3D printer manufacturer Flashforge has added a new high-throughput, large-capacity 3D printer to its Guider 3 range.

Known simply as the ‘Guider 3,’ the system follows hot on the heels of the Guider 3 Plus, in that it uses Fused Filament Fabrication (FFF) to deliver professional-grade parts. That said, unlike the Guider 3 Plus, which enables the rapid prototyping of figurines, art and movie props, Flashforge’s latest machine is built to address the demanding cost-efficient production needs of small enterprises.

Featuring a CoreXY arrangement that supports a print speed of up to 250mm/s, and a material management system optimized for convenience, the Guider 3 is designed specifically to unlock streamlined production. In fact, Flashforge says, its system not only “greatly reduces printing time,” but enables adopters to “respond faster to customer demands,” and “seize market opportunities” whenever they arise.

Introducing a Guider 3D printing upgrade

Compared to the Flashforge Guider II 3D printer, the Guider 3 is 20% lighter and features a 21% faster print speed. While the frame of the machine itself is made from aluminum, its enclosure is constructed from lightweight, durable ABS and acrylic sheets. The minimalist design of this outer structure, therefore allows for the maximized use of the system’s internal space, thus facilitating its larger 300 x 250 x 340mm build volume.

To enable it to meet users’ small-batch production needs, the Guider 3 also incorporates an Equipment Management System that enables multi-machine joint control, as well as a real-time monitoring set up. Leveraging the unit’s in-built camera, adopters can observe the printing process through Flashforge’s proprietary FlashPrint 5 software , and track the quality of prints as they happen.

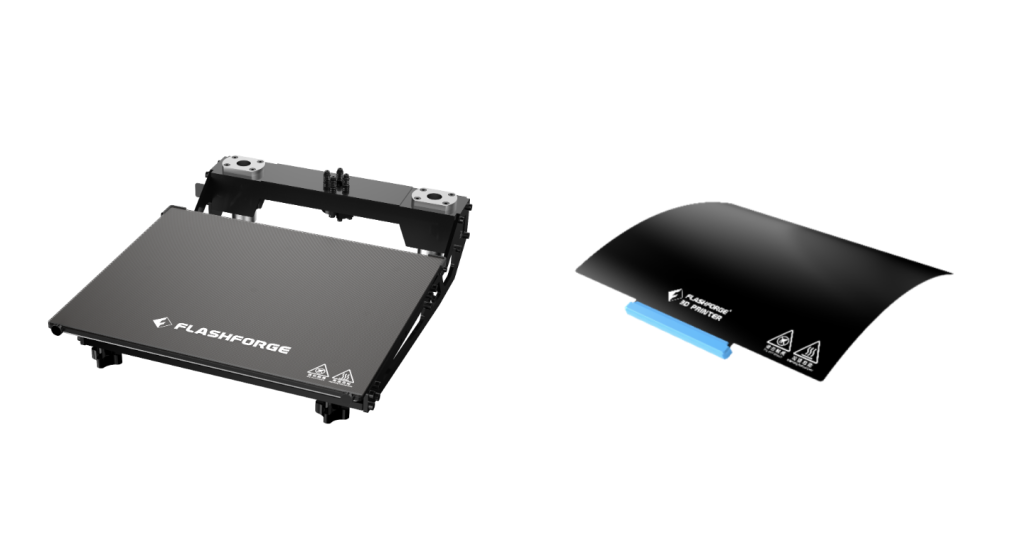

For those seeking a personalized 3D printing experience, Flashforge is shipping the Guider 3 with both a glass platform and flexible steel build plate, thus allowing users to configure the system to their desired use case. The former, for example, features a smooth, flat surface that makes it easy to remove models with a shovel or scraper, while the latter is easier to bend and therefore better for larger parts.

The Guider 3 also incorporates a more convenient bed leveling system than its predecessor, that combines auxiliary and automated leveling, in a way that allows users to print evenly without manual configuration. Similarly, the machine’s quick-assembly nozzle incorporates a double-gear extrusion structure which provides it with a 150% higher filament feeding force, something that’s great for preventing clogging.

Through the integration of all these upgrades, Flashforge hasn’t overlooked accessibility either, and the Guider 3’s nozzle is said to be easy to replace and maintain, while meeting various use requirements. Given the size, speed and open-material nature of its latest machine, Flashforge says it could be ideal for studios and small businesses with a limited budget and space seeking an ergonomic production unit.

Flashforge’s 3D printing portfolio

Flashforge has spent the last eleven years building out a portfolio capable of meeting the needs of users ranging from consumers, right through to those engaged in professional or industrial-grade 3D printing applications. While the firm’s initial Adventurer 3 and Adventurer 4 systems were made for the entry-level market, it has also gone on to launch the more capable dual-extrusion Creator Pro 2 and Creator Max 2.

The company’s efforts to build a turnkey 3D printing solution to meet different customer demands have culminated in its flagship system: the Creator 4.

Flashforge’s IIDEX (Interchangeable Independent Dual Extruder) machine features a 400 x 350 x 500mm build chamber with an advanced thermal-control system that allows users to print at a consistent temperature of 65℃. This facilitates good print quality, reducing shrinkage and warpage, and enables adopters to use over twenty different material types, including engineering materials as well as carbon or glass fiber composites.

On the professional-grade side of its business, Flashforge also continues to innovate with its Guider 3 series. Designed to address mid to large-format functional prototyping use cases, the Guider 3 Plus features a distinct tall-format build volume. Much like the new Guider 3, the system is therefore able to streamline product R&D, as well as being well-suited to manufacturing long, thin props or models.

Technical specifications and pricing

Below are the technical specifications for the Flashforge Guider 3 3D printer. While the firm is taking orders for the machine from August 31, 2022, interested customers can find out more about Flashforge Guider 3 via its dedicated website now.

| Build Volume | 300 x 250 x 340mm |

| Print Precision | ±0.15 mm |

| Layer Thickness | 0.05 ~ 0.4 mm |

| Print Speed | 10 ~ 250 mm/s |

| Max. Extruder Temp. | 320 °C |

| Display | 4.3-inch Smart Touch Screen |

| Connectivity | USB/Ethernet/Wi-Fi |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a Flashforge Guider 3 3D printer. Image via Flashforge.