While 3D prints at the touch of a button, à la Star Trek’s TNG replicator, may still be some way off, a number of enterprises exhibiting at the 2017 RAPID + TCT show are moving to save time at various stages of the 3D printing process.

Automating additive manufacturing production

Methods 3D have a booth opposite 3D Systems. During IMTS Methods 3D demonstrated how a 3D Systems Figure 4 configuration could operate using robotic arms. The robotic arms are now manipulating metal build plates and moving the metal additive parts between a Fanuc Robocut c600ib and a Fanuc Robodrill.

The robot arms seen at Formnext and IMTS are now gone from the 3D Systems booth. Instead, multiple Figure 4 quad engines are positioned around the booth. The more discrete units in fitting with the dental applications where this technology is likely to find earlier adopters. For dental applications 3D Printing Industry will be taking a closer look at the systems from EnvisionTEC and also DWS who are both at the show.

On the subject of time-saving and as we reported yesterday, 3D Systems has updated their 3D Sprint software to include Smart Support Technology. This means that SLA prints can be post-processed with rapid removal of supports. Speaking with Rachael Dalton-Taggart about the production of the video for the software update, she explained that the Tear Away SLA supports have been warmly welcomed by users at the company.

Post-processing is an area also addressed by Rize, who are at RAPID + TCT. The Woburn, MA based company sent me some samples last year. I can confirm that removing supports really is as fast as they say and recommend a visit to booth 1010 to see Rize demonstrate their Augmented Polymer Deposition 3D printing technology.

Other companies demonstrating degrees of automation include Mass Portal, who have expanded the print station from Formnext and now has an automated system to remove parts, called the Dynasty additive system.

Fast 3D printing from pellet materials

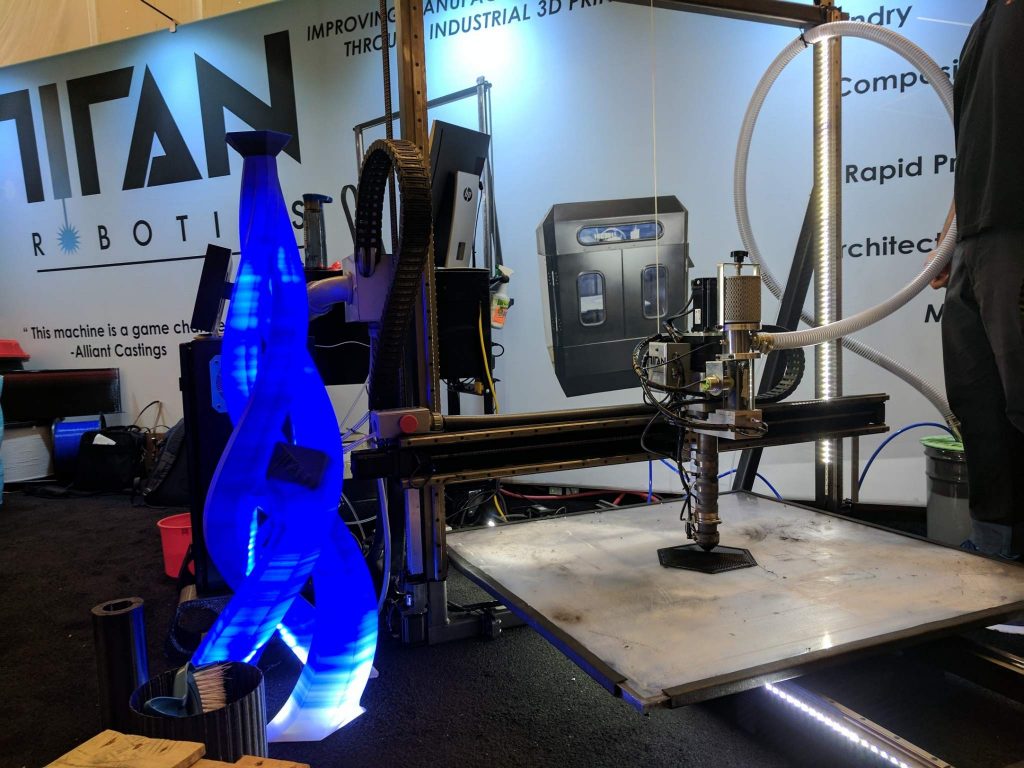

Titan Robotics from Colorado is at booth 837 and demonstrating their large-format FDM/FFF 3D printer that runs on pelletised materials. Deposition of over 2 kg/hr (5 lbs/hr) is offered and a range of prints in higher grade engineering materials including PC/PBT, HIPS and various carbon fiber materials are on display. Prints include a functional skateboard, although a half-pipe is yet to be printed.

Titan Robotics has also brought their Cronus 3D printer, the machine is on display over in the 3D playground. If you can’t get to RAPID + TCT then you can read our report on the 5-print-head Cronus 3D printer here.

For all the latest 3D printing industry news, subscribe to our free additive manufacturing newsletter and follow our active social media accounts.

Voting closes soon in our 3D Printing Industry Awards, the winners will be announced on the 20th May at a gala-dinner in London. You can see the shortlists and make your vote here.

If you’re at RAPID + TCT this week, then say hello to our editor-in-chief, Michael Petch.

Featured image shows 3D Systems 3D prints from a non-Star Trek sci-fi franchise. Photo by Michael Petch.