Boston-based Digital Composite Manufacturing (DCM) company Fortify has partnered with Dutch multinational chemical company Royal DSM to develop composite materials for the 3D printing of structural parts.

The collaboration will utilize Fortifiy’s DCM platform and fiber processing expertise in conjunction with DSM’s 3D printing resin knowledge. Together the companies will develop composite materials distributed through Fortify hardware for various markets including automotive, aerospace and electronics.

The update comes after Fortify revealed that Royal DSM had backed its Fortify Fiber Platform, launched following $2.5 million seed funding for the company. The platform invites industrial partners to help develop high strength resins in partnership with Fortify material scientists and engineers.

“At DSM Additive Manufacturing, we believe that collaborating with industry partners is key to advance the industry,” commented Hugo da Silva, VP of Additive Manufacturing at DSM.

“Partnering with Fortify allows us to develop high-performance composite materials for DLP technology, making the technology viable for functional parts in demanding applications.”

Expanding the Digital Composite Manufacturing platform

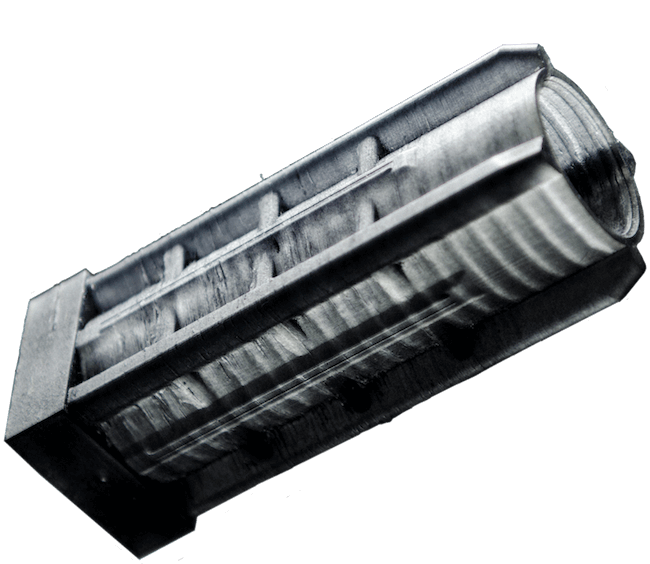

Fortify’s DCM platform aims to make advanced composite materials accessible for engineers and designers. The platform is propelled by Fortify’s patented Fluxprint technology, a process that combines magnets with DLP 3D printing for the alignment of fiber reinforcements, optimizing composite materials. The DCM service contains Fortify’s carbon fiber, fiberglass and ceramic composite materials, and is also supplemented with INFORM generative design software.

With DSM now a part of Fortify’s Fiber Platform, the two companies will leverage DCM to build upon the mechanical properties of DSM’s resin. Fortify will also distribute DSM’s 3D printing materials through its DCM platform, expanding the range of high strength resins that are already available through the service.

“DSM is an ideal partner for us,” said Josh Martin, CEO of Fortify. “Our collaboration allows us to leverage DSM’s mature supply chain and years of experience developing advanced materials to expand our resin palette. We’re excited to partner with an industry leader and work with them to develop cutting-edge resins.”

A series of distribution deals and collaborations for Royal DSM

Founded in 1902, Royal DSM is a global chemical company specializing in nutrition, health and materials. The company’s collaboration with Fortify is the latest in a line of partnerships that will see DSM’s materials available through different services. DSM has a broad range of materials suited to FFF, SLS, SLA, ink jet and binder jet 3D printing processes.

DSM recently entered into an agreement with Dutch supplier FormFutura to distribute DSM’s 3D printer filament, allowing the company to extend its global reach. Jill Cohen, Global Director Marketing & Sales for DSM Additive Manufacturing, stated that “At DSM, we believe that partnerships across the additive manufacturing ecosystem are critical to unlock the full potential of this new technology.”

DSM is also a part of the Ultimaker Material Alliance Program, a collaborative platform designed to enable a range of engineering materials that are compatible with Ultimaker 3D printers. DSM offers print profiles available on the Ultimaker Cura software marketplace, giving users access to its materials for FFF 3D printing.

It is now your final chance to make nominations for the 2019 3D Printing Industry Awards.

Want the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Begin your career in additive manufacturing by visiting 3D Printing Jobs today.

Featured image shows a 3D printed sample from Fortify. Image via Fortify.