Czech 3D printer materials brand Fillamentum has launched another new FFF filament. Named Vinyl 303, this material is made from PVC, presenting excellent resistance to chemical corrosion, fire retardancy and high mechanical performance.

The material was developed by Fillamentum in collaboration with RESITECH GERMANY GMBH, a plastics specialist, and it is an industrial material – adding to the recently established Fillamentum Industrial sub brand. As such, Vinyl 303 is made for experienced 3D printer operators and must be processed appropriately in order to maintain its integrity, and mitigate any risk of harm. Fillamentum maintains, “3D printer operators must take into consideration the fact that hydrochloride acid is emitted during every processing of polyvinylchloride (PVC).”

“To prevent any harm we strongly recommend ventilating the room while printing. The best option for 3D printing with Vinyl 303 is to have a machine with a closed chamber. To protect your printer do not use stainless steel nozzles because they may corrode.”

3D printing one of the world’s most popular polymers

After polyethylene (PE) and polypropylene (PP), PVC is the third most widely produced synthetic polymer in the world. It has a high hardness and, as a thermoplastic, the polymer has an inherent insulation quality. Its resistance to chemical corrosion has earned the plastic widespread application for the production of everything from industrial piping, electric cables and flooring, to credit cards, vinyls and imitation leather.

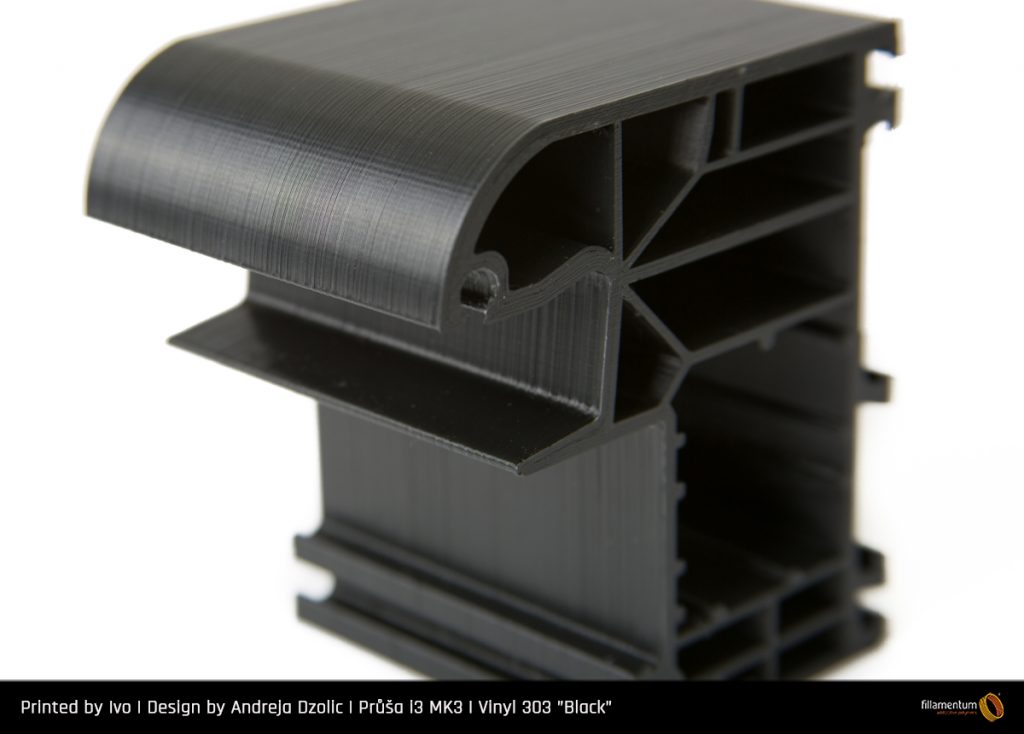

According to Fillamentum, Vinyl 303 is one of the first filaments to purpose PVC for 3D printing. In this composition, it has a tensile strength of 46.1 MPa, 13.1% elongation at break, and a hardness of 78 Shore D, making its finish almost equivalent to the hardness of a construction helmet (80 Shore D).

When melting Vinyl 303 it is important to stick within the recommended nozzle temperature for this material. A brass nozzle should be used as steel parts can corrode when used with PVC, and a 3D printer prepared with HEPA filters would be appropriate to use. “To prevent emissions, it is strongly recommended to follow given recommendations,” adds Fillamentum “For good printing results and for elimination of harmful fumes production, printers should respect the nozzle temperature, which in the case of Vinyl 303 is 215-230 °C.”

Further, bed temperature for the material should be set to 80°C, and recommended print speed should be in the range of 40–60 mm/s.

Industrial applications of 3D printed PVC

In addition to adequate ventilation, preparation should be made so that printed layers of Vinyl 303 are high enough to avoid nozzle clogging. If the nozzle clogs when 3D printing, this can increase the risk of harm from PVC fumes. Further, when a 3D print is finished, Vinyl 303 must be removed from the machine to avoid degradation of the nozzle.

RoHS compliant, the filament is safe for use in electronic equipment prototyping, as well as any application that requires long-term exposure to oils, salts and water. As with all PVC, Vinyl 303 3D printed products should never come into contact with food, or other consumable items.

Vinyl 303 is currently available in two colors – Vinyl 303 Natural and Vinyl 303 Black – and can be purchased as 750 g spools of 1.75 mm diameter.

For more of the latest 3D printing materials releases subscribe to our newsletter, follow us on Twitter and like us on Facebook. Visit 3D Printing Jobs for new opportunities in your area.

Featured image shows a Vinyl 303 Natural 3D printed pipe sample. Photo via Fillamentum