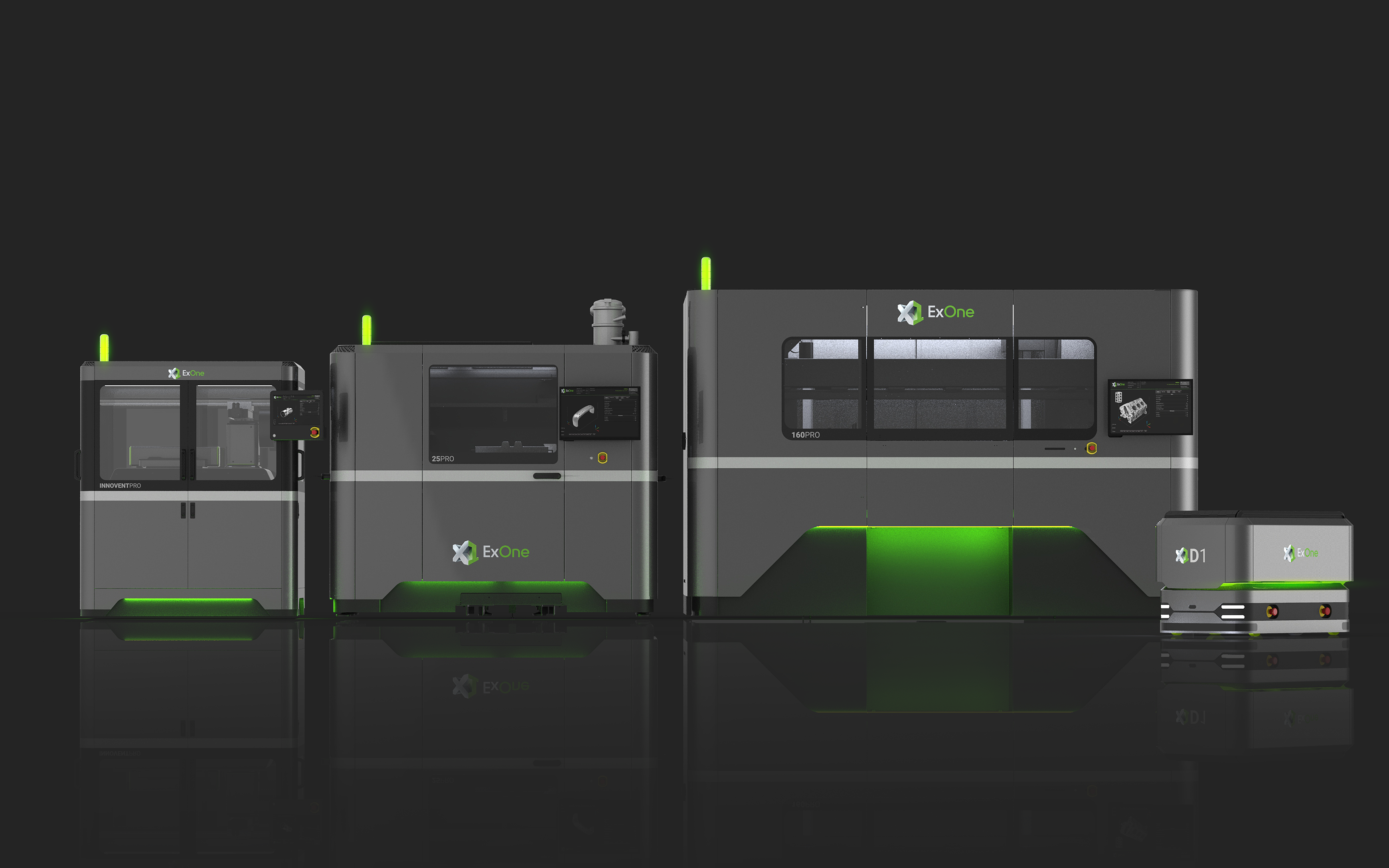

Binder jetting 3D printer manufacturer ExOne has announced the launch of its new InnoventPro metal 3D printer – an updated entry-level binder jetting additive manufacturing system for 3D printing metals, ceramics, and composites. The company has also debuted a concept rendering of its new X1D1 automated guided vehicle, designed to facilitate the efficient transport of 3D printed build boxes through the binder jetting process.

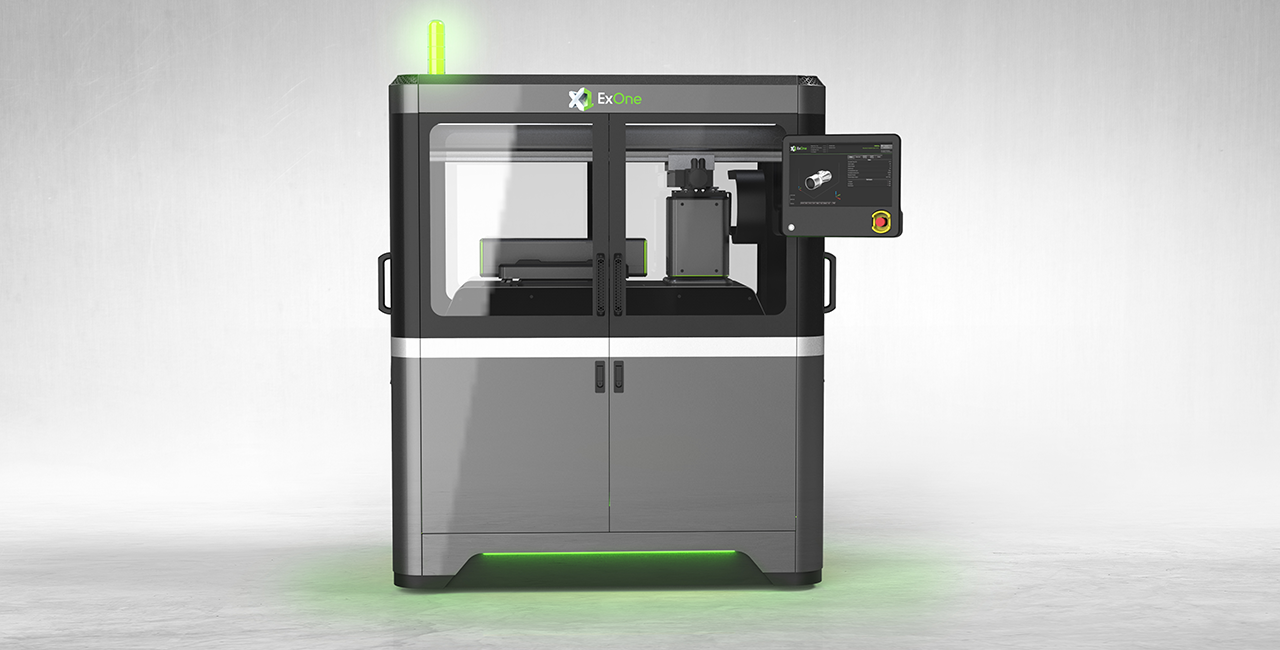

The InnoventPro

The binder jetting process involves selectively depositing a binder onto the powder bed, bonding these areas to form a solid part layer by layer. When printing metals, the final part must be sintered to fully fuse the particles into a solid object.

A considerable upgrade of ExOne’s Innovent+ 3D printer, the InnoventPro offers two new size options; a three-liter and a five-liter build area. The printer can reach print speeds up to 700 cc/hour. Designed with academics, researchers, and a range of manufacturers in mind, the updated system will enable users to produce metal parts quickly, affordably, and sustainably. The latest metal 3D printer rounds out ExOne’s family of production metal binder jetting systems and accessories.

“Customers around the world already love the Innovent+, and based on their feedback, we’re going to give them an updated entry-level system that’s bigger, faster, and smarter than ever,” said John Hartner, ExOne CEO.

The InnoventPro features the same recirculating printhead modules found on ExOne’s X1 25Pro and X1 160Pro metal 3D printers to enable users to scale up R&D activities on the InnoventPro to high volume production. According to ExOne, the upgraded printhead will more than triple speeds, slashing the production cost per part. The printhead also permits the use of particulate binders as an option on commercial binder jetting systems, with the company’s research team having worked with nanoparticles suspended binders for several years.

Nanofuse binders

ExOne’s inkjet-printable nanoparticle suspensions were first patented in 2018 and are now cleared for commercial deployment in the InnoventPro. By their nature, nanoparticles fill the gaps between powder bed particles and bond at lower temperatures to create stronger, ‘green’ parts. As a result, this facilitates the 3D printing of larger parts with finer features, such as sharper corners and edges, alongside improving the resolution and sinterability of metals such as copper and aluminum.

“Just as the current Innovent+ served as the proving ground for our patented Triple ACT system, which now delivers industry-leading quality in metal binder jetting, the InnoventPro will offer groundbreaking new features in a commercial system,” explained Rick Lucas, ExOne CTO, and VP, New Markets. “Our patented approach to 3D printing particulate inks in a print bed is opening new doors in binder jetting.”

ExOne’s Triple ACT system is a critical advanced compaction technology which can deliver final part density of more than 97% with dimensional tolerances in the range of <1%-2.5%, depending on the material used. The technology also provides high consistency, with part variation of 0.3% across the print bed. Additionally, Triple ACT has sped up ExOne’s qualification of new materials; its binder jet systems now process more than 20 metal, ceramic and composite materials, with around half of these being single-alloys.

The company recently announced plans to embark upon five new projects with Pennsylvania universities to advance various aspects of binder jet 3D printing, to expand its research and development efforts.

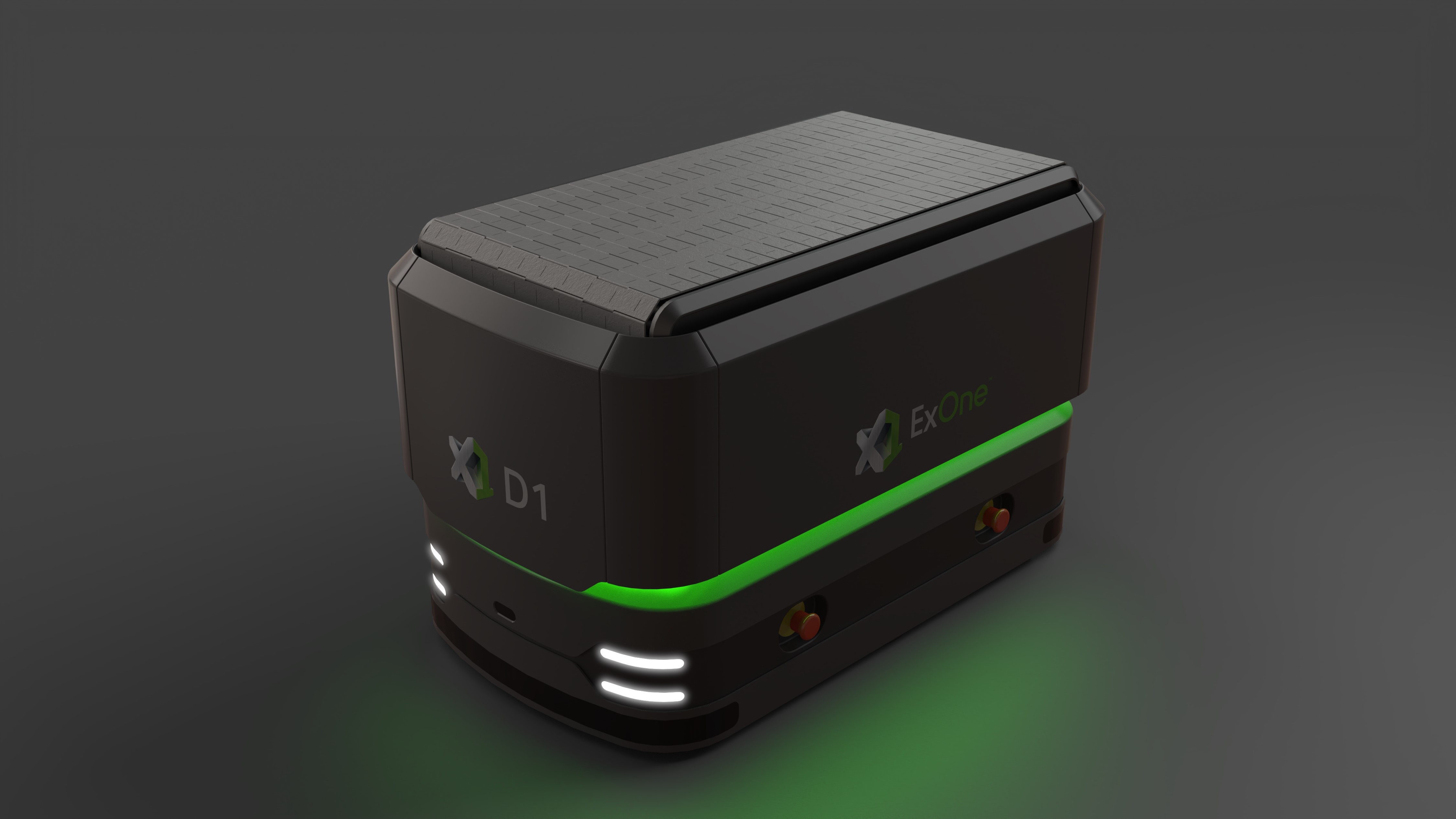

The X1D1 automated guided vehicle

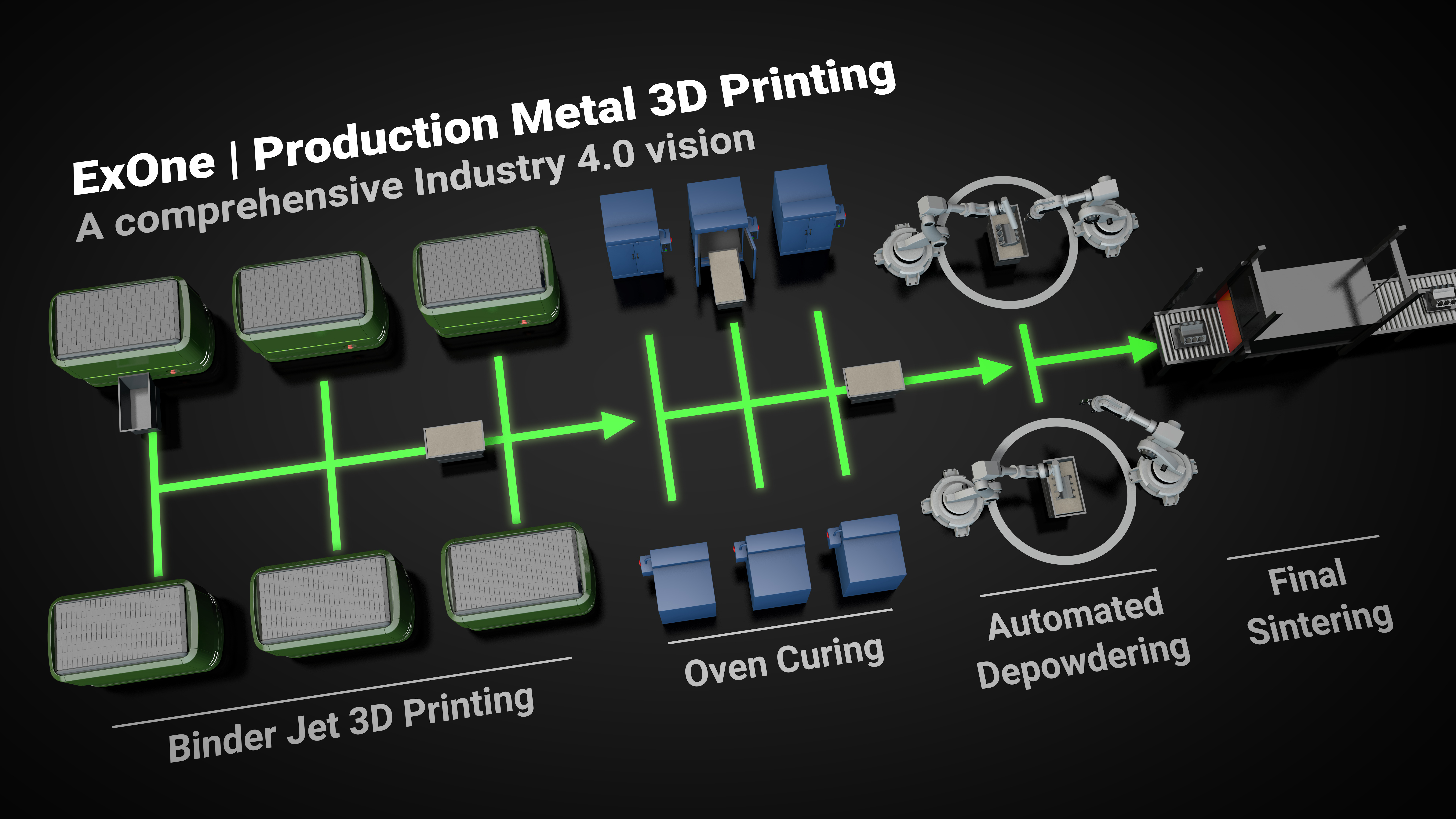

Able to support multiple 3D printers and processes efficiently, The X1D1 automated guided vehicle (AGV) will be offered with ExOne’s X1 160Pro extra-large production metal 3D printer, poised to start shipping to customers later this year. The printer will also be provided with ExOne Scout, the company’s recently-launched Industry 4.0 app, which offers real-time machine monitoring and production analysis on various digital devices, such as smartphones and watches.

“While ExOne’s production metal 3D printers will remain the centerpiece of our digital manufacturing vision, we’re looking to streamline the entire sequence of processes around our systems with automation, software, and remote monitoring control,” said Hartner. “ExOne Scout and the X1D1 are moving us toward a complete digital manufacturing package that is smart and efficient.”

The X1D1 AGV will lock into place at the front of the 160Pro, ExOne’s tenth metal printer and the company’s largest system of its kind, and will be able to roll a build box into and out of the machine. For scale, a full build box of metal powder with a build volume of 160 liters can weigh over 700 kg. After printing, the X1D1 will transport the build box to a curing oven where the parts are dried. They are then moved to an automated depowdering and cleaning station powered by robot arms and other ‘yet-to-be-announced innovations,’ before final sintering.

“As part of our discussion with manufacturers, we’ve updated our vision for the production binder jetting work cell, developing an option that provides high-volume manufacturers with more intelligent flexibility and better use of factory space,” added Hartner.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the InnoventPro (left) is an advanced entry-level metal 3d printer that rounds out ExOne’s full family of production metal binder jetting systems, which includes the X1 25Pro (center), the X1 160Pro (far right), and the X1D1 automated guided vehicle for automated, Industry 4.0 transport. Image via ExOne.