Founded in 2009, Growthobjects is a digital manufacturing design studio headed by Xavier Tutó and Katia Glossmann (designers), and Jordi Bayer (engineer). They specialize in creating amazing 3D designs that they 3D print using the latest technologies from EOS, 3D Systems, Digital Metal, Sciaky and other companies, using both plastics and metal to test the boundaries of what can be 3D printed. What they learn they share with universities and academic institutions across Europe, teaching students how to master 3D processes, and offering support for scientific research projects such as fossil replication.

However that is just part of the picture and what makes the Barcelona and Girona based studio particularly interesting is that they have found a commercial niche that combines their artistic talent with a successful business. For the strangest coincidence (I was staying in Barcelona for one day, less than 500 meters from the Growthobject studio, when I received Editorial direction to cover the company for 3DPI) I had the opportunity to visit Growthobjects and see for myself what they are capable of accomplishing through direct digital manufacturing.

They have mastered all techniques, including, but not limited to, LS, SL, DLP and FDM, and for each project they undertake they are able to choose the technology that can best suit requirements and reduce costs. They can then offer these services to private companies who need to make up individualized trophies for competitions, prizes for awards, gadgets and PR items for events. The list goes on and on but the commercial aspects involved certainly do not stifle their creativity.

For example they developed individualized awards to present to the speakers at the University of Basel 2013 RIGI Workshop. Taking the form of natural complex shapes, such as molecules and DNA, the jewels, printed in wax and casted in silver, also inspired a line of “molecular” jewellery, for sale through Growthobject’s eCommerce site.

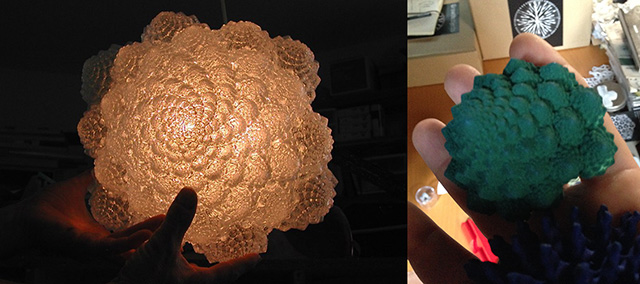

I was particularly impressed by a miniature “fractal cauliflower”. Nature’s patterns in something as common as any broccoli-related plant are amazing when viewed up close: to be able to replicate that, not just virtually but physically, is an impressive feat. Even more so when it can be used to create a lamp, through SL additive manufacturing.

Their most successful projects also include a relatively simple but captivating kid’s game based on matching key shapes (printed through a basic Rep-rap style FDM machine), as well as flowers with Braille text poems imprinted onto each petal for a University of Girona project aimed at people with visual disabilities.

Growthobjects also mastered direct metal printing. Along with an award 3D printed in titanium, they showed me a beautifully patterned object printed in stainless steel, only a few microns thick. It had been commissioned by Swedish metal-powder giant Hoganas, to represent the logo of their metal additive manufacturing division, Digital Metal, and show off their most advanced capabilities. Insert Image: metal printing microns.jpg The projects go on and on. “The main difficulty we are faced with – Xavier Tutó told me – is making companies fully a understand the advantages that digital additive manufacturing can offer them. It will take some time but there are enormous margins for growth”.

To keep track of all the activity and to make their services and 3D printed creative works easily available, Growthobjects launched the new website last October. It is not meant to be a point of arrival but a launch pad on the road to growth in the digital manufacturing and 3D printing arena, a way to fulfill their “growth objective”. Creating products that companies are happy to pay for is likely to be a good place to start.