It seems to me that – as complex as it may be – we are going to be able to 3D print working organs before we 3D print a working smartphone as a single unit. That’s because, at least the organs will be 3D printed using stem cells, while to 3D print a working telephone we are going to have to develop new plastic hybrid conductive materials that do not exist yet. Of course it is not really this simple but the fact of the matter is that bioprinting is taking off, and it is not all that different from desktop FDM 3D printing.

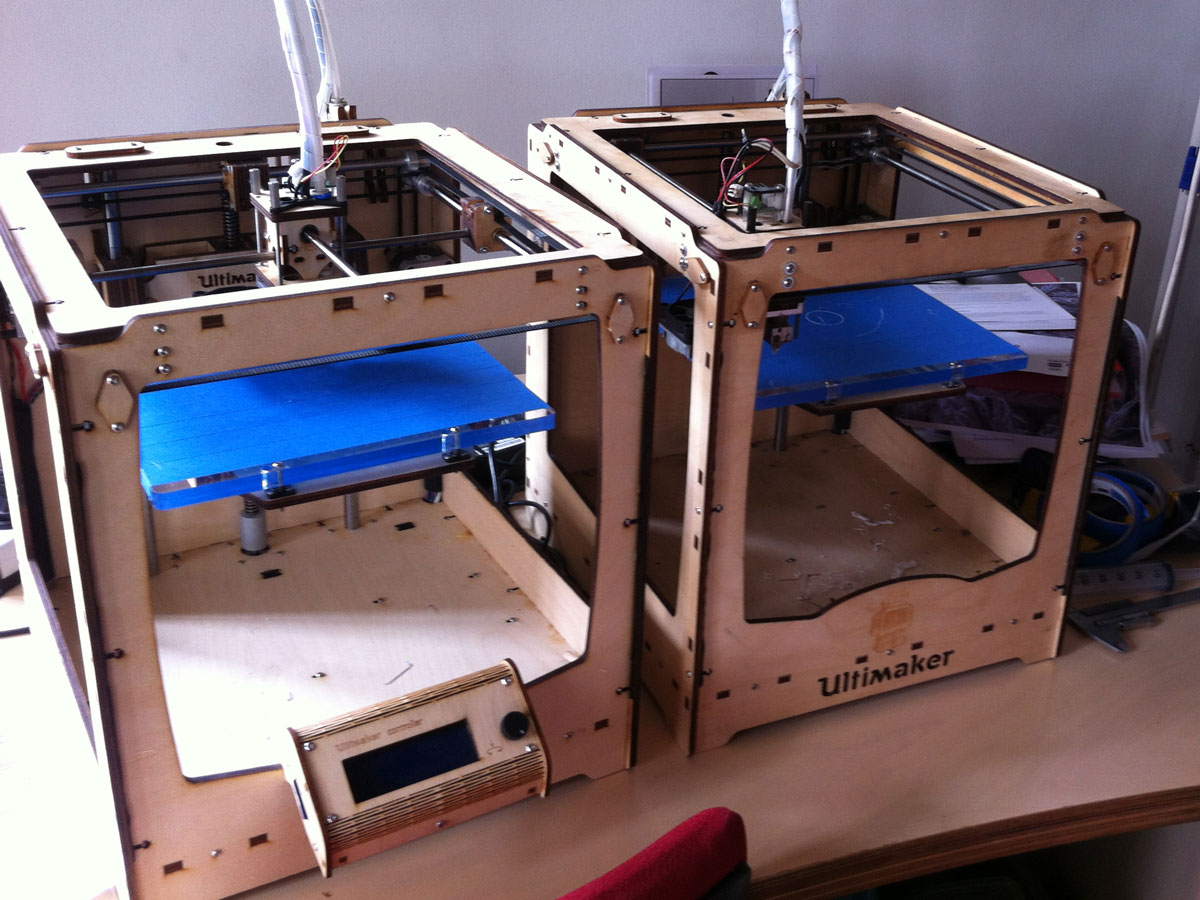

So much so that here in the Netherlands, one of the original hubs for personal and consumer 3D printing, there is a lot of thought being given to bioprinting. Utrecht University is holding a 3D printing to bioprinting summer course while the FabLab Amsterdam, one of the very first ever opened, has set up an entire wet-lab. That is a “laboratory where chemicals, drugs, or other material or biological matter are handled in liquid solutions or volatile phases” (thank you, Wikipedia). And what do you find inside it? Two Ultimakers, of course. I am in the Netherlands, after all.

The most curious aspect of it is that they are not even Ultimaker 2’s. An Ultimaker original will do just fine with pastes and gels in a syringe extruder. The main difference between this and a corporate wet lab is that you will find open source everywhere. Even a very interesting OpenPCR machine. Also known as a thermal cycler, it is a machine that amplifies DNA (again, thanks, Wikipedia) via the polymerase chain reaction (PCR). What it does is basically create thousands of millions of copies of a particular strand of DNA.

I have relatives who have worked in the pharmaceutical industry who do not think open source methods could ever work in drug research due to the millions it costs to test and produce new drugs. Things are changing. All paradigms come into question but will they all, eventually, fail?

The FabLab in Amsterdam is a great place to think about that, since Dave Gonner, who was kind enough to show me around, explained that it was set up in the Waag, an old building (over 400 years) that used be home to the guilds. An ancient ‘fab lab’ (like Volcano’s under Mt. Etna before that); and now electronics and digital fabrication are an integral part of it. And digital biotechnology too.

The Waag society, a non-profit organization for the promotion of arts, science and technology, that hosts the FabLab Amsterdam, has been paying a lot of attention to DIY bio, in fact it even compiled a report on it for the Dutch government, where it identified four main areas: hobbyism, activism, art and science. That’s what the FabLab does. The organization’s goal, in general, is to help bring new products to the market. And the FabLab in Amsterdam was created to just help more people do that in all sectors that can benefit from personal digital fabrication tools.

“We have a more artistic approach and tend to follow the people that come to the FabLab to help them understand and learn how to use the many tools available,” says Gonner. “The Lab’s main activities are linked to courses and use of the machines. The number of people joining is fairly steady though awareness needs to grow much more for new generations to become interested and learn how to master the possibilities available to them.”

All 3D printing is done through the Ultimakers and the quality of the output is generally high. One of the most interesting projects I saw, however, was achieved mostly through a personal use of more traditional technology: a Foosball built from scratch, with milled wood, moulded players and even digital LED scoreboards embedded into the wood.

From fun to scientific research, maybe everything can be achieved through open source and digital manufacturing technologies. The bioprinting course in Utrecht next week will help to clarify that further.