Gillette, the shaving supply and razor brand of Procter and Gamble, has partnered with Boston 3D printer developer and manufacturer Formlabs.

Through a pilot project in the U.S., dubbed Razor Maker™: powered by Gillette®, the two businesses are providing consumers with custom 3D printed razor handles.

Pankaj Bhalla, Director of Gillette & Venus North America, comments, “The Razor Maker™ pilot furthers our commitment to place power in the hands of consumers and literally have them custom-make their razors exactly the way they want them – tailored to their grooming preference, budget, look, color and style,”

“This is one of the many ways we are fulfilling our commitment to being The Best A Man Can Get.”

Gillette’s “a razor by you”

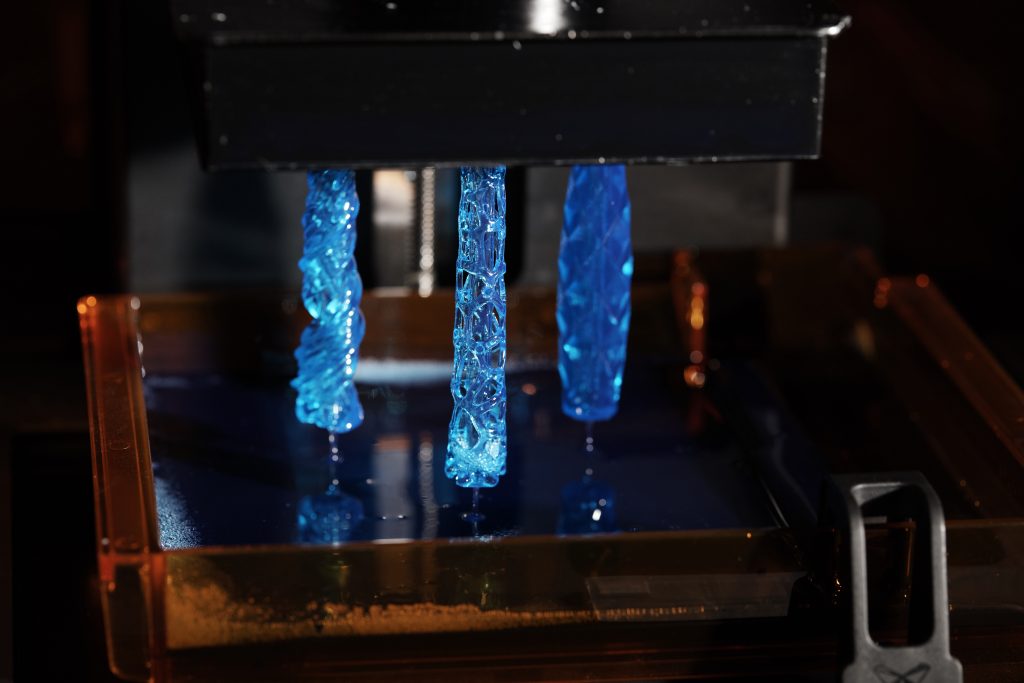

Razor Maker handles are available in 48 3D printed designs that would be impossible to make using traditional manufacturing techniques. Each one is sorted into one of three different levels of 3D printing, i.e. partially printed, fully printed, with chrome effect. These level relates to the cost of the overall product:

– Partially 3D printed with a black rubberized grip: $19

– Fully 3D printed: $25

– Finished with chrome: $45

The designs, taking shape as waves, honeycombs and other organic textures, are completed by a choice of seven color options and text or initials set by the customer. When finished, the handles are compatible with either three-blade MACH3 or five-blade Fusion5 ProGlide cartridges.

The next 3D printed mascara brush?

A hot topic for brands seeking a custom finish to their mass produced products, 3D printing is seeing a variety of applications in the consumer goods industry.

EOS and Under Armour, adidas and Carbon and the Reebok Liquid Factory are some of the notable 3D printed sneakers projects that have some to the fore in recent years. On the introduction of the Fuse 1, Formlabs also launched its own 3D printed footwear partnership with New Balance.

In terms of 3D printed products available to purchase in-store, one brand that stands out is Chanel. In March 2018 the famed fashion house introduced 3D printed tips to a brand of mascara brushes.

“Mass customization with 3D printing is finally becoming a reality for consumers to experience end-use printed products,” comments Dávid Lakatos, Chief Product Officer of Formlabs. “Historically, 3D printing has been involved in the development or manufacturing processes for most products people interact with every day, but consumers have had little interaction with 3D printing itself,”

“We’re thrilled to be partnering with Gillette. These new custom razor handles are the next step towards changing that dynamic and getting 3D-printed products directly into the hands of consumers.”

For all the latest industry partnerships subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Create a free profile on 3D Printing Jobs, or advertise to find expertise in your area.

Featured image shows the Razor Maker™: powered by Gillette® line of handles. Photo via Gillette/Business Wire