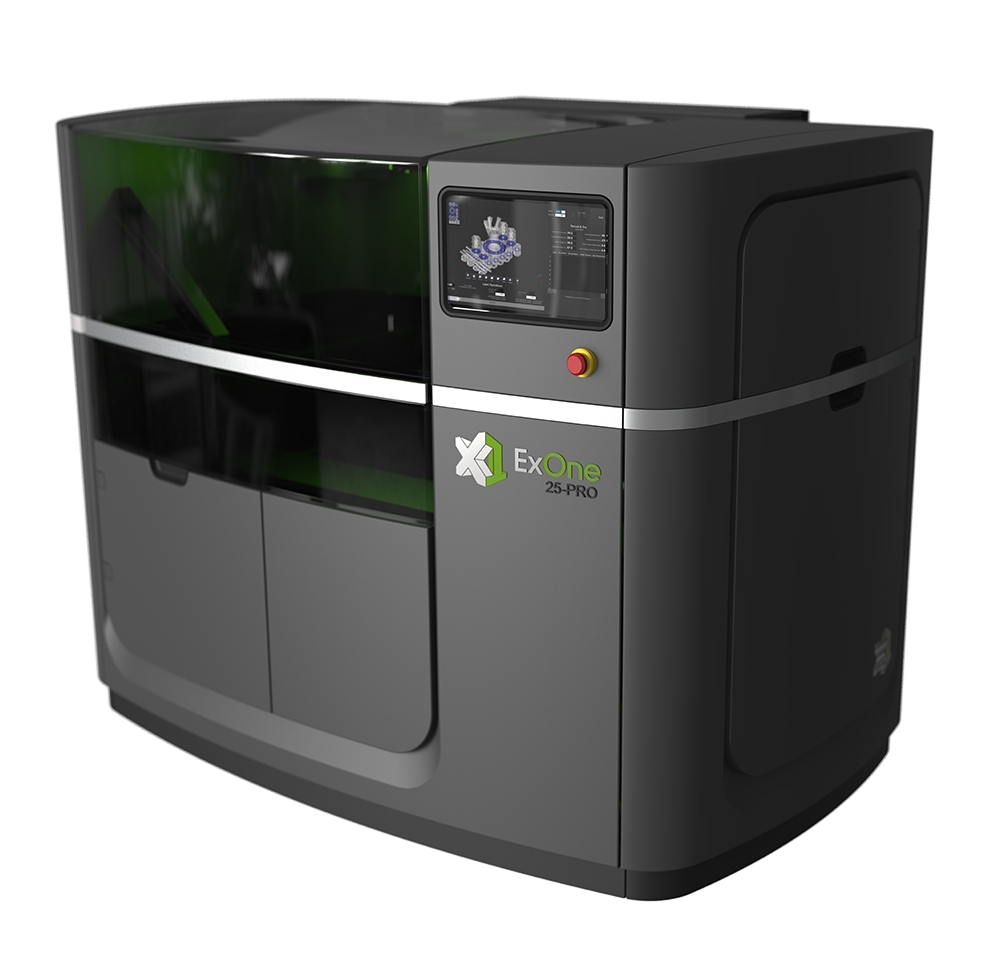

ExOne, a global provider of binder jetting 3D printing systems, services, and materials, has released its latest system, the X1 25 PRO at Formnext.

The X1 25 PRO enables a larger build volume and the equivalent powder metallurgy capabilities powders from ExOne’s INNOVENT+ . The platform is also designed to focus on the Metal Injection Molding (MIM), powder metallurgy, and mechanical engineering market applications.

“Our X1 25 PRO is the first of two machines that we are introducing by the end of the first half of 2019, utilizing our state-of-the-art patent-pending MIM powder processing machine technologies,” said Rick Lucas, Chief Technology Officer at ExOne.

“We believe these new production machines will be the most flexible and highest performing binder jetting machines in the market.”

The X1 25 PRO system

According to Jared Helfrich, Chief Commercial Officer at ExOne, the X1 25 Pro can produce prints using very fine MIM powders of nine microns. The technology is based on the process settings from the INNOVENT+ additive manufacturing system, however, with a larger volumetric output.

The system uses a wide range of MIM powders including 136L, 304 L, and 17-4PH stainless steels; Inconel 718 and 625; M2 and H11 tool steels; cobalt chrome; copper; and tungsten carbide cobalt. It combines these powders with a binder to print a green part, that is then sintered leaving a fully dense part.

With this system, the company aims to accelerate the production of industrial metal components with high resolution, tight tolerances, and improved surface finishes.

The INNOVENT platform

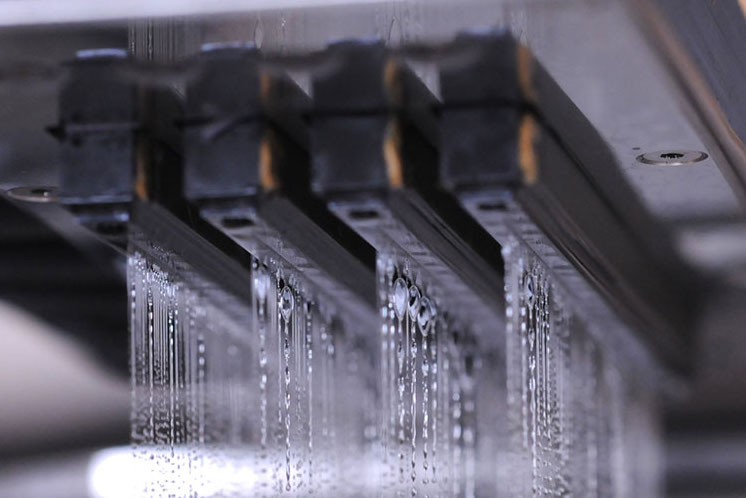

ExOne’s INNOVENT platform relies on a printhead to dispense micro-droplets of specially-engineered binder into very thin layers of powdered metal. The INNOVENT+ system, in particular, is designed for testing purposes and larger scale prototyping or series production. The printer’s build volume measures at 65mm x 160mm x 65mm and is part of a larger system that includes an oven and furnace.

Furthermore, ExOne’s systems are made with material capabilities that encourage development from educational and research institutions. Such materials include engineered sand, bronze, stainless steel, tungsten, titanium, and single-crystal, aerospace materials.

ExOne is currently taking orders for the X1 25PRO system. The 3D printer will also be showcased at the RAPID + TCT show in Detroit on next year.

Make your nominations for the 2019 3D Printing Industry Awards here.

Also, for all the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Make your next additive manufacturing career move or hire new talent. Search and post 3D Printing Jobs on our free jobs service.

Featured image shows the X1 25PRO 3D printer. Photo via ExOne.