds: “BASF’s capability will enable the further acceleration of XSTRAND products and support future growth of the composites industry. Owens Corning will continue its collaboration with BASF as we transition XSTRAND to them.”

Reinforced materials

In a bid to make materials stronger and tougher, materials scientists often employ fiber reinforcements. This has transferred over to 3D printing as well, as composite printing specialist AREVO recently unveiled its carbon-fiber-reinforced e-bike frame. The one-piece structure was produced using AREVO’s proprietary continuous fiber 3D printing technology, and is “extremely impact-resistant”.

Elsewhere, the U.S. Army is taking this a step further by reinforcing polymer filaments with other polymers. A research project published in April saw the development of a polycarbonate-reinforced ABS filament for use with low-cost FFF 3D printers. The high strength filament is expected to aid in the field of battle, producing mission-critical parts in a timely manner at a fraction of the cost of traditional parts.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the XSTRAND glass fiber reinforced product line. Photo via Owens Corning.