Binder jetting 3D printer manufacturer ExOne has announced the launch of its new ExOne Scout app – a secure smartphone and smartwatch app for real-time machine monitoring. The company has also recently qualified Inconel 718 for use with its metal binder jetting systems, bringing ExOne’s list of qualified materials to 22.

The ExOne Scout app

The newly released Scout app serves to deliver push notifications to smart devices regarding print jobs. The app provides users with useful information such as the job status, printhead speed, fluid levels, temperature, humidity, and other relevant data. It is available to download for free on the Apple App Store and the Google Play Store.

Scout is currently compatible with two ExOne 3D printers that are powered by Siemens’ IoT operating system MindSphere. The S-Max Pro is a sand 3D printer used for the production of sand molds while the X1 160Pro is a metal 3D printer that is still in production but expected to ship by the end of the year.

John Hartner, CEO of ExOne, states: “ExOne Scout is an important step forward as we work to deliver on our vision for smart and sustainable 3D printing technology at production volumes. We plan to surround our high-speed binder jet 3D printers with a complete end-to-end digital workflow in the future. While our 3D printers remain the centerpiece, we’re looking to streamline the entire sequence of digital manufacturing around our systems with automation, software and remote monitoring and controls.”

Inconel 718 for binder jetting

Inconel is a nickel-based superalloy typically used in high-stress aerospace, energy, and automotive applications. It is characterized by its high strength, hardness, corrosion and chemical resistance, and ability to withstand extreme temperatures ranging from sub-zero to 700°C. The material also has excellent welding properties, making it a ‘jack-of-all-trades’ among high-performance metals.

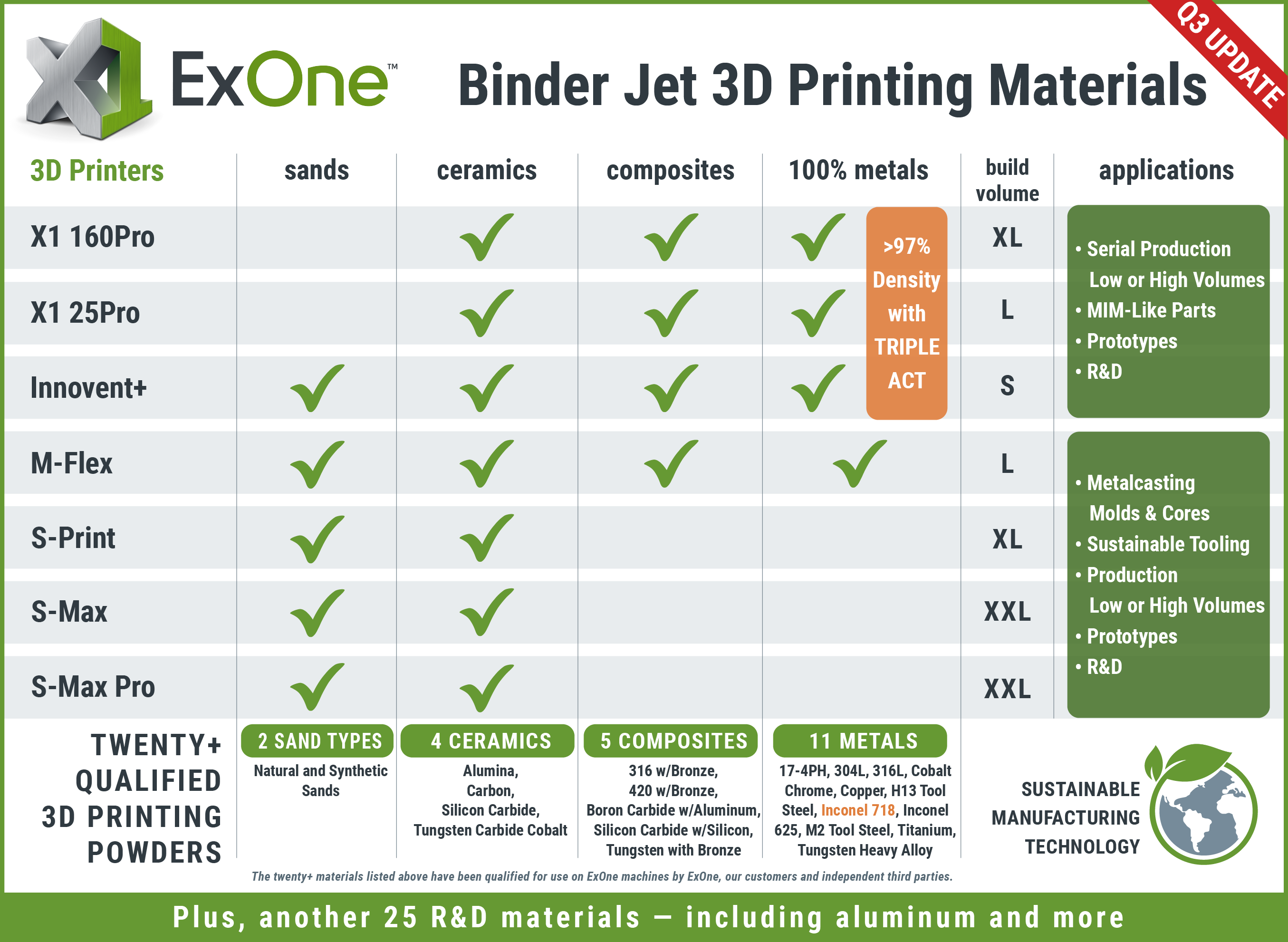

Previously, Inconel 718 was recognized as an R&D material, meaning it was suitable for research purposes and would be supported by ongoing development. It has since gained ExOne’s ‘Third Party Qualification’ status, signifying that it has passed extensive ExOne testing over multiple builds with verified material property data from an independent third party. This is the company’s highest level of material readiness when it comes to metal binder jet 3D printing.

Rick Lucas, ExOne CTO and VP of New Markets, explains: “Today’s qualification of Inconel 718, following on the heels of M2 Tool Steel earlier this year, shows the ExOne R&D team is aggressively delivering new materials for binder jet 3D printing. Our increasing pace of material qualifications is a testament to the strength of our new metal 3D printer systems equipped with Triple ACT, an advanced compaction technology that is essential for binder jetting metals and other materials at high speeds and densities.”

Earlier this month, ExOne released its Q2 2020 financial results. The results indicate that the company generated total revenue of $11.1M, which is down 27.4% compared to the same period last year, where the company’s revenue was reported at $15.3M. Despite an overall drop in revenue, the results showed an increase in revenue from repeat customers, generating a backlog of orders worth $38.2M.

ExOne has also recently been collaborating with academic bodies, as the company announced the commencement of five new projects with Pennsylvania universities to advance various aspects of binder jet 3D printing. Each of the projects will focus on one area of binder jetting, such as the development of new materials or increasing the density of 3D printed parts.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ExOne Scout app. Image via ExOne.