Australian satellite developer Fleet Space has revealed plans to launch a new generation of 3D printed small satellites in the next 12 months, called Alpha.

Claimed to be the world’s first entirely 3D printed satellite, the Alpha will integrate the company’s advanced beamforming technology and patented antennas to unlock greater connectivity more quickly and in more locations.

“It is Fleet Space’s vision that everyone, everywhere, has access to unlimited connectivity, no matter where they are on the globe, in cities, remote regions, on land or navigating the oceans,” said Flavia Tata Nardini, CEO and Founder of Fleet Space. “Our recent Series B investment empowered us to realize this vision by embarking on a bold new strategy.”

Aiming for unlimited connectivity

Fleet Space made history by launching Australia’s first four commercial nanosatellites into Low Earth Orbit (LEO) back in 2018, namely its Proxima 1 and 2 and its Centauri 1 and 2 satellites. The firm has since continued work on its Centauri program and launched its fifth and sixth satellites earlier this year.

Last month, the company secured $26.4 million in Series B funding to bolster its mission to provide global satellite Internet of Things (IoT) connectivity. Upon the funding announcement, Fleet Space was valued at $126 million and backed by the likes of Artesian Venture Partners, Blackbird Ventures, Grok Ventures, and Horizons Ventures, among others.

Fleet Space has a history of firsts within advanced manufacturing, including a world-first in metal 3D printing patch antennas for small satellites which delivered 10 times more throughput per kilo of spacecraft. Now, the company is funneling its expertise and fresh capital into creating a new generation of small satellites with improved connectivity capabilities.

“This new chapter in our story is led by the development of a new constellation of satellites named Alpha, which will work in harmony with our existing Centauri constellation,” said Nardini. “Alpha represents a major step forward and the first time a satellite has been created entirely through 3D printing.

“By bringing together the creation, deployment, and service of space technology this is a clear statement of our intent to become a global leader in space technology, and to support Australia’s ambition to lead this critical field.”

The Alpha constellation

Fleet Space’s new alpha constellation will sit alongside its existing Centauri satellites, which are among the world’s most advanced space communications systems. The company plans to leverage the experience and learnings from its growing constellation of small satellites to develop the Alpha and subsequently expand its coverage reach. The firm hopes to provide down to sub-seconds latency to deliver a cost-effective means of providing “unprecedented” connectivity more quickly and in more locations.

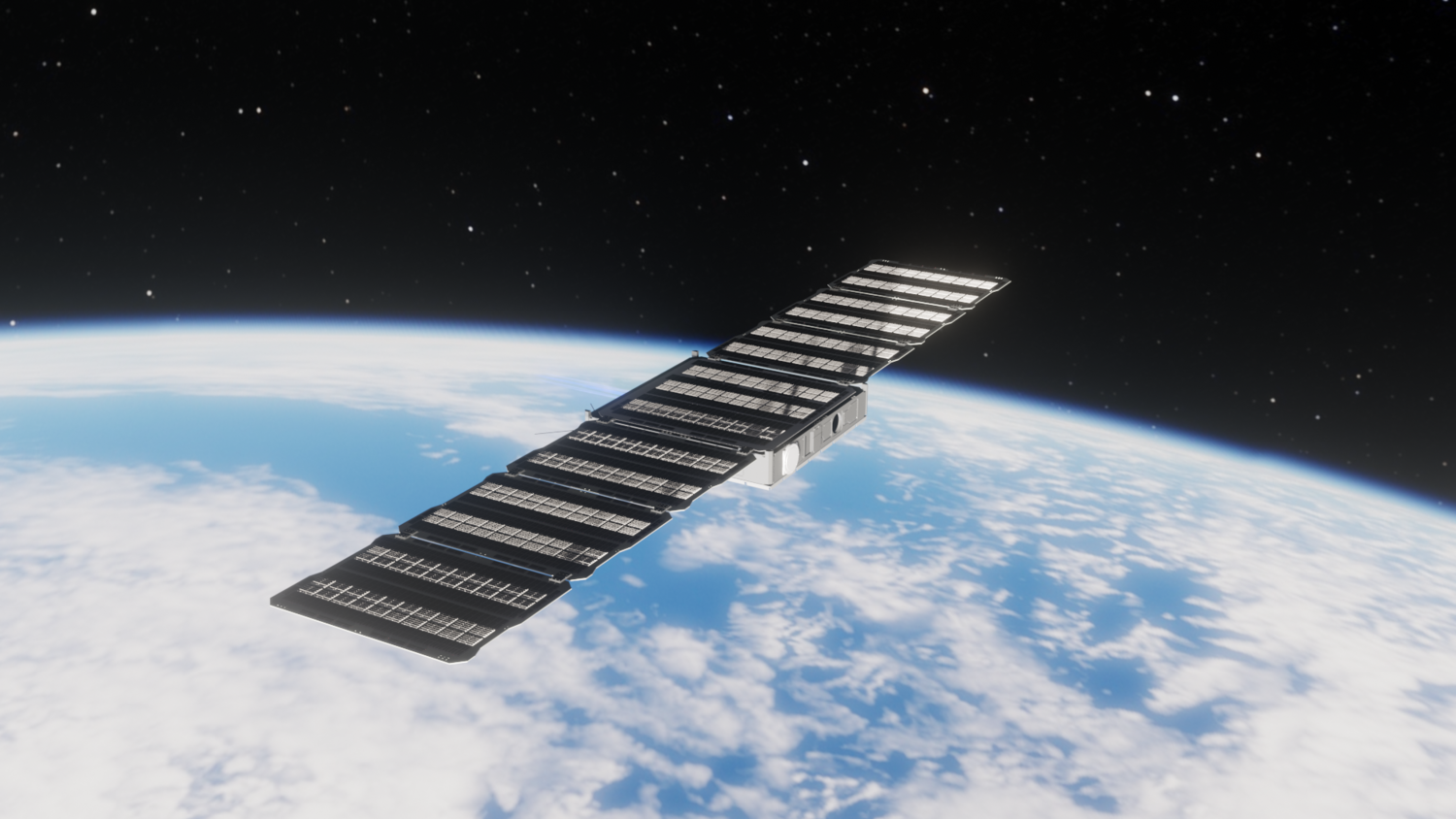

According to Fleet Space, the Alpha will represent the world’s first entirely 3D printed satellite. The satellite will be integrated with the company’s advanced digital beamforming technology that uses an array of multiple 3D printed all-metal antennas along with Digital Signal Processing capabilities.

The technology generates a high number of highly-directional low-interfering beams in point-to-point satellite communications to substantially increase the throughput of customer IoT data and subsequently service a higher number of customer terminals at once. This process delivers a high spectral efficiency which improves quality of service through enhanced frequency reuse, faster data rates, and more robust links.

The beamforming technology will be integrated into the LEO Alpha, which is not much larger than half a square meter, in another “world first” claimed by the company.

The Alpha will have up to 64 of the company’s metal 3D printed patch antennas compared to the four on Fleet Space’s latest satellite, the Centauri 4, representing a 16-fold increase in performance while being only four times heavier.

The Alpha satellite is estimated to be ready for launch in around 12 months, and represents a “fundamental shift” for Fleet Space as it expands the scope of its R&D arm. The Alpha will add to Fleet Space’s LEO small satellite network, which it is aiming to expand to a 140-strong constellation.

Bolstering Australia’s space sector

Fleet Space’s recent Series B funding marks a firm commitment to Australia’s burgeoning space industry, the company says, and will lead to the creation of 70 new jobs, many of which will be in STEM positions.

At the time of the announcement, David Pisoni MP, Minister of Innovation and Skills, said: “The growth of Fleet Space Technologies and the successful completion of this funding round is a glowing affirmation of the sustained development of the Australian and South Australian space industry sector.

“In backing Fleet, the Marshall Liberal Government is supporting the creation of highly-skilled jobs in South Australia and plotting a trajectory towards the Australian Space Agency’s stated aims to build a £12 billion industry by 2030.”

Aside from Fleet, there have been several recent additive manufacturing developments from other players in Australia’s space sector. Back in 2018, Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO) highlighted the importance of 3D printing for the development of the country’s space sector and the role it could play in achieving “Space 2.0”.

Since then, Melbourne-based metal 3D printer manufacturer Titomic has partnered with fellow Australian space firm Gilmour Space Technologies to 3D print high-performance rocket and space components for Gilmour’s launch vehicles. More recently, Titomic teamed up with on-demand production provider Romar Engineering to secure AUD $8.1 million in grants, which the firms will use to produce and commercialize satellite parts and fluid and motion control systems for future space missions respectively.

Meanwhile, the ProtoSpace of University of Technology Sydney (UTS) recently carried out a pilot project with Nano Dimension, a manufacturer of industrial 3D printers for additively manufactured electronics (AMEs) to harness the power of 5G for the space sector and advance 3D printed millimeter-wave and terahertz antennas and circuits.

Elsewhere, Australian metal 3D printer OEM AML3D announced plans to make its first entry into the space sector with a partnership with an unnamed aerospace firm, while Australian cold spray 3D printer manufacturer SPEE3D unveiled its own plans to “revolutionize” the space sector with low-cost metal 3D printed rocket engines.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows a render of the Alpha small satellite in LEO. Image via Fleet Space.