Netherlands-based 3D printer manufacturer FELIXprinters is working with the Institute for BioDigital Architecture and Genetics (iBAG-UIC) in Barcelona to investigate how biology, genetics, and the digital can be brought together to create “living” architecture.

Firmly believing that “biodigital is the future for architecture”, iBAG-UIC predicts that houses, cities, and landscapes will soon be made up of equal parts biological and digital, eventually culminating in a totally biodigital future for our cities. To achieve this, biodigital architecture aims to transform the built environment into part of the natural world and its ecosystems through a combination of bio-intelligence and biotechnological tools.

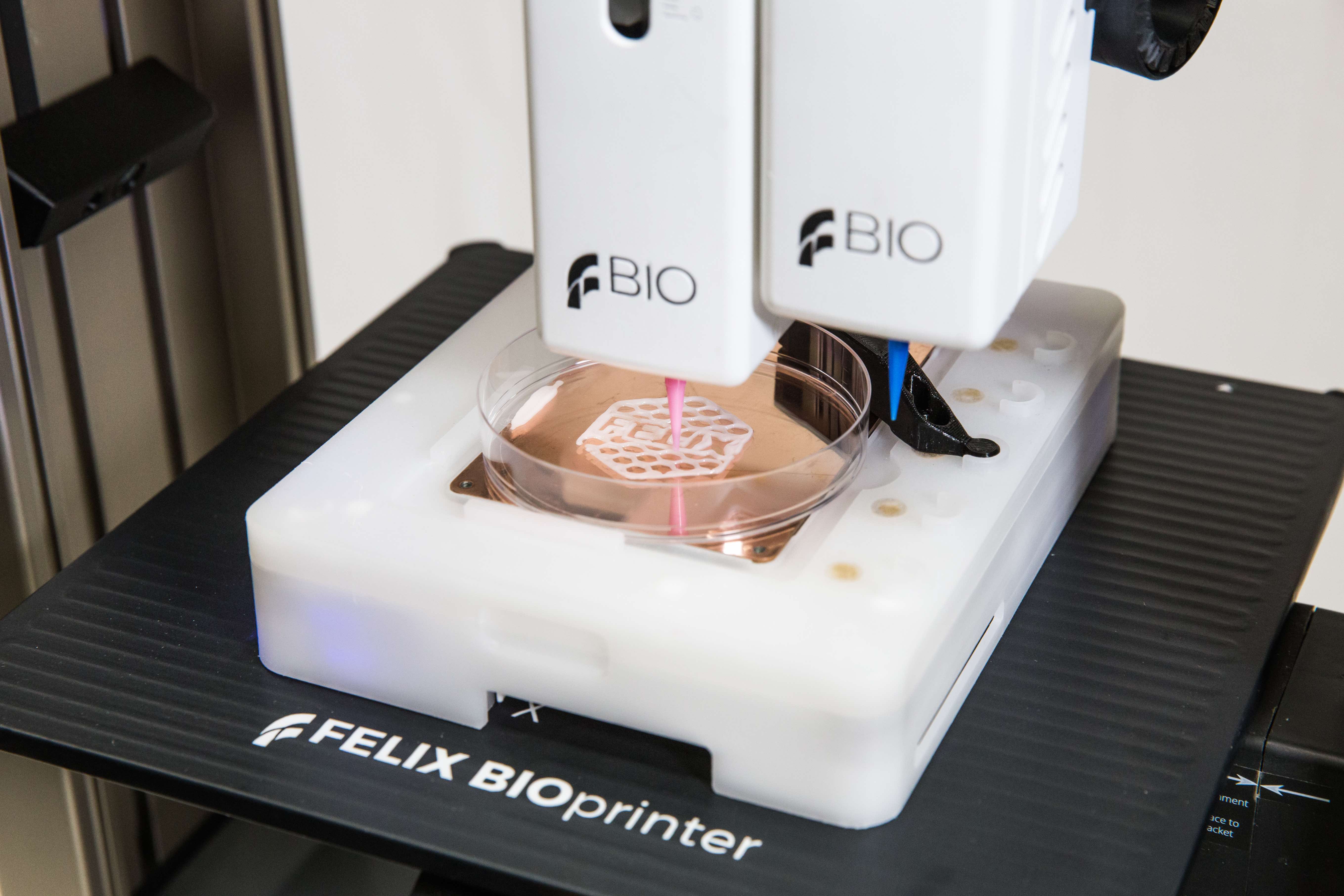

Supporting the researchers in their mission is FELIX’s 3D BIOprinter, which is helping to develop a library of new 3D printable living biomaterials to be used as architectural materials for both functional and ecologic purposes.

Biodigital architecture

Biodigital architecture brings together intelligence from nature and computational-based technology and applies this to the built environment. The aim of iBAG-UIC’s research is to create “living” architecture that encompasses intelligent biological agents and systems.

To achieve this, the institute will deploy a combination of biotechnical tools, such as culturing bacterial and fungal strains to produce building materials and specific DNA editing, digital design tools like 3D modeling, and bio-fabrication tools including 3D printing, robotic manufacturing, and CNC milling.

By utilizing all of these technologies together, iBAG-UIC hopes to create architecture that is equipped with natural bio-intelligence, enabling it to become part of the surrounding natural environment.

The role of FELIX’s 3D bioprinter

In one form or another, iBAG-UIC has been using FELIX’s printers for more than six years, claiming to be one of the first to integrate 3D printing technologies into the architectural design and manufacturing process.

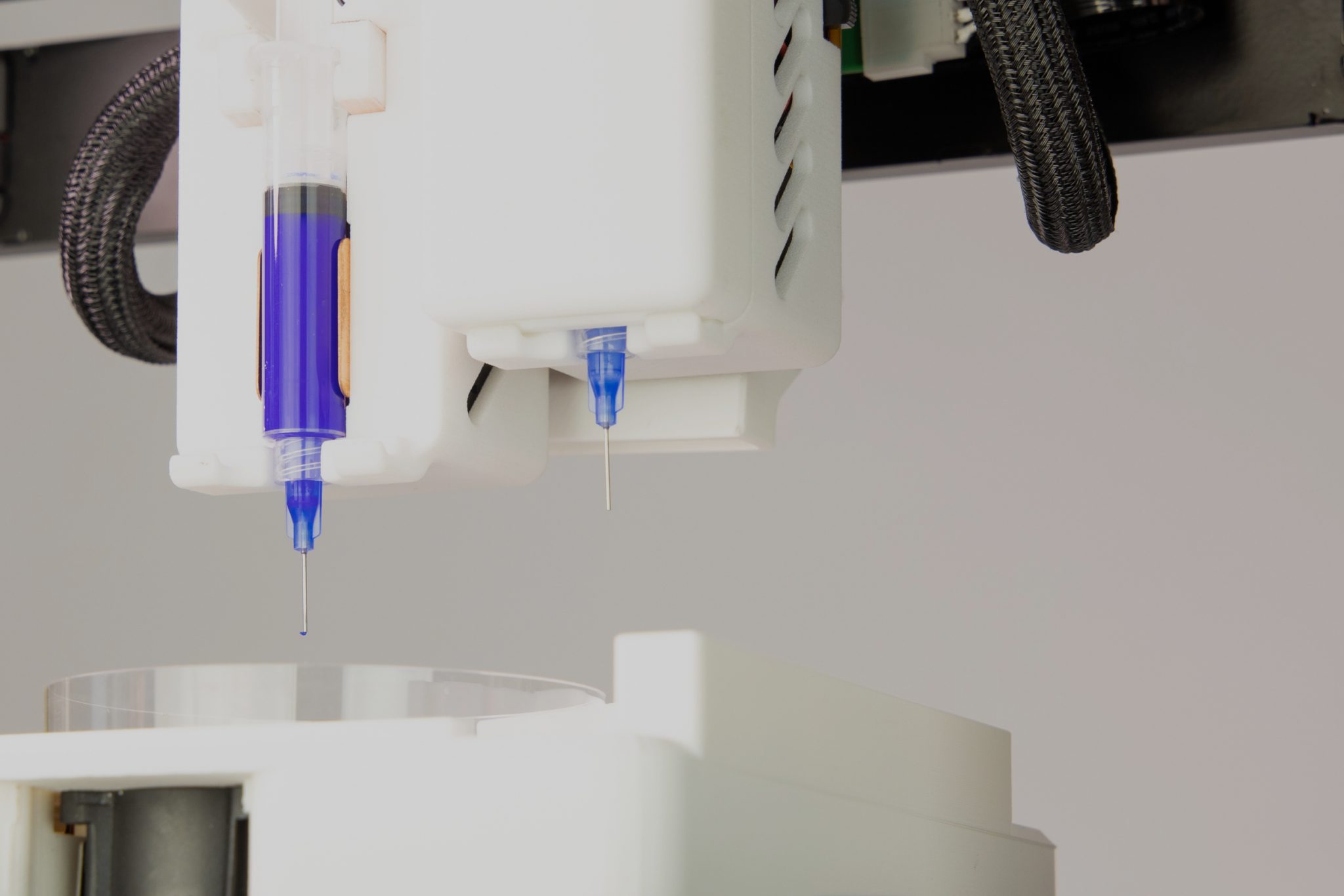

Within its current research, the institute is using FELIX’s BIOprinter to develop various printable bioactive tissues suitable for architecture applications. During the pre-printing phase of the process, various bio-inks are optimized for cell viability and proliferation. The printability of these customized bio-inks is then experimented with during the 3D printing phase, which examines rheological properties such as cross-linking and speed during the printing and post-printing process.

FELIX’s BIOprinter enables the control and adjustment of the biomaterials’ chemical, physical, and structural properties through its dual head extruder. The ability to print multiple bio-inks within the same printing process increases the opportunity for further experimentation and customization of the biomaterial tissues. This then allows the researchers to optimize certain bio-inks for particular functional applications.

The BIOprinter’s high-resolution and geometric precision also enables the institute to customize the chemical and physical properties of the biomaterial tissues at nano and microscale levels. The printer’s highly sterile printing conditions maintain the viability of living cells within the bio-inks.

During the post-printing phase, the researchers investigate how altering the proliferation, differentiation, functionality, morphogenesis, and independent pathways of the printed biomaterials affect their cellular behavior as they are scaled up to the macro level. The researchers are also able to explore the potential architectural applications for the biomaterials in real-time and under real operating conditions.

These stages are helping the iBAG-UIC to develop a library of new living biomaterials able to be used for multiple architectural uses. The collaboration between iBAG-UIC and FELIX is in the process of scaling up on an international level with the opening of biomanufacturing labs in Sharjah, UAE, and Barcelona.

FELIX and 3D printing

FELIX moved into the 3D bioprinting market earlier this year with the announcement of the commercial availability of its BIOprinter, which was first introduced by the firm during 2019’s Formnext exhibition. The printer was developed in partnership with Training4CRM and the Technical University of Denmark (DTU), with funding from the European Union Horizon 2020 Programme.

Since its conception in 2010, FELIX has become known for its Pro series of desktop 3D printers. In 2015, FELIX released the FELIX Pro 1, which was soon followed by the FELIX Pro 2, winner of the “Personal 3D Printer of the Year (FFF/FDM)” category in the 2017 3D Printing Industry Awards. The company released its Pro 3 printer at the start of 2019, followed by two large-format FDM/FFF printers, the Pro L and Pro XL, a few months later.

Looking ahead, FELIX will continue to collaborate with the iBAG-UIC on projects that have “strong moral and ethical credentials”, and will seek to foster further research and development within the area of 3D bioprinting.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows The FELIX BIOprinter. Image via FELIXprinters.