Formlabs, a Massachusetts-based 3D printer manufacturer has introduced its latest material formulation, High Temp Resin, for the Form 2 stereolithography (SLA) 3D printer.

Designed to print detailed, precise prototypes with high-temperature resistance, High Temp Resin offers an improved elongation to decrease brittleness as well as a heat deflection temperature (HDT) of 238°C (at 0.45 MPa), the highest among Formlabs resins.

High Temp Resin

Formlabs first soft-launched High Temp Resin last year for engineers and product designers to better understand its applications, strengths, and opportunities to improve. The company saw a variety of professionals use its latest material formulation within the functional testing of prototype parts prone to come into contact with heat.

Materials commonly used within rapid prototyping can deform at higher temperatures. This material enables the production of fully dense, watertight parts with low absorption that can withstand direct contact with hot liquid or steam.

Furthermore, High Temp Resin supports print resolutions of 100, 50, and 25 microns. According to Formlabs, in some cases, engineers have bought their first Form 2 specifically to access this resin.

Optimized production with High Temp Resin

The Google Advanced Technology and Projects (ATAP) lab has used High Temp Resin to overcome several pre-production additive manufacturing challenges. The ATAP team needed to quickly produce hundreds of prototype PCBs to validate an overmolded wearable device.

Using High Temp Resin, which demonstrates high thermal stability, they reduced turnaround time for the crucial component by 85% while saving over $100,000.

“You might shoot hundreds and hundreds, thousands of shots, to dial this in,” said David Beardsley, Model Shop Manager at Google ATAP. “The problem is when you’re doing that with live electronics that have real boards that have been stuffed with real electronics and then sent off to the overmolder and then brought back, you’ve got this whole supply chain.”

“Had we not had the Form 2 [and High Temp Resin], we would not have been able to pull this off. When we did move to a full product cycle, we were sure that was going to work.”

Moreover, New York-based OXO, a producer of consumer goods, utilized High Temp Resin to prototype functional parts that needed to come into contact with boiling water during the design process for its Barista Brain 9 Cup Coffee Maker.

In addition, the Advanced Manufacturing Research Center (AMRC) at the University of Sheffield integrated High Temp Resin to rapidly test washers and brackets for different sensor configurations that can withstand the high temperatures of welding.

The new formulation, High Temp Resin, is shipping now at a price of £204.

Stay up to date with Formlabs and the latest 3D printing news by subscribing to our free newsletter. Also, follow us on Twitter and like us on Facebook.

To start your career in additive manufacturing or post new opportunities, join 3D Printing Jobs.

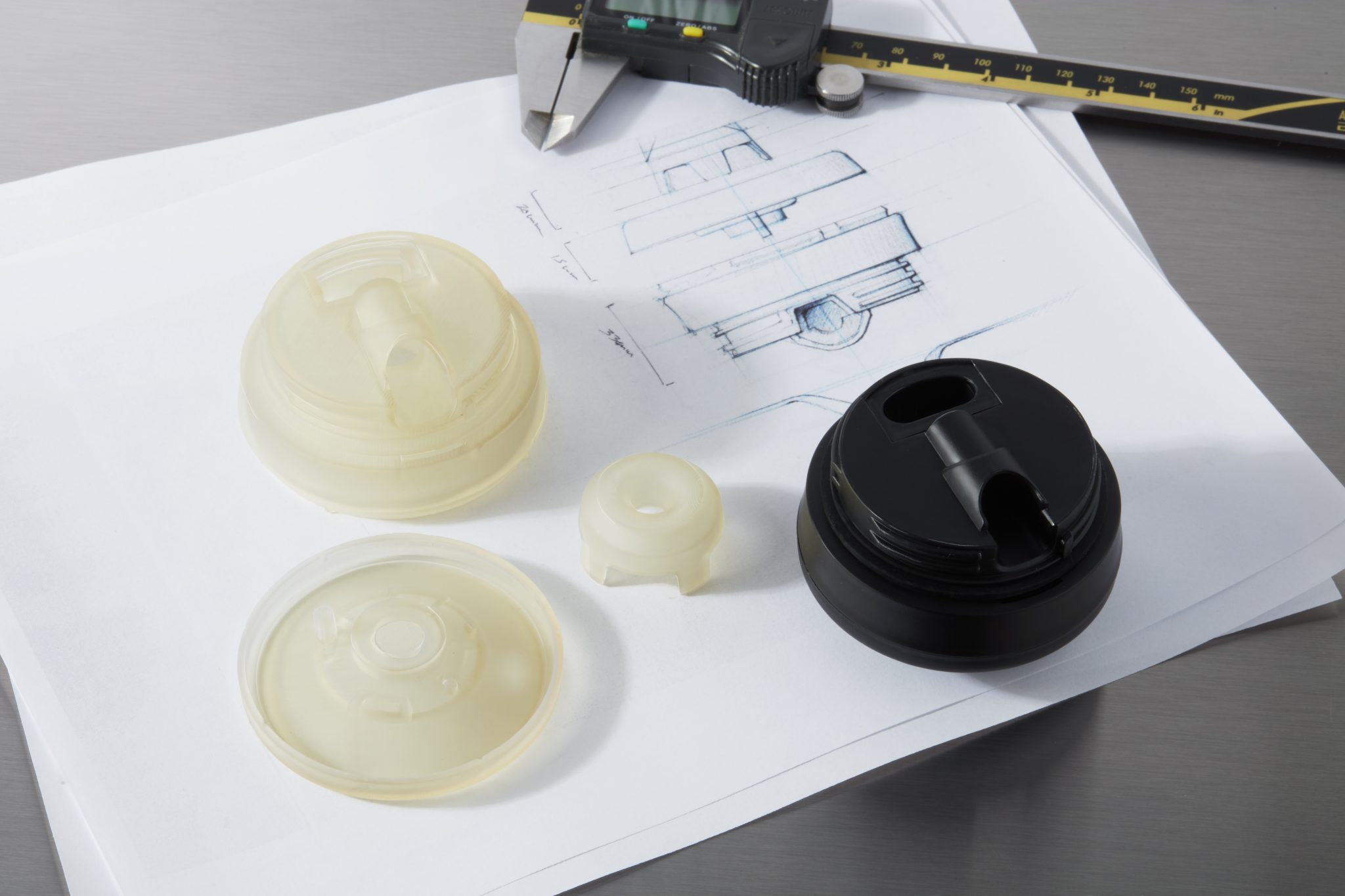

Featured image shows 3D printed parts using Formlabs High Temp Resin. Photo via Formlabs.