UK-based water filtration technology provider Evove has closed a £5.7 million funding round, funded by At One Ventures and AM Ventures.

The round was led by At One Ventures, a frequent investor in disruptive deep tech with sustainability benefits. The funding will aid Evove to increase production capabilities, scale up its 3D printed membrane process, and capitalize on a “large pipeline of possibilities”. Moreover, Evove says that existing investors such as Innovate UK, Imagine H2O, contributed to the round. Evove will concentrate on key products and a well-established customer base in lithium extraction, beverages and food, desalination, water reuse, and ultrapure water.

“We are convinced that Evove is a prime example of how additive manufacturing can transform our world and significantly reduce CO2 emissions in many areas. We back trailblazing entrepreneurs in 3D printing and Evove is at the forefront of precision-engineered filtration membranes that will significantly disrupt the status quo in their markets,” said Johann Oberhofer, Managing Partner at AM Ventures.

“We are thrilled to have received support from At One Ventures and AM Ventures in addition to further investment from our existing investors. This funding will enable us to increase manufacturing capacity and expand our service and support network, enabling us to help end-users solve some of the world’s biggest water and energy challenges,” added Chris Wyres, CEO of Evove.

Transforming lithium supply and green hydrogen with 3D printing

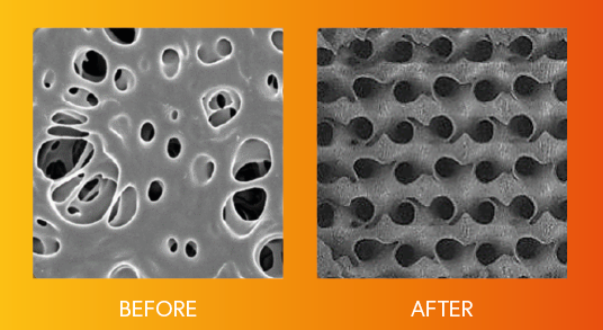

Founded in 2012, and previously known as G2O Water Technologies, Evove is a developer of a graphene-based water filtration technology designed to tackle water shortage. Evove’s technology applies a coating of graphene oxide to polymer membranes used in water filtration, making the membranes more efficient and helping reduce the energy needed to treat the water, enabling businesses, corporates, and energy industry players to find cost-effective services to a variety of filtration needs.

Industries engaged in lithium, desalination, beverages and food, green hydrogen, manufacturing semiconductors, and water reuse have all benefited from Evove’s advanced membrane technology. Evove claims, the establishment of new manufacturing plants in the northwest of England will result in high-paying employment and increased economic activity in the region.

Andrew Greenaway, Chairman of Evove said, “This is an exciting time for Evove, we are grateful for the continued support of our existing investors and delighted to welcome two such highly regarded new investors to the company who bring significant experience of backing high growth technology businesses. Evove’s technology has major applications in multiple global markets where the company already has a significant revenue pipeline working with end-user development partners and I look forward to the next stage of the company’s development with confidence.”

Helen Lin, Partner at At One Ventures said that in order to completely transition to a net zero economy, the industry needs to increase lithium supply and allow for green hydrogen production. “We believe in Evove’s ability to transform these sectors due to the strength of not just its technology but the team. They have a strong track record in delivering growth and investor returns, as well as a passion for creating scalable industrial solutions.”

Cleaner future with 3D printed membranes

Previously, Nano Sun, a Singapore-based start-up, established a 3D printing factory in the hopes of significantly reducing water pollution. The company is a spin-off of Nanyang Technological University (NTU) and makes water filtration membranes using 3D printing. These membranes are five times more effective than the conventional process, which uses polymer and ceramic-based membranes. Nano Sun’s production facility in Tuas can 3D print approximately 600 sq m of membranes. Industrial enterprises utilize water-filtering membranes to remove contaminants from wastewater. Two massive international semiconductor enterprises based in Singapore were among the first customers.

In other news, a German-Dutch consortium comprising industry and science sought to improve the sustainability of plastics production by creating and incorporating 3D printed membranes into the manufacturing process. The Additive Manufacturing for Zero-emission Innovative Green Chemistry project for short (AMAZING), aimed to create a membrane-based process that will isolate byproducts from the plastic manufacturing procedure and render them available for further use. The Institute of Energy and Climate Research, the Institute for Sustainable Process Technology (ISPT), the University of Twente, and the Eindhoven University of Technology collaborated on the project, along with chemical firm BASF, materials science company Dow, and energy company Shell.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows management team of Evove. Image via Evove.